Metal Stamping Market Share, Size, Trends, Industry Analysis Report, By Process (Blanking, Embossing, Bending, Coining, Flanging, Others); By Press Type; By Thickness; By Application; By Region; And Segment Forecasts, 2024 - 2032

- Published Date:Jan-2024

- Pages: 119

- Format: PDF

- Report ID: PM4192

- Base Year: 2023

- Historical Data: 2019 – 2022

Report Outlook

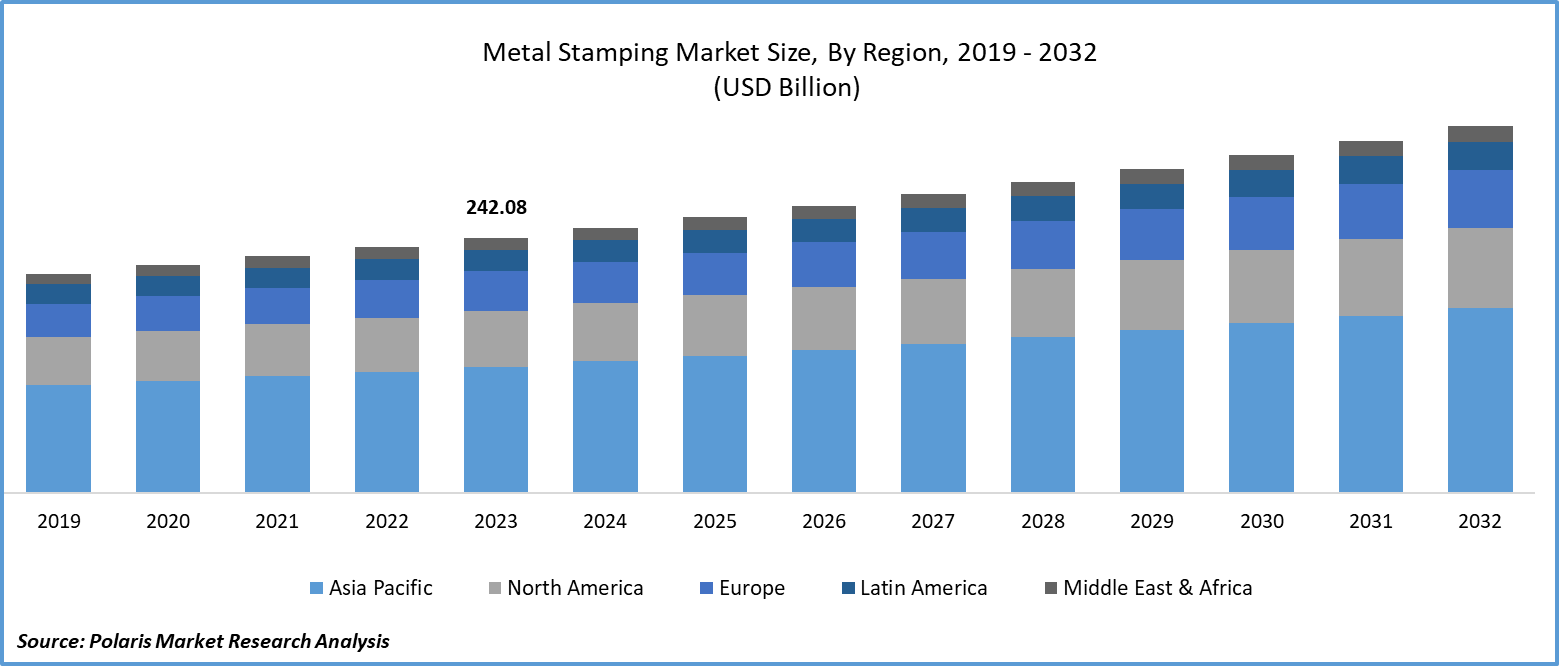

The global metal stamping market was valued at USD 242.08 billion in 2023 and is expected to grow at a CAGR of 4.1% during the forecast period.

The continuous growth of the consumer electronics industry is expected to be a significant driving factor, particularly with the widespread application of metal frames in various devices such as mobile phones, headphones, speakers, gamepads, & controllers. In the manufacturing of mobile phones, metal stamping plays a crucial role in producing components like antennas, chassis, & camera holders. This is attributed to the advantages it offers, including high tolerance, electrical conductivity, & smooth finish. According to the GSM Association, as of January 2021, the global number of new mobile subscribers reached 5.3 Bn, with a yearly growth rate of 1.8%. This continuous increase in mobile subscribers is expected to fuel the demand for mobile phones, consequently driving the demand for metal stamping in the years to come.

To Understand More About this Research: Request a Free Sample Report

The onset of the COVID-19 pandemic and subsequent temporary nationwide lockdowns significantly affected the operations of the industry. Disruptions in the supply chain and diminished demand from end-use customers, particularly in key sectors like automotive, aerospace, and industrial machinery, were observed. As the vaccination rate has accelerated, the situation has gradually normalized. The increasing demand for metal stamping in the U.S. has prompted manufacturers to undertake facility expansions.

The research study provides a comprehensive analysis of the industry, assessing the market on the basis of various segments and sub-segments. It sheds light on the competitive landscape and introduces Metal Stamping Market key players from the perspective of market share, concentration ratio, etc. The study is a vital resource for understanding the growth drivers, opportunities, and challenges in the industry.

The rising production of lightweight vehicles, driven by stringent government regulations in multiple countries, is expected to fuel the demand for alternative products. Notably, in the U.S., advancements in Corporate Average Fuel Economy (CAFE) regulations aimed at improving fuel efficiency are promoting the adoption of these alternative products in automobiles. Consequently, this trend is likely to impede the market for metal stamping.

Growth Drivers

- Rising automotive manufacturing drives robust growth in the metal stamping market

In 2021, global electric vehicle (EV) sales exceeded 3.4 million units, with China contributing to over 50% of this figure, as reported by the International Energy Agency (IEA). Government initiatives, including subsidies for electric cars provided to local manufacturers to foster the growth of EVs, have played a significant role in driving increased production. This surge in electric vehicle manufacturing is expected to lead to a heightened demand for sheet metal in the production of various auto components.

These components encompass chassis, interior and exterior structural elements, as well as transmission components. This is anticipated to stimulate metal stamping market growth throughout the forecast period. However, the growth trajectory may face obstacles as automotive manufacturers increasingly substitute metals with materials like plastic and carbon fiber to achieve vehicle weight reduction. It is noteworthy that a 10% reduction in vehicle weight leads to a corresponding 5% to 7% enhancement in fuel efficiency.

Report Segmentation

The market is primarily segmented based on process, press type, thickness, application, and region.

|

By Process |

By Press Type |

By Thickness |

By Application |

By Region |

|

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Process Analysis

- Blanking segment held the largest share of the market in 2023

The blanking segment held the largest share. Blanking plays a crucial role in automobile manufacturing due to its precise and superior stamping capabilities. This method utilizes a die to achieve the desired shape. The increasing adoption of blanking in the automobile industry, particularly for mass production lines, is anticipated to contribute significantly to the growth of this segment in the years to come.

The bending segment is projected to grow at the fastest rate. The bending process involves applying pressure to shape metal onto a flat surface to achieve the desired form. This method proves to be cost-effective, especially when applied to lower or moderate quantities of metals. Bent components find applications in various uses within automobiles, including wheels, door hinges, and engine assembly.

By Press Type Analysis

- Mechanical press segment registered the largest market share in 2023

The mechanical press segment accounted for the largest share. Mechanical presses are commonly employed in sheet metal processing, known for their rapid and uninterrupted application of pressure over a confined distance. In contrast to hydraulic press machines, mechanical press machines demonstrate higher speeds and are particularly suitable for stamping applications.

The Servo press segment will grow rapidly. It is gaining increased recognition in the market, particularly in the metalworking industry, for precision metal forming processes such as stamping. By incorporating servo motors and controllers, the press rams can be more precisely controlled, leading to enhanced accuracy and flexibility in stamping operations. This represents an advancement over traditional mechanical or hydraulic presses.

By Application Analysis

- Automotive segment held the significant market revenue share in 2023

The automotive segment held the largest share. Various sectors within the automotive industry, encompassing passenger vehicles, light commercial vehicles (LCVs), heavy trucks, buses, and coaches, utilize metal stamping parts in the production of body panels to uphold safety standards and manage overall costs. According to the International Organization of Motor Vehicle Manufacturers, global vehicle production witnessed a 6% increase in 2022 compared to 2021. The anticipated growth in high-volume production is expected to drive the expansion of the metal stamping market in automotive applications in the years to come.

The aerospace segment will grow at a substantial pace. Within the aerospace industry, metal stamping plays a crucial role in manufacturing aircraft components like channels and frames. This application aims to achieve the construction of ultra-lightweight airplanes, contributing to reduced fuel consumption. The utilization of metal stamping in the manufacturing of aircraft parts offers a cost-effective and durable solution, contributing to an anticipated increase in demand. Furthermore, the increasing production of both commercial and fighter aircraft is expected to be a driving force for market growth in the foreseeable future.

Regional Insights

- Asia Pacific held the largest share of the global market in 2023

Asia Pacific dominated the market. The growth is significantly propelled by developing countries, where there is an increasing demand for phones and other consumer electronics, contributing to market expansion. The positive impact on machinery and equipment demand in the region is expected to be driven by growing industrialization, infrastructure development, and expansion in the defense industry.

Countries like China & India are significantly boosting their investments in the defense industry. For instance, China witnessed a notable 41% increase in its defense budget from 2021 to 2022, reaching USD 292 billion. The heightened demand for defense equipment is expected to be a driving force for the market of stamped products in the foreseeable future. India also emerges as a lucrative market for metal stamping, with the anticipated growth in component production expected to have a positive impact on market expansion.

Europe region is projected to grow at a rapid pace. This is primarily attributed to its well-established automotive industry and the burgeoning consumer electronics sector. The region, known for its stringent regulations aimed at improving fuel economy, is experiencing an increased demand for electric vehicles (EVs). According to the International Energy Agency (IEA), the global sales of EVs are projected to reach 44 million vehicles annually by 2030. The growing demand for electric vehicles is expected to contribute to market growth in the upcoming years significantly.

Key Market Players & Competitive Insights

Local players engage in competition with global companies by offering services and tailored products. These local entities have the flexibility to provide personalized customization services to their clients. Simultaneously, they possess the capability to deliver standardized products to major industrial machinery producers, automotive OEMs, and manufacturers in the consumer electronics sector.

Some of the major players operating in the global market include:

- AAPICO Hitech Public Company Limited

- Acro Metal Stamping

- CAPARO

- Clow Stamping Company

- D&H Industries, Inc.

- Ford Motor Company

- Gestamp

- Goshen Stamping Company

- Interplex Holdings Pte. Ltd.

- Kenmode, Inc.

- Klesk Metal Stamping Co

- Manor Tool & Manufacturing Company

- Nissan Motor Co., Ltd

- Tempco Manufacturing Company, Inc

Metal Stamping Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 251.64 billion |

|

Revenue forecast in 2032 |

USD 347.85 billion |

|

CAGR |

4.1% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Process, By Press Type, By Thickness, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

Gain profound insights into the 2024. Metal Stamping Market with meticulously compiled statistics on market share, size, and revenue growth rate by Polaris Market Research Industry Reports. This thorough analysis not only provides a glimpse into historical trends but also unfolds a roadmap with a market forecast extending to 2032. Immerse yourself in the comprehensive nature of this industry analysis through a complimentary PDF download of the sample report.

Browse Our Top Selling Reports

Biogas Market Size, Share 2024 Research Report

Microgrid Market Size, Share 2024 Research Report

Ergonomic Chair Market Size, Share 2024 Research Report

Higher Education Technology Market Size, Share 2024 Research Report

Pet Herbal Supplements Market Size, Share 2024 Research Report

FAQ's

The metal stamping market report covering key segments are process, press type, thickness, application, and region.

Metal Stamping Market Size Worth $347.85 Billion By 2032

The global metal stamping market is expected to grow at a CAGR of 4.1% during the forecast period.

Asia Pacific is leading the global market

key driving factors in metal stamping market are rising automotive manufacturing drives robust growth in the metal stamping market