Vacuum Evaporators Market Share, Size, Trends, Industry Analysis Report, By Product (Rotary, Centrifugal, Others); By End-Use (Automotive, Food & Beverage, Energy & Power, Chemical, Pharmaceutical, Electronics); By Technology; By Application; By Regions; Segment Forecast, 2021 - 2028

- Published Date:Apr-2021

- Pages: 118

- Format: PDF

- Report ID: PM1847

- Base Year: 2020

- Historical Data: 2016-2019

Report Outlook

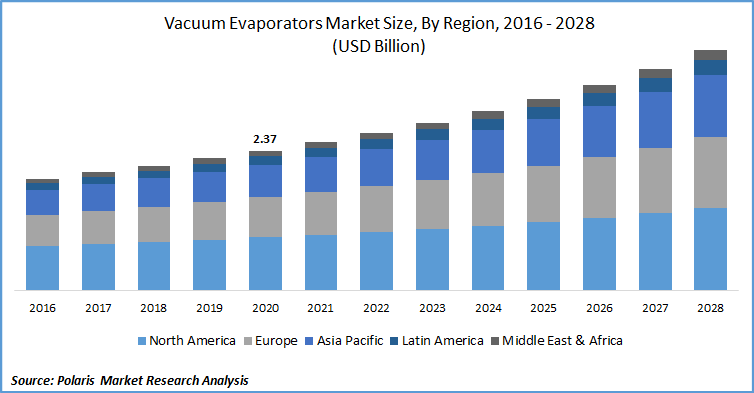

The global vacuum evaporators market size was valued at USD 2.37 billion in 2020 and is anticipated to grow at a CAGR of 7.1% during the forecast period. Vacuum evaporators are increasingly being used for the minimization and treatment of industrial wastewater. Vacuum evaporators function by transforming waste effluent into two streams of high-quality water and concentrated waste. The resultant high-quality water can be re-used, whereas the concentrated waste significantly reduces waste management costs, resulting in enhanced efficiency and energy savings.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Heat pump vacuum evaporators are fully automated to offer complete separation of metals and surfactants. These evaporators are being used as an affordable solution for industrial wastewater recycling and treatment. Heat pump vacuum evaporators offer advantages such as flexibility, low energy consumption, and reliability.

Heat pump vacuum evaporation provides high distillate yield with significant reduction of Chemical Oxygen Demand (COD) through control of foaming phenomena. Heat pump vacuum evaporators are widely used in the food and beverage industry for milk and dairy production and manufacturing of beverages such as tea and juices. The application of heat pump vacuum evaporators has also increased in the wine industry for self-enrichment and dealcoholizing of grapes must.

Industry Dynamics

Growth Drivers

The adoption of multiple-effect evaporators in the market has increased significantly in the automobile industry. Automobile production requires a large amount of water for carrying out manufacturing processes. Vacuum evaporators provide means to obtain clean water from wastewater through conversion into steam. The steam is compressed again to acquire clean water to be reused in the processing plant.

The use of vacuum evaporators enhances material stability while improving overall productivity. Some applications of vacuum evaporators in the automotive industry include oily water evaporation, wastewater treatment, chemical evaporation, plating, and industrial evaporation among others.

The growing automotive industry coupled with an increasing number of passenger and commercial vehicles drives the growth of this market. The rising need to improve manufacturing productivity and growing demand from the food & beverage sector supports the market growth of the vacuum evaporators across the globe.

The introduction of strict industrial emission and environmental regulations has increased the demand for vacuum evaporators from the industrial and manufacturing sectors. The rising industrialization, growing environmental concerns, depleting sources of freshwater, rising adoption of Zero Liquid Discharge Systems, and technological advancements have further accelerated the sale of vacuum evaporators across the globe.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Vacuum Evaporators Market Report Scope

The market is primarily segmented on the basis of product, technology, application, end-use, and region.

|

By Product |

By Technology |

By Application |

By End-Use |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Product Outlook

On the basis of product, the market is segmented into rotary, centrifugal, and others. The market demand for rotary vacuum evaporators has increased in applications such as powder drying, solvent separation from extracts, standard solvent distillations, the concentration of reaction mass or solutions, and crystallization, among others. It is widely used in industries such as petrochemical, pharmaceutical, chemical, cosmetics, and herb extraction, among others.

Technology Outlook

On the basis of technology, the market is segmented into thermal, heat pump, mechanical vapor recompression, and others. The thermal segment accounted for the highest market share in 2020. Thermal evaporators are used for the deposition of metals and nonmetals such as aluminum, chrome, and gold, among others. These evaporators are widely used in industries such as chemical, and food & beverage.

Application Outlook

The application market segment has been divided into laboratory, product processing, wastewater treatment, and others. In 2020, the wastewater treatment segment accounted for the highest market share. The growing water scarcity across the globe, stringent regulations regarding wastewater disposal, and increasing demand for new water resources support the growth of this segment.

End-Use Outlook

On the basis of end-use, the market is segmented into automotive, food & beverage, energy & power, chemical, pharmaceutical, electronics, and others. The automotive segment accounted for the highest market share in 2020. The market growth in the global automotive industry, especially in Europe and Asia Pacific, coupled with the high need for water for automotive manufacturing fuels the growth of this segment. The wastewater generated from automotive production contains a large amount of oil and metallic content, which increases the need for water treatment owing to stringent environmental regulations and proper disposal of wastewater.

Geographic Overview

North America dominated the global vacuum evaporators market in 2020. Increasing industrialization coupled with depleting water resources in the region has fueled the adoption of vacuum evaporators. The demand for vacuum evaporators has increased from industries such as energy & power, pharmaceutical, and food & beverage owing to increased environmental concerns and stringent regulations regarding wastewater disposal. The market growth in manufacturing activities and increasing adoption of zero liquid discharge systems are factors expected to provide market growth opportunities in the region during the forecast period.

Competitive Landscape

The leading players in the vacuum evaporators market include Alfa Laval, Condorchem Envitech, Samsco Corporation, Saltworks Technologies Inc., Sirco Industrial, 3R Technology, Thomas Scientific, Suez Water Technologies & Solutions, Sanshin MFG, De Dietrich Process Systems, JEOL Ltd., Belmar Technologies Ltd., Veolia Water Technologies, Encon Evaporators, H2o GmbH, SPX Flow Inc., 3V Tech S.P.A., and Sasakura Engineering Co., Ltd.