Rotary Pumps Market Share, Size, Trends, Industry Analysis Report, By Type (Screw Pump, Gear Pump), By End-use (Chemical, Oil & Gas, Power Generation, Agriculture), By Region, And Segment Forecasts, 2024 - 2032

- Published Date:Jan-2024

- Pages: 116

- Format: PDF

- Report ID: PM4157

- Base Year: 2023

- Historical Data: 2019 – 2022

Report Outlook

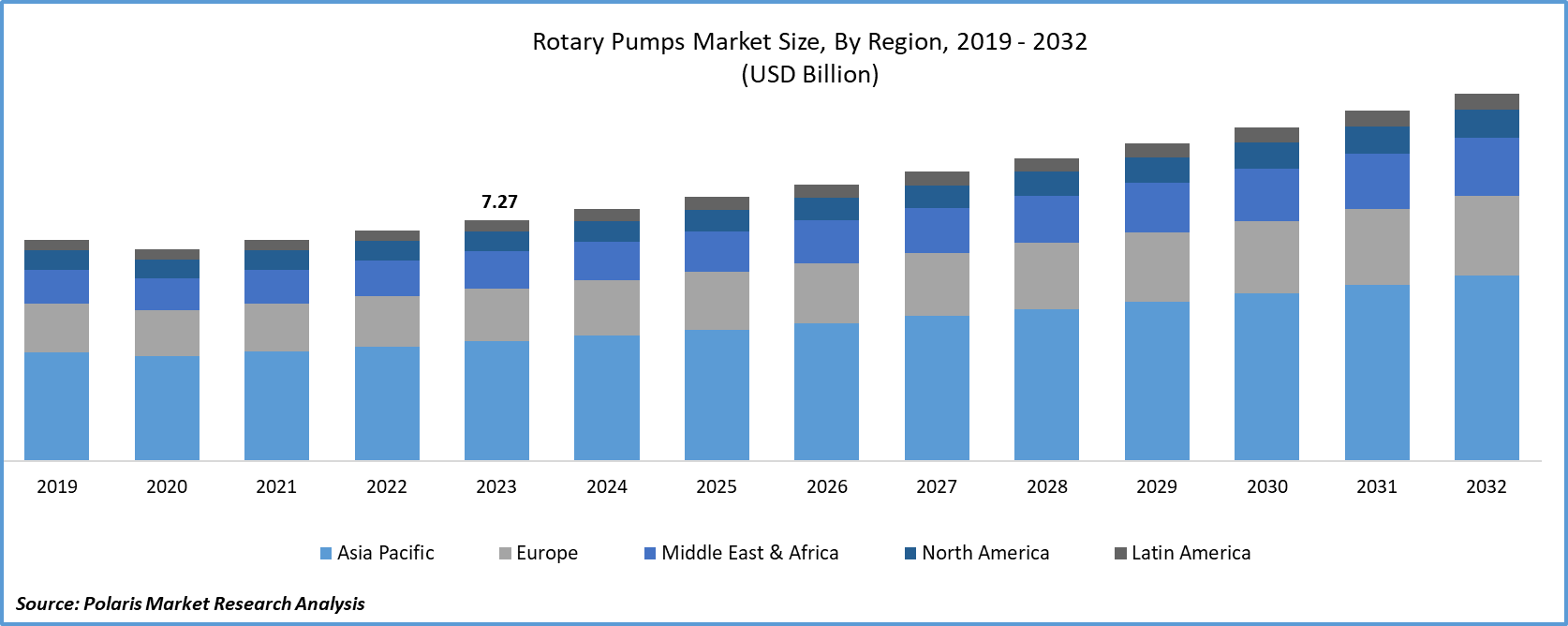

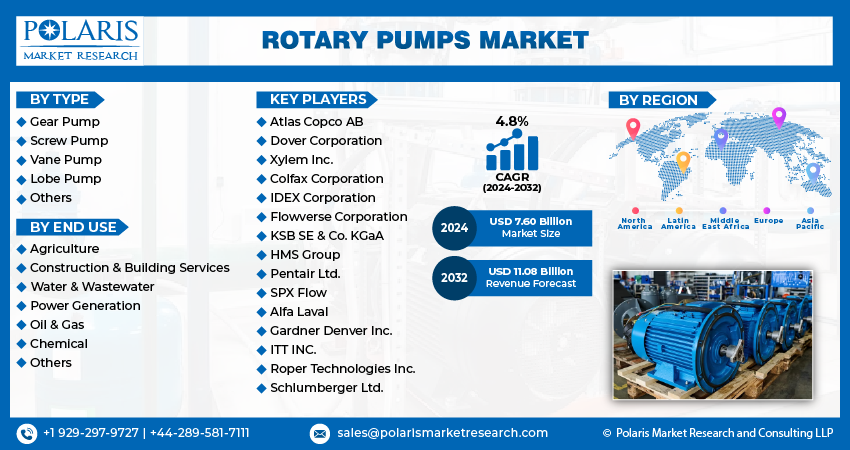

The global rotary pumps market was valued at USD 7.27 billion in 2023 and is expected to grow at a CAGR of 4.8% during the forecast period.

The market is experiencing growth primarily due to the escalating fluid handling requirements in industries like oil & gas, chemicals, & waste-water treatment. Rotary pumps, known for their flexibility in handling fluids with varying viscosities, are becoming increasingly preferable in meeting these diverse requirements. With companies facing heightened pressure to minimize their carbon footprint, there is a growing trend towards strategic investments in environmentally friendly technologies, particularly energy-efficient rotary pumps. These investments have proven successful in reducing both energy consumption and emissions.

To Understand More About this Research: Request a Free Sample Report

To align with sustainable corporate practices and environmental objectives, organizations are placing a higher priority on product usage to enhance the carbon efficiency of their facility operations. In essence, the market growth is fueled by the need for versatile fluid handling solutions, coupled with a strategic shift towards environmentally friendly and energy-efficient technologies to meet sustainability goals in various industries.

Major players in the industry are creating pumps that are not only more energy-efficient but also have a reduced carbon footprint. The newly designed pumps come equipped with variable speed drives (VSDs), enhancing their capabilities, and contributing to the overall market development. Certain sectors, like chemical processing, necessitate specialized rotary pumps capable of handling highly corrosive, viscous, and acidic fluids. As a solution, manufacturers are providing customization options and leveraging their expertise to meet the specific demands of these industries.

Furthermore, as digitalization and the Internet of Things (IoT) become more prevalent, businesses are introducing IoT-based solutions for pumps to augment the capabilities of rotary pumps. The market is characterized by intense competition and a concentration of numerous players with specialized expertise in product design and development. Key industry players are making substantial investments in research and development (R&D) activities, allowing them to not only maintain but also expand their market share, thereby achieving deeper penetration within the industry.

For More Details, Request for Report Discount

Growth Drivers

- Growth in infrastructure projects, such as construction, water treatment, and oil and gas exploration, can boost the demand for rotary pumps

The rotary pumps market is poised for significant growth, driven by the extensive use of rotary pumps in the oil & gas industry for fluid transport within the refining process. Additionally, these pumps play a crucial role in transferring fluids with varying densities in the manufacturing processes, especially as the chemical processing industry experiences an upswing in operations. The dynamic nature of end-use industries, coupled with a growing emphasis on energy efficiency and sustainability, points toward future market trends.

In the oil & gas sector, rotary pumps are essential for the transportation of fluids during the refining process. This critical application contributes to the anticipated growth of the market. Moreover, as the chemical processing industry expands its operations, there is an increased demand for rotary pumps to handle the transfer of fluids with different densities, further boosting market prospects.

Report Segmentation

The market is primarily segmented based on type, end use, and region.

|

By Type |

By End Use |

By Region |

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Type Analysis

- Gear pumps segment held the largest share

Gear pumps segment held the largest share. The fundamental concept behind gear pumps involves capturing and moving fluid by leveraging the spaces formed between the teeth of these rotating gears. These pumps find widespread application across diverse industries, including hydraulic systems, lubrication systems, fuel transfer, and chemical processing. Notably, they are well-suited for handling fluids with varying corrosiveness, viscosity, and density. Renowned for their reliability in maintaining a consistent flow rate, gear pumps are also known for their low maintenance requirements.

Screw pump segment expected to grow at the significant pace. A screw pump, falling under the category of positive displacement rotary pumps, operates by utilizing rotating screws to convey fluid from the input point to the output point. Screw pumps come in different types, such as single screw pumps or multi-screw pumps. Within the oil & gas industry, they play a crucial role in transferring crude oil & refined products during refining processes in refineries.

By End Use Analysis

- Oil & gas segment held the significant market revenue share in 2023

Oil & gas segment held the largest share. Rotary pumps play a crucial role in the oil and gas industry, serving various critical functions owing to their reliability, versatility, and capability to handle a broad spectrum of fluids, including both crude oil and refined products. Additionally, these pumps are employed for the transfer of crude oil from the well-heads to the storage tanks, & for loading and un-loading from tankers & pipelines. Their suitability in managing the diverse viscosities & abrasive characteristics of crude oil is particularly noteworthy. In the oil & gas industry, maintaining a consistent discharge rate is of paramount importance.

The discharge rate of rotary pumps is directly linked to the revolutions per minute (RPMs). By employing suitable control systems, it becomes possible to manage the RPMs and, consequently, uphold both the discharge rates and reliability. Moreover, given the continuous variation in the viscosity of crude oil throughout the refining process, rotary pumps find extensive use in the industry.

Chemical segment will grow at the rapid pace. Rotary pumps are utilized in the chemical industry because of their capacity to manage an extensive variety of chemical substances, encompassing corrosive and viscous liquids. Gear and screw pumps play a vital role in transferring diverse chemicals between containers or vessels, ensuring precise and regulated flow rates. The quality of chemical processing often hinges on the accurate metering of chemicals to enhance product quality by controlling process variables like discharge rates and fluid pressure. Rotary pumps, given their ease of control over these variables, are frequently employed in mixing chemicals and creating blends for various manufacturing processes, including cosmetics.

Regional Insights

- Asia Pacific region held the largest share of the global market in 2023

APAC dominated the market. The adoption of the product has been facilitated by rapid industrialization and the increasing need for fluid handling in various countries. Pumps play a crucial role as essential inputs in the agriculture sector, as ensuring a sufficient water supply to watershed areas is impractical without their utilization. Additionally, numerous countries in the region are anticipated to experience growth, thanks to the heightened investments by governments in the agriculture, power generation, & the construction sectors.

MEA projected to grow at the rapid pace. This is primarily due to the well-established oil & gas and power generation industries. This region serves as a significant hub for oil & gas production, where rotary pumps play a crucial role in the transfer and refining processes of crude oil. Additionally, there is substantial investment in the construction of facilities in Middle Eastern countries to generate potable water from saline sources, with rotary pumps being employed in water treatment plants for water transfer purposes.

Key Market Players & Competitive Insights

Manufacturers employ a range of strategies, such as acquisitions, mergers, joint ventures, advancements in new materials, and geographical expansions, to augment market penetration and address the evolving needs of diverse end-use industries. Several major companies have taken initiatives like technological upgrades and increased investments in research and development activities to establish a stronger foothold in the market.

Some of the major players operating in the global market include:

- Atlas Copco AB

- Dover Corporation

- Xylem Inc.

- Colfax Corporation

- IDEX Corporation

- Flowverse Corporation

- KSB SE & Co. KGaA

- HMS Group

- Pentair Ltd.

- SPX Flow

- Alfa Laval

- Gardner Denver Inc.

- ITT INC.

- Roper Technologies Inc.

- Schlumberger Ltd.

Recent Developments

- In October 2022, Atlas Copco has broadened its range of rotary pumps by launching the DVS Series. This product had with features like being oil-free, generating low noise, and preventing contamination of the process.

Rotary Pumps Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 7.60 billion |

|

Revenue forecast in 2032 |

USD 11.08 billion |

|

CAGR |

4.8% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Type, By End Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

FAQ's

The rotary pumps market report covering key segments are type, end use, and region.

Rotary Pumps Market Size Worth $11.08 Billion By 2032

The global rotary pumps market is expected to grow at a CAGR of 4.8% during the forecast period.

Asia Pacific is leading the global market

key driving factors in rotary pumps market are Growth in infrastructure projects, such as construction, water treatment, and oil and gas exploration, can boost the demand for rotary pumps