Ultra-Fine Aluminum Hydroxide Market Share, Size, Trends, Industry Analysis Report: By Type (Less than 1μm, 1μm–1.5μm, and 1.5μm–3μm), By Application (Flame Retardant Filler and Smoke Inhibitor, Filler Material, Catalyst, and Others), and By Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Nov-2024

- Pages: 119

- Format: PDF

- Report ID: PM5230

- Base Year: 2024

- Historical Data: 2020-2023

Ultra-Fine Aluminum Hydroxide Market Overview

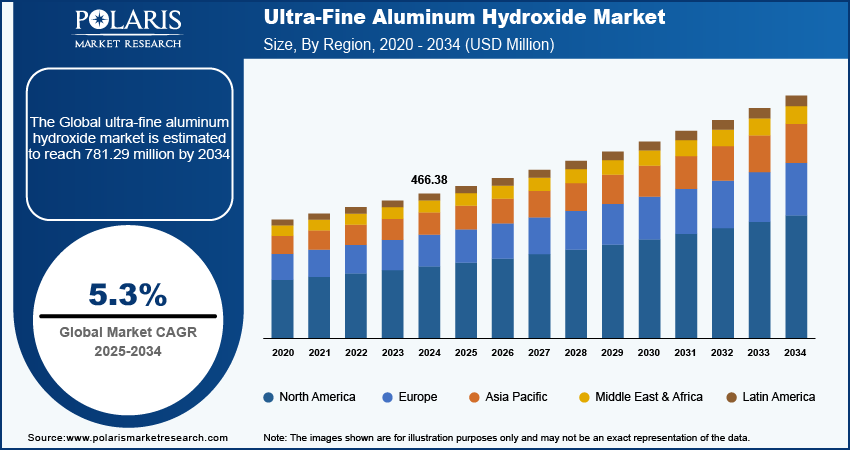

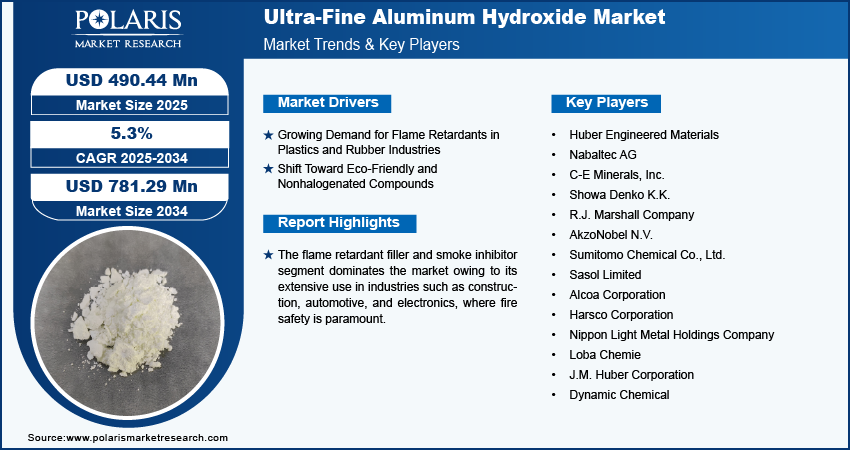

The global ultra-fine aluminum hydroxide market size was valued at USD 466.38 million in 2024. The market is projected to grow from USD 490.44 million in 2025 to USD 781.29 million by 2034, exhibiting a CAGR of 5.3% during 2025–2034.

The global ultra-fine aluminum hydroxide market is experiencing steady growth, driven by its increasing use in the plastics and rubber industries as a flame retardant. In addition, the rising emphasis on safety standards in construction materials and the growing application of ultra-fine aluminum hydroxide in the electronics industry for insulation purposes propel the market growth. Key future trend in the market is the shift toward eco-friendly products, which is expected to encourage the development of aluminum hydroxide-based flame retardants as a safer alternative to halogenated compounds. Additionally, advancements in manufacturing processes are enhancing product quality, further stimulating market growth.

To Understand More About this Research: Request a Free Sample Report

Ultra-Fine Aluminum Hydroxide Market Trends

Growing Demand for Flame Retardants in Plastics and Rubber Industries

The growing demand for flame retardants in the plastics and rubber industries is being driven by increasing safety regulations, rising consumer awareness about fire hazards, and the expanding use of plastic and rubber materials in various applications. Flame retardants are essential for reducing the flammability of materials and improving fire resistance, which is crucial for ensuring the safety of products used in construction, automotive, electronics, and other sectors. In particular, the use of plastics in consumer goods, electronics, and automotive parts has increased significantly, leading to a greater need for flame retardant additives. Additionally, the implementation of stringent fire safety standards in many regions has further boosted the demand for flame retardants.

Shift Toward Eco-Friendly and Nonhalogenated Compounds

The global ultra-fine aluminum hydroxide market is witnessing a noticeable shift toward eco-friendly and nonhalogenated flame retardants, driven by growing environmental concerns and stricter regulatory frameworks. Ultra-fine aluminum hydroxide is emerging as a key material as it offers a viable alternative to traditional halogenated compounds, which are known for their adverse environmental impacts. Consumer preference for greener products and rising efforts by manufacturers to comply with environmental regulations are expected to drive the demand for eco-friendly and nonhalogenated compounds in the coming years. The rising demand for sustainable materials is expected to accelerate the ultra-fine aluminum hydroxide market growth during the forecast period.

Increasing Applications in Electronics Industry

The electronics industry is becoming a major end user of ultra-fine aluminum hydroxide, driven by the material's excellent insulating properties and its ability to act as a flame retardant. As electronic devices become compact and powerful, the need for materials that can provide effective thermal management and fire resistance is rising. Ultra-fine aluminum hydroxide is increasingly being incorporated into electronic components, cables, and connectors to meet the high safety and performance standards required by the industry. This growing application in electronics is a key trend that is expected to contribute significantly to the ultra-fine aluminum hydroxide market expansion.

Ultra-Fine Aluminum Hydroxide Market Segment Insights

Ultra-Fine Aluminum Hydroxide Market – Type Insights

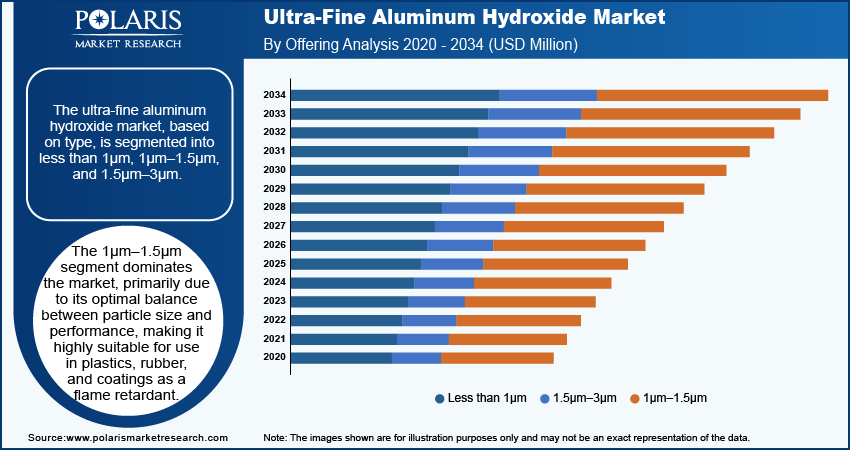

The ultra-fine aluminum hydroxide market, based on type, is segmented into less than 1μm, 1μm–1.5μm, and 1.5μm–3μm. The 1μm–1.5μm segment dominates the market, primarily due to its optimal balance between particle size and performance, making it highly suitable for use in plastics, rubber, and coatings as a flame retardant. Its wide applicability across multiple industries contributes to its leading position in the market. The segment's popularity is also attributed to its ability to enhance the mechanical properties of end products while providing excellent flame retardant capabilities.

The less than 1μm segment is projected to witness the highest growth rate during the forecast period. This growth is driven by the increasing demand for ultra-fine particles in high-performance applications, particularly in the electronics and advanced polymer industries, where the smaller particle size offers superior insulation and flame retardant properties. As industries continue to evolve toward more advanced and specialized applications, the demand for ultra-fine aluminum hydroxide with a particle size of less than 1μm is expected to surge.

Ultra-Fine Aluminum Hydroxide Market – Application Insights

In terms of application, the ultra-fine aluminum hydroxide market is segmented into flame retardant filler and smoke inhibitor, filler material, catalyst, and others. The flame retardant filler and smoke inhibitor segment dominates the market owing to its extensive use in industries such as construction, automotive, and electronics, where fire safety is paramount. This segment's dominance is attributed to the growing demand for nontoxic, environmentally friendly flame retardants that comply with stringent safety regulations. The ability of ultra-fine aluminum hydroxide to enhance fire resistance while minimizing smoke generation has solidified its leading position in this application category.

The catalyst segment is expected to experience the highest growth rate during the forecast period, fueled by the increasing use of ultra-fine aluminum hydroxide as a catalyst in chemical processes, particularly in the production of synthetic materials and petrochemicals. Its fine particle size and high surface area make it an effective catalyst, improving the efficiency and selectivity of chemical reactions. As industries continue to seek efficient and sustainable catalytic solutions, the demand for ultra-fine aluminum hydroxide in this segment is anticipated to rise in the coming years.

Ultra-Fine Aluminum Hydroxide Market – Regional Insights

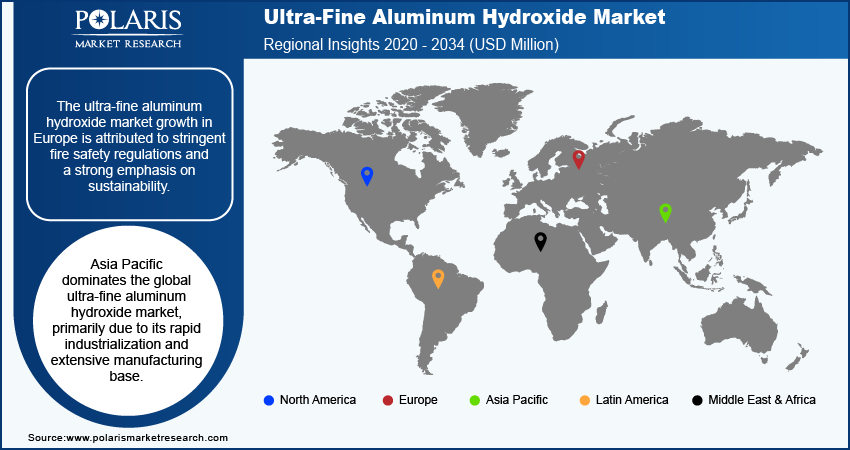

By region, the study provides market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. The ultra-fine aluminum hydroxide market growth in Europe is attributed to stringent fire safety regulations and a strong emphasis on sustainability. European countries have implemented rigorous standards for flame retardants in construction and automotive applications, boosting demand for high-quality, eco-friendly materials. The region's focus on reducing environmental impact and enhancing safety features in various products aligns with the properties of ultra-fine aluminum hydroxide, which is valued for its nontoxic and effective flame retardant qualities. Additionally, advanced technological infrastructure across the region supports innovation in material applications, further contributing to the European market growth.

Asia Pacific dominates the global ultra-fine aluminum hydroxide market, primarily due to its rapid industrialization and extensive manufacturing base. The growing construction, automotive, and electronics industries across the region drive significant demand for flame retardants and fillers. Countries such as China and India are key contributors, with substantial investments in infrastructure and increased safety regulations fueling the use of ultra-fine aluminum hydroxide. The region’s competitive production capabilities and growing focus on meeting international safety and environmental standards also boost its leading market position.

Ultra-Fine Aluminum Hydroxide Market – Key Players and Competitive Insights

Alumina Limited; Huber Engineered Materials; Nabaltec AG; C-E Minerals, Inc.; Showa Denko K.K.; R.J. Marshall Company; AkzoNobel N.V.; Sumitomo Chemical Co., Ltd.; Sasol Limited; Alcoa Corporation; Harsco Corporation; Nippon Light Metal Holdings Company; Loba Chemie; J.M. Huber Corporation; and Dynamic Chemical are a few key players operating in the ultra-fine aluminum hydroxide market. These companies are pivotal in driving innovation, quality, and production efficiency within the market, offering a range of ultra-fine aluminum hydroxide products tailored to diverse industrial applications.

In terms of competitive analysis, the market is characterized by a high level of competition among key players, who vie for market share through technological advancements, product differentiation, and strategic partnerships. Major players are investing in research and development to enhance product performance and expand applications, with a particular focus on improving flame retardant properties and developing eco-friendly alternatives. Companies are also pursuing strategic mergers and acquisitions to strengthen their market presence and diversify their product portfolios.

Insights reveal that while established players dominate the market due to their extensive experience and comprehensive product lines, there is growing competition from emerging firms that focus on niche applications and innovative solutions. The emphasis on sustainability and regulatory compliance is shaping the competitive landscape, driving companies to adopt greener practices and comply with increasingly stringent environmental standards. This dynamic environment underscores the importance of continuous innovation and strategic positioning for maintaining a competitive edge in the ultra-fine aluminum hydroxide market.

Huber Engineered Materials is a significant player in the ultra-fine aluminum hydroxide market, renowned for its high-quality flame retardants and fillers. The company leverages its extensive expertise in materials science to deliver advanced solutions that meet stringent safety and environmental standards. Huber is noted for its strong research and development capabilities, which drive innovation in ultra-fine aluminum hydroxide products.

Nabaltec AG is another key player, known for its production of ultra-fine aluminum hydroxide and other specialty chemicals. The company focuses on delivering high-performance materials for applications such as flame retardants, fillers, and catalysts. The company is recognized for its commitment to sustainability and product quality.

Key Companies in Ultra-Fine Aluminum Hydroxide Market

- Huber Engineered Materials

- Nabaltec AG

- C-E Minerals, Inc.

- Showa Denko K.K.

- R.J. Marshall Company

- AkzoNobel N.V.

- Sumitomo Chemical Co., Ltd.

- Sasol Limited

- Alcoa Corporation

- Harsco Corporation

- Nippon Light Metal Holdings Company

- Loba Chemie

- J.M. Huber Corporation

- Dynamic Chemical

Ultra-Fine Aluminum Hydroxide Industry Developments

- In July 2023, Huber Engineered Materials announced an expansion of its manufacturing capabilities in the US to meet the growing demand for flame retardants in various industries.

- In April 2024, Nabaltec AG unveiled a new ultra-fine aluminum hydroxide product line designed to enhance fire safety and performance in high-demand applications, strengthening its market position and innovation portfolio.

Ultra-Fine Aluminum Hydroxide Market Segmentation

Ultra-Fine Aluminum Hydroxide Market – Type Outlook

- Less than 1μm

- 1μm–1.5μm

- 1.5μm–3μm

Ultra-Fine Aluminum Hydroxide Market – Application Outlook

- Flame Retardant Filler and Smoke Inhibitor

- Filler Material

- Catalyst

- Others

Ultra-Fine Aluminum Hydroxide Market – Regional Outlook

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Ultra-Fine Aluminum Hydroxide Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 466.38 million |

|

Market size value in 2025 |

USD 490.44 million |

|

Revenue forecast in 2034 |

USD 781.29 million |

|

CAGR |

5.3% from 2025 to 2034 |

|

Base year |

2024 |

|

Historical data |

2020–2023 |

|

Forecast period |

2025–2034 |

|

Quantitative units |

Revenue in USD Million and CAGR from 2025 to 2034 |

|

Report coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments covered |

|

|

Regional scope |

|

|

Competitive landscape |

|

|

Report format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global ultra-fine aluminum hydroxide market size was valued at USD 466.38 million in 2024 and is projected to grow to USD 781.29 million by 2034.

The global market is projected to register a CAGR of 5.3% during 2025–2034.

Asia Pacific accounted for the largest share of the global market in 2023.

Key players in the ultra-fine aluminum hydroxide market are Alumina Limited; Huber Engineered Materials; Nabaltec AG; C-E Minerals, Inc.; Showa Denko K.K.; R.J. Marshall Company; AkzoNobel N.V.; Sumitomo Chemical Co., Ltd.; Sasol Limited; Alcoa Corporation; Harsco Corporation; Nippon Light Metal Holdings Company; Loba Chemie; J.M. Huber Corporation; and Dynamic Chemical.

The 1µm–1.5µm segment dominated the market in 2023.

The flame retardant filler and smoke inhibitor segment accounted for the largest market share in 2023.

Ultra-fine aluminum hydroxide is a refined form of aluminum hydroxide with particle sizes significantly smaller than traditional grades, typically less than 1 micron. It is a white, powdery substance used predominantly as a flame retardant and filler in various applications such as flame retardant, coatings and paints, water treatment, and others. Due to its fine particle size, it provides enhanced performance in terms of thermal stability and fire resistance.

A few of the key trends observed in this market are described below: Increased Demand for Eco-Friendly Materials: Growing emphasis on sustainability and regulatory pressures are expected to drive the demand for nontoxic, environmentally friendly flame retardants. Advancements in Manufacturing Technology: Innovations in production techniques will enhance the quality and performance of ultra-fine aluminum hydroxide, making it more effective and versatile. Expansion in Electronics and Automotive Industries: Rising use in electronics for insulation and in automotive applications for enhanced fire safety are projected to boost market growth. Shift Toward High-Performance Applications: Increased focus on high-performance materials in construction and other industries would drive the demand for ultra-fine aluminum hydroxide due to its superior properties.

To stay ahead of the competition, a new company entering the ultra-fine aluminum hydroxide market must focus on developing innovative, eco-friendly products that can comply with stringent safety and environmental standards. Emphasizing advanced manufacturing technologies to enhance product performance and reduce costs can provide a competitive edge. Targeting emerging markets with tailored solutions and forming strategic partnerships can also drive growth. Additionally, investing in research and development to explore new applications and improve the efficiency of ultra-fine aluminum hydroxide will help differentiate the company and address evolving industry needs.

Companies manufacturing ultra-fine aluminum hydroxides and related products, healthcare providers, and other consulting firms must buy this report.