Rare Earth Metal Recycling Market Share, Size, Trends, Industry Analysis Report, By Application (Permanent Magnets, Alloys, Polishing Materials, Glass, Catalyst, Phosphor, Ceramics, Hydrogen Storage Alloys), By Technology; By Region; Segment Forecast, 2022-2030

- Published Date:Dec-2022

- Pages: 118

- Format: PDF

- Report ID: PM2881

- Base Year: 2021

- Historical Data: 2018-2020

Report Outlook

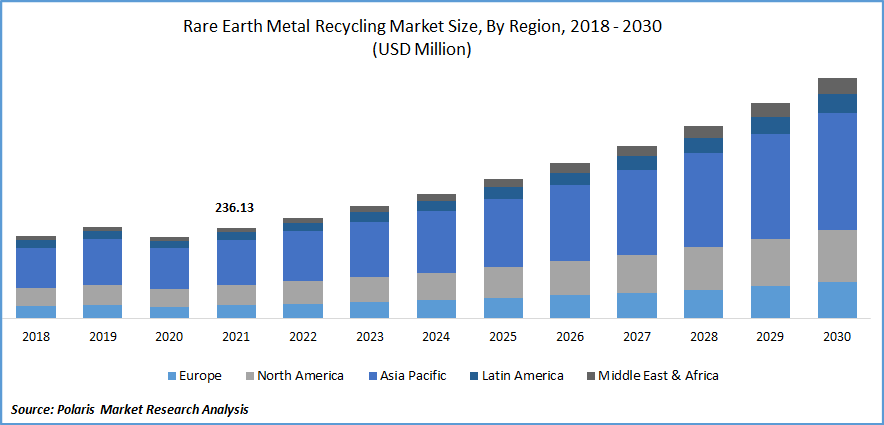

The rare earth metal recycling market was valued at USD 236.13 million in 2021 and is expected to grow at a CAGR of 11.4% during the forecast period.

Rare earth metals are important for emerging technologies in the military, electronics, automotive, and communications industries. These substances are essential to the development of new applications like green technology and electric and hybrid cars, and the demand for these substances is driving the market.

Know more about this report: Request for sample pages

In a wide range of consumer goods, including electronics and automobiles, rare earth elements are essential components. Only a dozen of the almost 200 minerals have high concentrations of RE metals to be economically extractable. Due to their special chemical, magnetic, electrical, and luminescence properties, Rare Earth (RE) metals are essential for advanced technology like computers and MRIs.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The need to develop and use technologies for recycling rare earth elements is being driven by the steps taken worldwide to move to a cleaner and greener environment. The transition to using more of the sun, wind, tidal, and electricity generated naturally is being accelerated. And a variety of technologies that provide cleaner, greener energy employ rare earth elements. The abundant usage of RE for a sustainable environment is expected to drive the growth of the market.

Rare earth metal extraction and mining harm the ecosystem and environment. They are extracted utilizing incredibly energy-intensive procedures that release pollutants into the ground and carbon emissions into the atmosphere. Mercury, barium, lead, chromium, and cadmium are only a few of the metals that are particularly harmful to the health of various ecosystems, including humans. Rare earth extraction can be risky and challenging when these ores contain other radioactive elements like uranium or thorium.

The resources are therefore expected to run out and exhaust as demand and exploitation increase, making the extraction of these elements unprofitable. Recycling is therefore required to satisfy the demand for RE metals. Furthermore, some applications, including florescent lamps and rare earth magnets, contain considerably larger concentrations of rare earth elements and are therefore more cost-effective and recyclable. This drives the growth of the global market.

Governments are emphasizing the green environment; therefore, legislation is banning the use of conventional materials in industries to obtain a sustainable environment. They need to use green technologies like wind turbines, compact fluorescent lighting, and HE vehicles. Wind turbines are now using direct drive permanent magnets which have a major quantity of rare earth metals such as neodymium, europium, praseodymium, dysprosium, and terbium. The need to protect the environment results in the development of clean energy resources like wind energy. Wind turbines and water turbines use permanent magnets, increasing growth opportunities for the market. Direct drive generators for wind turbines need permanent magnets for power output. This shows that the use of permanent magnets is economical and helps the environment to become greener and cleaner. All these factors increase the growth of the global market.

Report Segmentation

The market is primarily segmented based on application, technology, and region.

|

By Application |

By Technology |

By Region |

|

|

|

Know more about this report: Request for sample pages

Glass segment is expected to dominate the market

The three rare earth elements that are most frequently utilized in glass are erbium, ytterbium, & neodymium. Erbium mixed silica is used for optical communication, ytterbium mixed silica is used in engineering materials, & neodymium-doped glass lasers are utilized for inertial confinement fusion.

In the glass industry, rare earth is utilized as a clarifier, decolorizer, colorant, & polishing powder. It is possible to create optical glass, which may be used to create high-quality lenses for cameras, telescopes, and other high-quality optical instruments, by utilizing the properties of some rare earth elements, such as high refraction and low dispersion. Thus, rare earth metals are utilized in many ways therefore the market is dominating globally. The permanent magnet market is expected to grow at the fastest rate. The permanent magnets are extracted from neodymium, praseodymium, and dysprosium. The wind turbines and automobile sector are the biggest users of permanent magnets.

The hydrometallurgical technology segment is to witness higher CAGR during the forecast period

In hydrometallurgy technology, three steps must be considered to extract rare earth metals. Rare earth component dissolves in acid, occasionally under high pressure and temperature. And then extraction is done using a solvent or using an ionic liquid and ion exchange to separate the various REE into pure and concentrated solutions. And lastly, pure and unique earth metals are produced. This technology recovers rare earth metals from secondary wastes such as spent magnets, batteries, e-wastes, and others.

The pyrometallurgical process extracts 99% of rare earth metals from batteries and magnets. The rare earth metals are obtained from high-temperature treatment which gives 96% of rare earth metals by weight. Hydrometallurgical technology has many advantages as compared to the pyrometallurgical technique. The advantages are a small amount of waste generation, low production costs, and low levels of noxious gases emission. Hydrometallurgical technology gives clean rare earth metals which prevent the degradation of the environment.

Asia Pacific is expected to hold the largest market share

Asia Pacific has experienced enormous growth in recent years due to investment policies, expanding population, expanding economies, and government initiatives to support the electronics and automobile industries. REEs, such as neodymium, yttrium, and terbium, are important materials mostly present in wind turbines, smartphones, and electric vehicles. Today, China produces 80% of rare earth elements. Due to China's rapidly rising demand, which accounts for the majority of rare earth metal consumption worldwide, the area is the greatest user of rare earth elements.

Competitive Insights

Key players in the market include Solvay, Hitachi Metals, Umicore, OSRAM Licht, Energy Fuels, American Rare Earth, Arafura Resources, Jingui Silver Industry, Geomega Resources, Urban Mining, and Mitsubishi Electric.

Recent Developments

In Sept. 2022, Solvay announced intentions to expand its operations, in France to enter the European market & better serve clients in the rapidly expanding markets for electric vehicles, wind power, and electronics.

In Dec. 2021, Umicore & Volkswagen formed a joint venture to develop precursor & cathode material production units, in Europe. This joint venture significantly aided the region's transition to greener mobility.

Rare Earth Metal Recycling Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2022 |

USD 262.46 million |

|

Revenue forecast in 2030 |

USD 623.39 million |

|

CAGR |

11.4% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD million and CAGR from 2022 to 2030 |

|

Segments covered |

By Application, By Technology, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key companies |

Solvay SA, Hitachi Metals, Umicore, OSRAM Licht AG, Energy Fuels, American Rare Earth LLC, Arafura Resources, Chenzhou City Jingui Silver Industry, Geomega Resources, Urban Mining Company, Mitsubishi Electric Corporation |