Thermoplastic Polyolefin (TPO) Market Share, Size, Trends, Industry Analysis Report, By Type (Polyethylene, Polystyrene, Polypropylene); By Application; By End-Use Industry; By Region; Segment Forecast, 2022 - 2030

- Published Date:Aug-2022

- Pages: 118

- Format: PDF

- Report ID: PM2543

- Base Year: 2021

- Historical Data: 2018-2020

Report Outlook

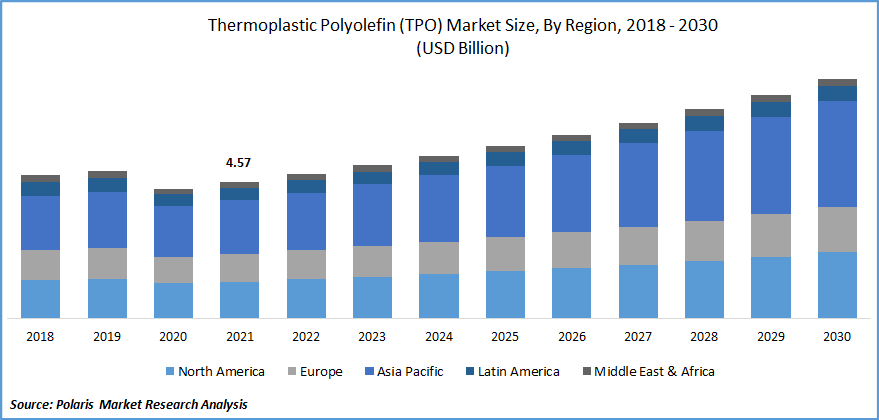

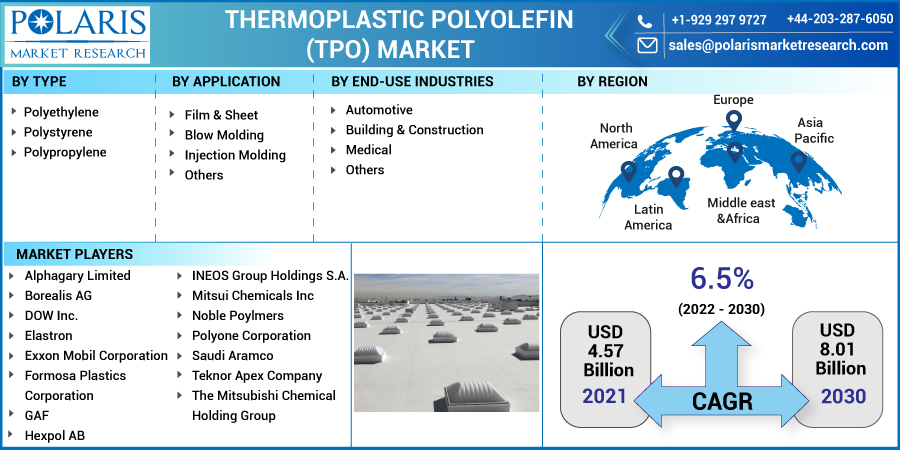

The global Thermoplastic Polyolefin (TPO) market was valued at USD 4.57 billion in 2021 and is expected to grow at a CAGR 6.5% during the forecast period. Thermoplastic polyolefin is an amalgamation of thermoplastic, rubber, and filler. Thermoplastic polyolefin is usually used in the automotive industry and is lightweight and chemical resistant. The Thermoplastic polyolefin (TPO) is easily processed in film & sheet, blow molding, injection molding, and other applications.

Know more about this report: Request for sample pages

High-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and low-density polyethylene (LDPE) are the three major types of polyethylene available in the industry. Major applications of HDPE are blow molding, extrusion nonpackaging, and extrusion packaging. LDPE is used in applications such as toys, films, utensils, bottles, pipes, and processing equipment, whereas LLDPE is used in pouches, cable jacketing, geomembranes, flexible tubing, pipes, and containers.

The COVID-19 pandemic had an overall impact on the global Thermoplastic Polyolefin (TPO) market and its opportunities. The demand for thermoplastic polyolefins depends on the GDP or economic growth of countries. The outbreak of COVID-19 decreased economic activities and hampered the GDP, which resulted in decreased demand. The prices for crude oil decreased significantly in the first quarter of 2020, owing to the halting of industrial activities, which, in turn, declined the prices for thermoplastic polyolefins. However, the second quarter of 2020 witnessed some improvement in prices of crude oil and, consequently, thermoplastic polyolefins, as governments will start relaxing norms around the world for resuming industrial and business activities.

Furthermore, due to the ongoing pandemic, the demand for syringes has increased, and companies such as Hindustan Syringes & Medical Devices Ltd. (HMD) are heavily investing to increase their production capacity to meet the increasing consumer demand. This sudden increase in demand for syringes is anticipated to eventually escalate the need for polypropylene. In addition to this, governments are investing more funds in the production of syringes, which notably contributes toward the growth of the overall industry.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The Thermoplastic Polyolefin (TPO) market is expected to have substantial growth due to the rising demand for TPOs in the healthcare and pharmaceutical sector. The TPOs are used in a wide range of pharmaceutical packaging solutions, such as container and closure systems. However, with regulatory scrutiny toward the use of plastics in the healthcare sector, economic uncertainty, and consumer sensitivity, the usage of thermoplastic polyolefin in healthcare applications continues to grow.

In addition, the prices for raw material used for thermoplastic polyolefin fluctuates. The cost of the product is directly proportional to the cost of the raw material used. The thermoplastic polyolefin industry is strongly influenced by the changes in the prices of raw materials and commodities. Volatility in the price of raw materials is an obstacle in the production of polyalkenes, owing to the fact that if the price of raw material increases, the cost also escalates. Thereby hampering the growth of the Thermoplastic Polyolefin (TPO) market.

Report Segmentation

The market is primarily segmented based type, application, end-use industry, and region.

|

By Type |

By Application |

By End-use Industry |

By Region |

|

|

|

|

Know more about this report: Request for sample pages

Polyethylene segment is expected to dominate the market during the forecast period

By type, the Thermoplastic Polyolefin (TPO) market is segmented into polyethylene, polystyrene, and polypropylene. The industry for the polyethylene segment is expected to dominate the market during the forecast period.

Polyethylene is a light, versatile synthetic polyalkene made from the polymerization of ethylene. It is used in numerous applications, such as shopping bags, clear food wraps, automotive fuel tanks, and surfactant bottles. Polyethylene is produced by the polymerization of ethylene monomers. Metallocene and Ziegler-Natta catalysts are utilized to carry out the polymerization of polyethylene.

Injection & molding is expected to be the fastest growing segment during the forecast period

By application, the Thermoplastic Polyolefin (TPO) market is segmented into film & sheet, blow molding, injection molding, and others. Among these, injection molding is expected to be the fastest growing segment during the forecast period.

Injection molding is a process of gaining molded plastic products by injecting plastic materials in molten form into a mold and subsequently solidifying them. A mold is a vacant metal block into which molten plastic is inserted to form a specific shape. Injection molding is one of the most common applications of thermoplastic polyalkenes. This process involves the manufacturing of identical plastic products in huge volumes. Some of the major manufacturers of injection molding machines are Husky Injection Molding Systems LTD., Arburg GmbH + CO KG, Engel Austria GmbH, and UBE Industries, LTD.

Automotive segment is expected to dominate the market during the forecast period

The automotive segment accounted for a significant share of the global market in 2021. Greater penetration of passenger vehicles and rising adoption of lightweight & high-performing vehicles drive the growth of this segment. The increase in the adoption of electric and hybrid vehicles and the introduction of stringent regulations regarding carbon emissions have increased the demand for thermoplastic polyolefin from the automotive sector.

Initiatives taken by governments to promote the adoption of electric and hybrid vehicles worldwide and the launch of technologically advanced and affordable electric vehicles by market players are factors expected to offer growth opportunities during the forecast period.

Asia-Pacific region expected to dominate the market during the forecast period

The presence of a large consumer base for polyalkenes in Asia-Pacific is a major factor contributing toward the growth of the industry. Furthermore, the established healthcare sector and development of the renewable energy industry boost the market growth.

The production of thermoplastic polyolefins in Asia-Pacific was at its lowest in 2020 due to the outbreak of COVID-19, which, in turn, declined the prices for polyalkenes in the same year. This was majorly attributed to a decrease in crude oil prices. In Asia-Pacific, plastic is majorly consumed in the packaging, construction, automotive, and electrical & electronics industries, which acts as the key driving force of the industry.

Furthermore, owing to the outbreak of the COVID-19 pandemic, the demand for packaging increased owing to the rise in penetration of the e-commerce platforms. In addition, the demand for thermoplastic polyalkenes increased in the healthcare sector due to the emergence of the COVID-19 pandemic. Increase in the development of vaccines during the global health crisis has further boosted the demand for polypropylene, as it used in the manufacturing of syringes, vials, and specimen bottle.

Competitive Insight

Some of the major players operating in the global market include Alphagary Limited, Borealis AG, DOW Inc. Elastron, Exxon Mobil Corporation, Formosa Plastics Corporation, GAF, Hexpol AB, INEOS Group Holdings S.A., Mitsui Chemicals Inc, Noble Poylmers, Polyone Corporation, Saudi Aramco, Teknor Apex Company, The Mitsubishi Chemical Holding Group.

The leading players are investing in research & development and technological advancements to offer a wide range of solutions in the market. Development of new products enable these companies to expand their offerings in the market. Partnerships and collaborations enable major market players to strengthen market presence and cater to the growing consumer demands.

Recent Developments

In December 2020, SABIC launched a new polyolefin plastomer-based solution for liquid container with superior leakage resistance. The product launch has strengthened company’s product portfolio.

In September 2019, INEOS launched a new range of Recycl-IN polyolefin products, which incorporate up to 50% of post-consumer recycled polymer in materials that meet the same exacting specifications as virgin material. This product launch has reinforced company’s product portfolio.

In March 2019, Formosa Plastics collaborated with Entec Polymers to offer design and technical solutions aimed at the automotive industry. The partnership leveraged Formosa's lineup of highly specified Formolene polyolefin resins for development of advanced solutions.

Thermoplastic Polyolefin (TPO) Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 4.57 billion |

|

Revenue forecast in 2030 |

USD 8.01 billion |

|

CAGR |

6.5% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Type, by Application, By End-Use Industry, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key companies |

Alphagary Limited, Borealis AG, DOW Inc. Elastron, Exxon Mobil Corporation, Formosa Plastics Corporation, GAF, Hexpol AB, INEOS Group Holdings S.A., Mitsui Chemicals Inc, Noble Poylmers, Polyone Corporation, Saudi Aramco, Teknor Apex Company, The Mitsubishi Chemical Holding Group |