Textile Processing Machinery Market Share, Size, Trends, Industry Analysis Report, By Application (Household and Hone Textiles, Technical Textiles, Garments & Apparels); By Raw Material; By Application; By Region; Segment Forecast, 2024 - 2032

- Published Date:Mar-2024

- Pages: 119

- Format: PDF

- Report ID: PM4757

- Base Year: 2023

- Historical Data: 2019 – 2022

Report Outlook

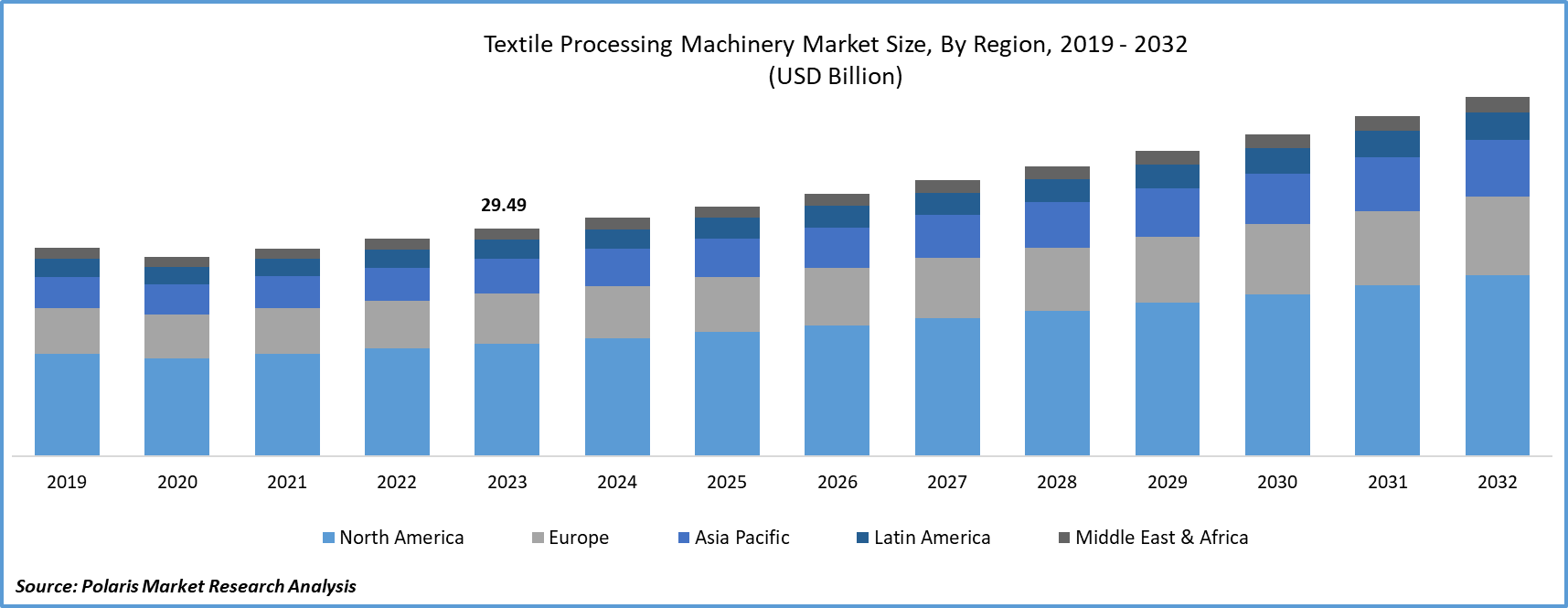

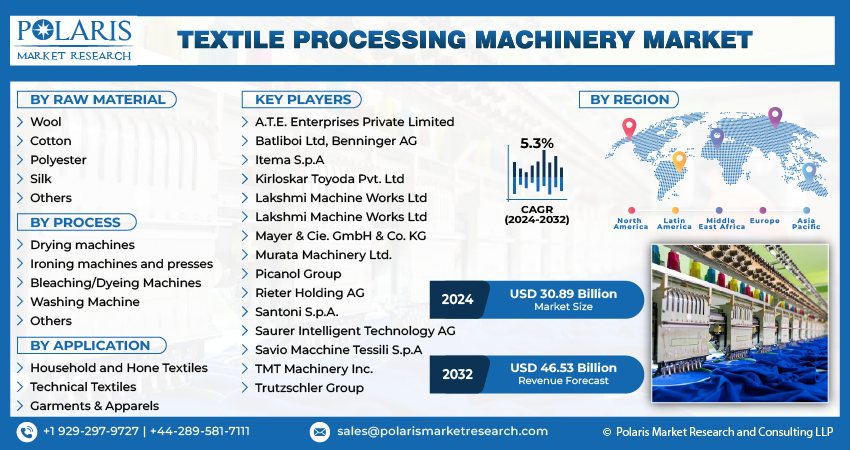

Global textile processing machinery market size was valued at USD 29.49 billion in 2023. The market is anticipated to grow from USD 30.89 billion in 2024 to USD 46.53 billion by 2032, exhibiting a CAGR of 5.3% during the forecast period

Textile Processing Machinery Market Overview

The expansion of the textile industry plays a crucial role in driving global market growth. The enhanced quality of textiles and the flexibility for customization provided by these machines are additional key factors propelling the textile processing machinery market growth. There is a market need for machines that can produce high-quality textiles while accommodating various types of materials. Consequently, the market is experiencing growth driven by the trend of quality assurance and adaptability offered by these machines.

The U.S. textile processing machinery market growth is experienced due to the larger market and advancements in technology market trends. Recent improvements in dyeing machines, washing machines, ironing machines, and drying machines have notably increased efficiency, aligning with sustainability objectives. The affiliation of automated textile processing machines, with the goal of refining process control, reducing waste, and improving facility efficiency, is anticipated to result in a growing ask for textile processing machinery. The increased emphasis on machinery to guarantee product quality and safety has prompted manufacturers in the textile processing machinery sector to make significant investments.

To Understand More About this Research: Request a Free Sample Report

Moreover, new establishments have been inaugurated in the United States to engage in extensive textile manufacturing and concurrently provide recycling services. These aspects indicate the expansion of the U.S. textile processing machinery. The sector is marked by the existence of numerous manufacturers, both large and small, leading to intense competition on both the regional and global fronts.

Additionally, the competitive landscape of the textile processing machinery market is anticipated to play a role in its ongoing growth. Most of these corporations are optimizing their production processes to automation to meet the growing demands of consumers. Furthermore, manufacturers are prioritizing sustainable production practices, aiming for minimal waste and more hygiene. These efforts are expected to drive an increase in product demand in the years to come. The United States stands out as a prominent producer in various textile sectors, including textiles, home furnishings, yarns, fabrics, raw materials, and apparel.

Textile Processing Machinery Market Dynamics

Market Drivers

The Increasing Need for High-Quality Textiles Bolstered the Growth of the Textile Processing Machinery Market Share

Quality assurance stands as a pivotal driver for the textile processing machinery market growth. As consumers increasingly prioritize high-quality textiles, textile manufacturers are compelled to invest in cutting-edge processing machinery to meet these heightened expectations. Advanced machinery equipped with state-of-the-art technologies ensures the production of textiles that adhere to stringent quality standards. This is particularly crucial in industries where precision and uniformity are paramount, such as in the production of apparel, home furnishings, and technical textiles. The adoption of advanced processing machinery not only enables manufacturers to deliver superior products consistently but also enhances their competitiveness in the textile processing machinery market, fostering customer trust and satisfaction.

In the context of textile processing machinery, quality assurance extends beyond just the final product. The machinery itself plays a critical role in ensuring the reliability and repeatability of production processes. Automated systems and smart technologies integrated into these machines contribute to minimizing errors, reducing defects, and maintaining a high level of consistency throughout the manufacturing process. This focus on quality assurance not only satisfies customer expectations but also helps manufacturers streamline their operations, improve overall efficiency, and establish a reputation for producing textiles of exceptional quality. As a result, the emphasis on quality becomes a compelling factor driving the ongoing growth and evolution of the textile processing machinery market.

Market Restraints

High Capital Intensity is Likely to Hamper the Textile Processing Machinery Market Growth

The need for modernization and automation in textile manufacturing processes requires a considerable upfront investment, presenting a financial challenge for manufacturers, especially smaller enterprises. This capital barrier hampers their ability to upgrade machinery, limiting their competitiveness and potentially hindering overall textile processing machinery market growth. The reluctance to allocate substantial resources for cutting-edge machinery impacts the broader textile processing machinery market dynamics as the industry grapples with balancing the imperative to stay technologically current against the financial constraints faced by a diverse range of manufacturers.

Moreover, the rapid pace of technological obsolescence acts as another hindrance in the textile processing machinery market. Manufacturers may be reluctant to invest in current technologies, fearing that their equipment could quickly become outdated with the emergence of even more advanced solutions. This apprehension contributes to a cautious approach to upgrading machinery and adopting the latest innovations. The uncertainty surrounding the longevity and relevance of existing technologies may slow down the adoption rate within the textile industry as manufacturers navigate the challenge of balancing technological advancements with the durability and longevity of their investments.

Report Segmentation

The market is primarily segmented based on raw material, process, application, and region.

|

By Raw Material |

By Process |

By Application |

By Region |

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

Textile Processing Machinery Market Segmental Analysis

By Raw Material Analysis

In 2023, the part of the textile machines that deal with cotton made the most money in the world. This is because there are new and better ways to work with cotton. The machines need to be improved or made specially to do tasks like weaving, ginning, spinning, and finishing with cotton. People are also finding new and better ways to grow and pick cotton, and this affects how cotton is and what machines we need to use. So, the machines need to change to fit the new ways we're working with cotton.

Polyester is expected to grow at the fastest growth rate because of its Versatile, cost-effective, and durable nature. More and more people are using polyester in home stuff, industrial fabrics, and clothes. This means we need special machines that can work well with polyester fibers.

By Application Analysis

In the projected period, the garments and apparel segment dominates the textile processing machinery market. This sector is one of the largest and most varied parts of the textile industry, covering a broad range of items like Stylish textiles, clothes, accessories, and shoes. Since what people like and the latest fashion styles are always changing, manufacturers in this area need machinery that can adapt easily and make a variety of designs, fabrics, and finishes. That's why they require processing machines that are versatile and flexible.

Sustainability is becoming increasingly crucial in the household and home textiles category. Both consumers and brands are leaning towards eco-friendly materials and production methods. Textile processing machinery plays a key role in achieving sustainable manufacturing by enabling processes that save resources, like dyeing with less water, energy-efficient weaving, and making fabrics from recycled materials. This not only helps manufacturers reduce their environmental footprint but also allows them to align with sustainability objectives, appealing to consumers who care about the environment.

Textile Processing Machinery Market Regional Insights

The Asia Pacific Region Dominated the Largest Textile Processing Machinery Market Share in 2023

The textile processing machinery market growth in Asia Pacific is fueled by a rise in foreign investment in the textile and apparel sector, standing out as a key driving factor. Additionally, factors such as a growing population, evolving purchasing habits, rising disposable income, heightened demand for garments and home furnishings, reduced production costs, and affordable labor expenses are the main contributors to the expansion of the regional textile industry.

North America, will grow at the fastest CAGR for adopting the textile processing machinery. The growth is attributed to the increasing industrial manufacturing and a surge in product introductions within the sports and fashion sectors. There is a substantial demand for textile products in both industrial manufacturing and the home textile sector due to the heightened awareness of the applications of technical textiles. These factors are anticipated to boost the need for textile processing machines in the region.

Competitive Landscape

The textile processing machinery market exhibits fragmentation, featuring multiple global and regional manufacturers introducing inventive systems and technologies. Common strategies among industry participants include introducing new products, upgrading existing ones, and expanding operations to increase market presence and adapt to the evolving technical requirements of various application industries. Major players often engage in technical partnerships to foster innovation and create novel product lines, thereby broadening their customer base. Furthermore, anticipated shifts in consumer preferences, coupled with quality standards and a focus on energy efficiency, are expected to present fresh opportunities for key participants in the upcoming years.

Some of the major players operating in the global market include:

- A.T.E. Enterprises Private Limited

- Batliboi Ltd, Benninger AG

- Itema S.p.A

- Kirloskar Toyoda Pvt. Ltd

- Lakshmi Machine Works Ltd

- Lakshmi Machine Works Ltd

- Mayer & Cie. GmbH & Co. KG

- Murata Machinery Ltd.

- Picanol Group

- Rieter Holding AG

- Santoni S.p.A.

- Saurer Intelligent Technology AG

- Savio Macchine Tessili S.p.A

- TMT Machinery Inc.

- Trutzschler Group

Recent Developments

- In September 2023, Santoni Shanghai successfully acquired Terrot, a company specializing in circular knitting machines. This strategic acquisition aligns with Santoni Shanghai's comprehensive plan to establish a sustainable and technologically advanced ecosystem in the knitting machinery sector. The incorporation of Terrot into their portfolio signifies a noteworthy advancement in bringing to life their shared vision of a unified and integrated ecosystem within the industry.

- In June 2023, Trützschler Group introduced its latest machinery and technologies tailored for nonwovens, spinning, artificial fibers, and card clothing. The cutting-edge technology in carding, draw frame and combing specifically targets essential customer requirements in fiber processing, aiming to improve efficiency, promote sustainability in raw material utilization, and incorporate intelligent automation.

Report Coverage

The Textile Processing Machinery market report emphasizes key regions across the globe to provide a better understanding of the product to the users. Also, the report provides market insights into recent developments and trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers an in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides a detailed analysis of the market, focusing on key aspects such as competitive raw materials, processes, applications, and futuristic growth opportunities.

Textile Processing Machinery Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 30.89 billion |

|

Revenue Forecast in 2032 |

USD 46.53 billion |

|

CAGR |

5.3% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments Covered |

By Raw Material, By Process, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

key companies in Textile Processing Machinery Market are AG, A.T.E. Enterprises Private Limited, Lakshmi Machine Works Ltd, Santoni S.p.A., Rieter Holding AG, Trutzschler Group, TMT Machinery Inc

Textile Processing Machinery Market exhibiting a CAGR of 5.3% during the forecast period

The Textile Processing Machinery Market report covering key segments are raw material, process, application, and region.

key driving factors in Textile Processing Machinery Market are increasing need for high-quality textiles

The global textile processing machinery market size is expected to reach USD 46.53 billion by 2032