Screw Compressor Market Size, Share, Trends, Industry Analysis Report: By Type (Oil Free and Oil Injected), Stage, Technology, Power Source, End User, and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Apr-2025

- Pages: 129

- Format: PDF

- Report ID: PM5521

- Base Year: 2024

- Historical Data: 2020-2023

Screw Compressor Market Overview

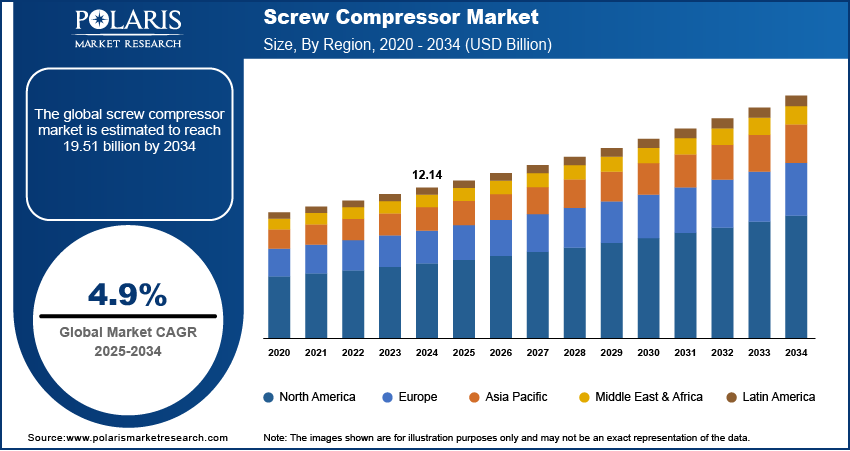

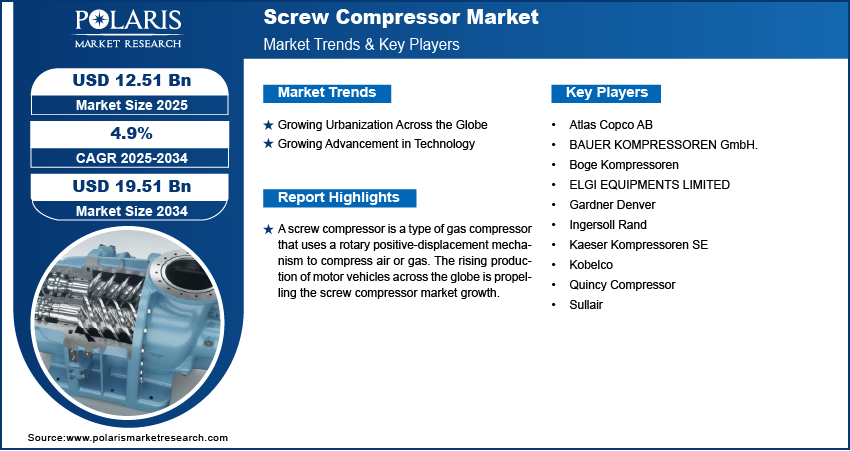

The global screw compressor market size was valued at USD 12.14 billion in 2024. The market is projected to grow from USD 12.71 billion in 2025 to USD 19.51 billion by 2034, exhibiting a CAGR of 4.9 % during 2025–2034.

A screw compressor is a type of gas compressor that uses a rotary positive-displacement mechanism to compress air or gas. Its design relies on two interlocking helical rotors, commonly referred to as the male and female rotors, which rotate within a chamber. Screw compressors come in two main types: oil-injected and oil-free. These compressors are widely used across industries due to their ability to provide a continuous supply of compressed air. The advantages of screw compressors include energy efficiency, reliability, and lower noise levels compared to piston compressors. The ability of screw compressors to operate continuously without significant vibration makes them suitable for large-scale industrial applications such as oil refineries, automotive plants, and medical facilities.

The rising production of motor vehicles across the globe is propelling the screw compressor market growth. European Automobile Manufacturers Association published a report stating that, in 2022, 85.4 million motor vehicles were produced around the world, an increase of 5.7% compared to 2021. Automotive production relies heavily on compressed air for tasks such as painting, assembly, and operating pneumatic tools, and screw compressors provide the efficient, continuous air supply needed for these operations. Additionally, the automotive industry's shift toward automation and precision manufacturing further drives the need for advanced screw compressors that maintain consistent air pressure and reduce downtime.

To Understand More About this Research: Request a Free Sample Report

The screw compressor market demand is driven by increasing mining activities worldwide. Mining activities require reliable and efficient compressed air systems to power various tools and machinery used in mineral exploration, extraction, and processing. Screw compressors, known for their durability and high performance, are essential for operating pneumatic tools, drilling equipment, and ventilation systems in both underground and open-pit mining environments. Additionally, the growing emphasis on energy efficiency and sustainability in the mining industry drives the adoption of screw compressors, as they offer better energy savings and lower maintenance costs compared to traditional compressors. Hence, the demand for screw compressors is rising with the increasing mining activities worldwide.

Screw Compressor Market Dynamics

Growing Urbanization Across the Globe

Rising urbanization drives the construction of new buildings, roads, and utilities, all of which require compressed air for tools and machinery used in construction processes, which screw compressors efficiently provide. The growing urbanization further leads to increased demand for consumer goods and services, which propels manufacturing and industrial sectors that rely on screw compressors for their operations. Additionally, the emphasis on energy efficiency and sustainability in urban development favors screw compressors, as they offer better performance and lower energy consumption compared to traditional compressors. According to data published by the United Nations, more than half of the global population lives in urban areas, up from around one-third in 1950 and projected to increase to around two-thirds in 2050. Therefore, growing urbanization across the globe boosts the screw compressor market development.

Growing Advancement in Technology

Innovations such as oil-free designs, energy-efficient technology, and the integration of control systems for improved management are aligning with the rising push for cleanliness and sustainability, creating opportunities for screw compressor manufacturers. Manufacturers are further integrating smart controls, variable speed drives, and energy-efficient designs into modern screw compressors, making them more appealing to industries seeking cost-effective and reliable solutions. Industries such as automotive, manufacturing, and healthcare are adopting these advanced compressors to improve productivity and reduce operational costs. Thus, as technology evolves, businesses replace outdated equipment with modern screw compressors that offer better energy savings and lower maintenance requirements. Hence, rising technological advancements are expected to offer lucrative screw compressor market opportunities.

Screw Compressor Market Segmental Insights

Screw Compressor Market Evaluation by Type

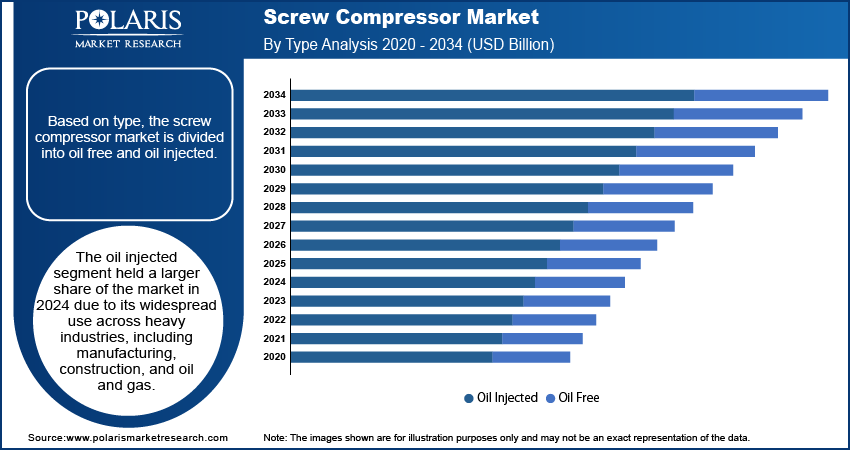

Based on type, the screw compressor market is divided into oil free and oil injected. The oil injected segment held a larger screw compressor market share in 2024 due to its widespread use across heavy industries, including manufacturing, construction, and oil and gas. These compressors deliver high efficiency and durability, making them the preferred choice for applications that demand continuous and reliable operation. Industries rely on them for their ability to handle high-pressure requirements and deliver consistent airflow, which is essential for processes such as metal fabrication, chemical production, and industrial automation. The lower initial cost compared to oil-free alternatives further strengthened their market position, as businesses prioritized cost-effective solutions without compromising performance. Additionally, advancements in lubrication technology, improved energy efficiency, and reduced maintenance costs encouraged the adoption of oil injected screw compressors across various industrial sectors.

Screw Compressor Market Outlook by End User

In terms of end user, the screw compressor market is segregated into oil and gas, food and beverages, energy and power, chemicals and petrochemicals, and others. The food and beverages segment is expected to grow at a robust pace in the coming years, owing to the growing emphasis on hygiene, product quality, and regulatory compliance. The food and beverages sector requires contamination-free and oil-free compressed air for applications such as food packaging, beverage carbonation, and pneumatic conveying of ingredients, which screw compressors provide. Imposition of stringent food safety regulations and increasing consumer demand for high-quality, preservative-free products have driven companies to invest in advanced air compressors, including screw compressors, that eliminate the risk of contamination. Additionally, automation in food processing facilities has expanded, increasing the need for reliable compressed air systems that support precision-based operations. The shift toward sustainable and energy-efficient production methods has also played a key role, encouraging businesses to adopt screw compressors that reduce energy consumption while maintaining high performance and compliance with international food safety standards.

Screw Compressor Market Regional Analysis

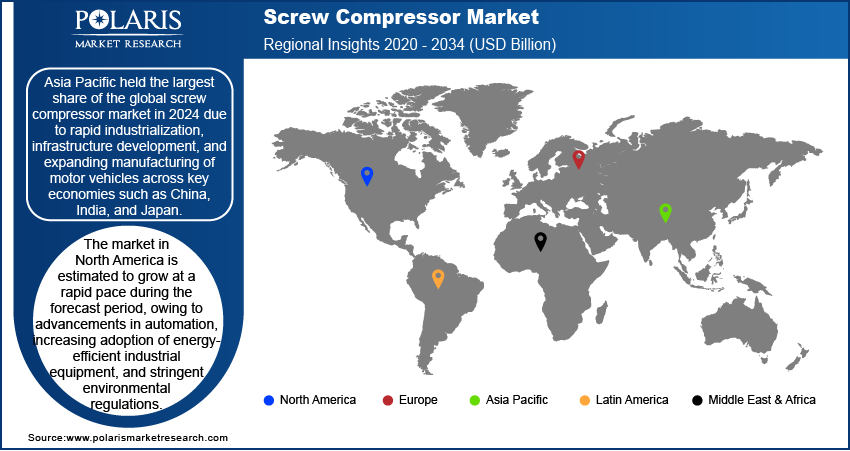

By region, the report provides screw compressor market insight into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific held the largest screw compressor market revenue share in 2024 due to rapid industrialization, infrastructure development, and expanding manufacturing of motor vehicles across key economies such as China, India, and Japan. International Organization of Motor Vehicle Manufacturers published a report stating that India produced a total of 5.46 million motor vehicles in 2022. China dominated the regional market, driven by its massive industrial base, increasing investments in energy and power projects, and government initiatives supporting manufacturing growth. The country’s strong presence in heavy industries, along with its role as a global manufacturing hub, contributed significantly to the screw compressor market expansion. Additionally, rising construction and infrastructure projects across emerging economies boosted the need for screw compressors, ensuring steady market growth in the region.

The North America screw compressor market is estimated to grow at a rapid pace during the forecast period, owing to advancements in automation, increasing adoption of energy-efficient industrial equipment, and stringent environmental regulations. The US is expected to lead this region, supported by its well-established oil and gas industry, strong presence in advanced manufacturing, and rising demand for clean energy solutions. Growth in sectors such as healthcare, pharmaceuticals, and food processing has also contributed to increased adoption of screw compressors, as these industries require contamination-free and high-purity air compression solutions. Furthermore, government incentives promoting energy-efficient industrial equipment and sustainability initiatives have driven businesses to upgrade their systems, thereby boosting demand for screw compressors as these compressors offer better energy savings compared to traditional reciprocating compressors.

Screw Compressor Market – Key Players & Competitive Analysis Report

The screw compressor market is highly competitive, characterized by the presence of numerous global and regional players striving to enhance their market position through technological advancements, strategic partnerships, and expansion initiatives. Companies are focusing on developing energy-efficient and environmentally friendly screw compressors to meet the rising demand across industries such as manufacturing, oil & gas, food & beverage, and healthcare. Innovation in variable-speed drive (VSD) technology and the integration of IoT-enabled predictive maintenance solutions have become key differentiators among competitors. Additionally, the market is witnessing increased investments in research and development to improve compressor efficiency, reduce operational costs, and comply with stringent emission regulations. Competitive pricing, after-sales service, and distribution network expansion play crucial roles in maintaining market share. The growing trend of industrial automation and smart manufacturing is further intensifying competition, compelling market participants to offer advanced, customized solutions to cater to evolving industrial requirements.

The screw compressor market is fragmented, with the presence of numerous global and regional market players. Major players in the market are Atlas Copco AB, BAUER KOMPRESSOREN GmbH, Boge Kompressoren, ELGI EQUIPMENTS LIMITED, Gardner Denver, Ingersoll Rand, Kaeser Kompressoren SE, Kobelco, Quincy Compressor, Sullair, and other.

Elgi Equipments Limited, founded in 1960 by LRG Naidu, is a global manufacturer of air compressors based in Coimbatore, India. The company operates across more than 120 countries and serves industries such as manufacturing, textiles, agriculture, automotive, and construction. It specializes in a wide range of products, including oil-lubricated and oil-free screw compressors, piston compressors, diesel and electric portable compressors, and medical air systems. Elgi's innovative approach is supported by its in-house research and development division, advanced design capabilities, and advanced manufacturing facilities located in India, China, Italy, and France.

Ingersoll Rand Inc., founded in 1859 and headquartered in Davidson, North Carolina, is a global company in diversified industrial solutions. The company specializes in manufacturing air compressors, vacuum and blower systems, fluid management systems, power tools, and lifting equipment. Ingersoll Rand operates through two primary segments: Industrial Technologies and Services (ITS) and Precision and Science Technologies (PST). The company was restructured in 2020 following the merger of Gardner Denver with the industrial segment of Ingersoll-Rand plc, now known as Trane Technologies. Ingersoll Rand employs approximately 21,000 people globally. A key product line for Ingersoll Rand is its screw compressors, which are renowned for their efficiency and durability. The company offers both oil-injected and oil-free screw compressors tailored for diverse industrial applications.

Key Companies in Screw Compressor Market

- Atlas Copco AB

- BAUER KOMPRESSOREN GmbH.

- Boge Kompressoren

- ELGI EQUIPMENTS LIMITED

- Gardner Denver

- Ingersoll Rand

- Kaeser Kompressoren SE

- Kobelco

- Quincy Compressor

- Sullair

Screw Compressor Industry Developments

February 2024: Elgi Equipments launched the PG 550-215 trolley-mounted portable screw compressor at the 12th edition of India Stonemart 2024 at the Jaipur Exhibition and Convention Centre (JECC), Rajasthan, India.

October 2023: CompAir, a global provider of an extensive range of reliable, energy-efficient compressors, dryers, and accessories, announced the launch of its latest RL series, the RL30-160 oil-lubricated screw compressor.

April 2023: Kaishan USA, a worldwide manufacturer of industrial air compressors, introduced a new series of industrial, low-pressure rotary screw air compressors, the KRSL.

Screw Compressor Market Segmentation

By Type Outlook (Revenue, USD Billion, 2020–2034)

- Oil Free

- Oil Injected

By Stage Outlook (Revenue, USD Billion, 2020–2034)

- Single Stage

- Multi Stage

By Technology Outlook (Revenue, USD Billion, 2020–2034)

- Portable

- Stationary

By Power Source Outlook (Revenue, USD Billion, 2020–2034)

- Electric

- Gasoline

By End User Outlook (Revenue, USD Billion, 2020–2034)

- Oil and Gas

- Food and Beverages

- Energy and Power

- Chemicals and Petrochemicals

- Others

By Regional Outlook (Revenue, USD Billion, 2020–2034)

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Screw Compressor Market Report Scope

|

Report Attributes |

Details |

|

Market Value in 2024 |

USD 12.14 Billion |

|

Market Forecast in 2025 |

USD 12.51 Billion |

|

Revenue Forecast by 2034 |

USD 19.51 Billion |

|

CAGR |

4.9% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global screw compressor market size was valued at USD 12.14 billion in 2024 and is projected to grow to USD 19.51 billion by 2034.

The global market is projected to register a CAGR of 4.9% during the forecast period.

Asia Pacific held the largest share of the global market in 2024 due to rapid industrialization, infrastructure development, and expanding manufacturing of motor vehicles across key economies such as China, India, and Japan.

A few of the key players in the market are Atlas Copco AB, BAUER KOMPRESSOREN GmbH, Boge Kompressoren, ELGI EQUIPMENTS LIMITED, Gardner Denver, Ingersoll Rand, Kaeser Kompressoren SE, Kobelco, Quincy Compressor, and Sullair.

The oil injected segment dominated the market in 2024 due to its widespread use across heavy industries, including manufacturing, construction, and oil and gas.

The food and beverages segment is expected to grow at the fastest pace in the coming years owing to the growing emphasis on hygiene, product quality, and regulatory compliance.