Laser Processing Market Share, Size, Trends, Industry Analysis Report, By Laser Type (Solid Lasers, Liquid Lasers, Gas Lasers, And Other Types); By Discrete Industry; By Application; By Vertical; By Region.; Segment Forecast, 2024- 2032

- Published Date:Mar-2024

- Pages: 115

- Format: PDF

- Report ID: PM4717

- Base Year: 2023

- Historical Data: 2019 – 2022

Report Outlook

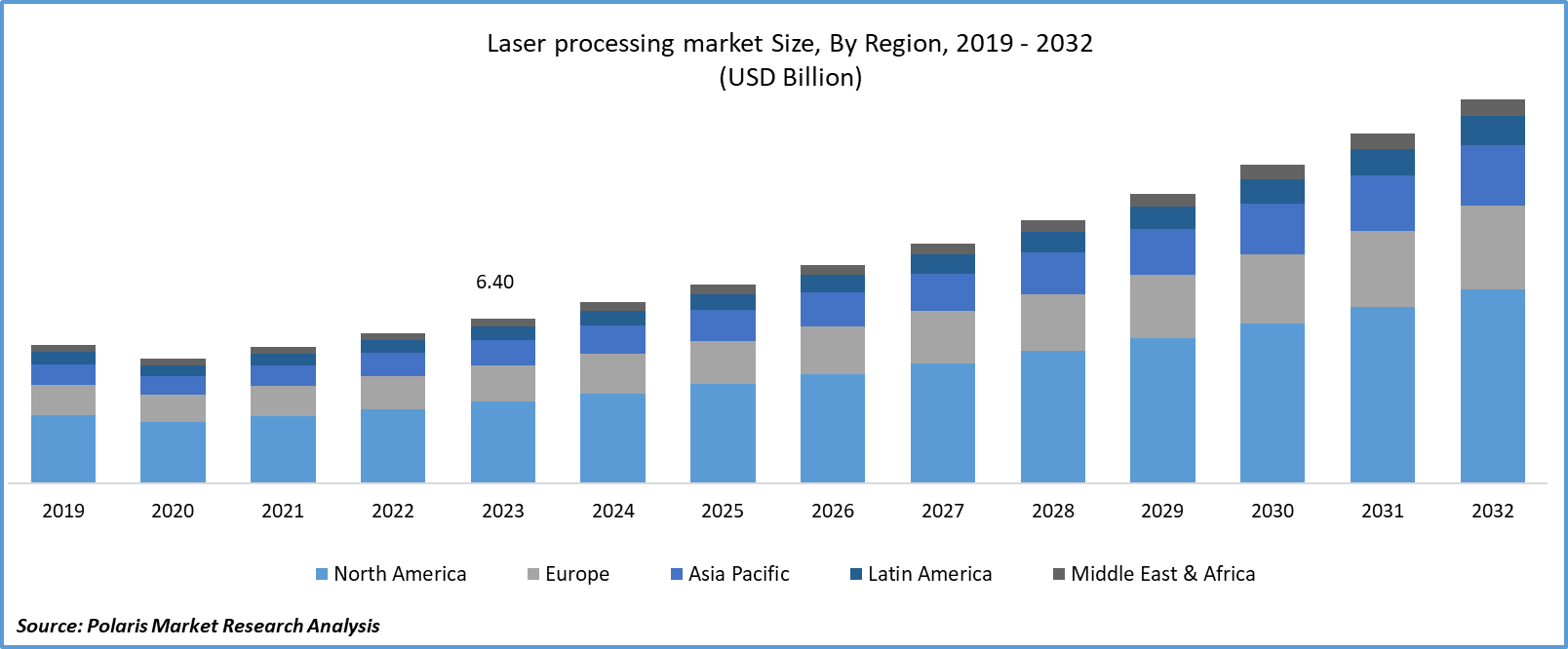

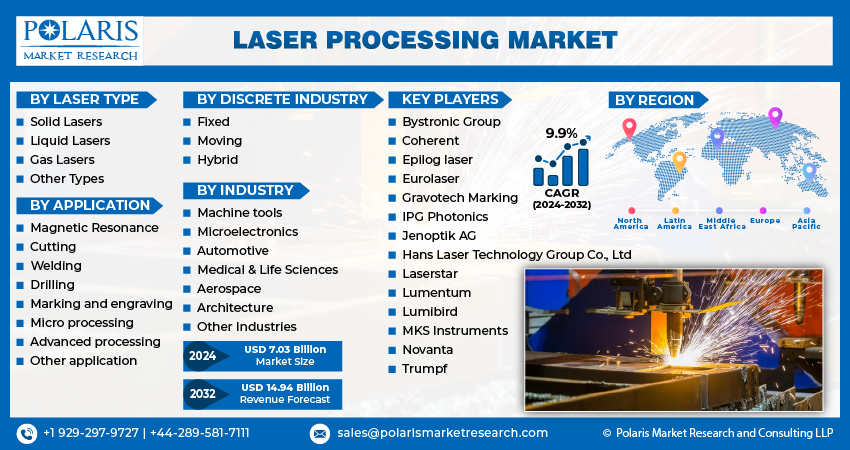

Global laser processing market size was valued at USD 6.40 billion in 2023. The market is anticipated to grow from USD 7.03 billion in 2024 to USD 14.94 billion by 2032, exhibiting a CAGR of 9.9% during the forecast period.

Industry Trend

Laser processing encompasses the utilization of lasers (Light Amplification by Stimulated Emission of Radiation) for various material processing tasks. These lasers emit highly focused beams of light carrying significant energy, making them ideal for precision operations. Laser technology finds diverse applications, including measurement, cutting, drilling, welding, forensic analysis, medical procedures such as plaque removal from arteries and eye surgeries, and communication and data transmission tasks.

The market for laser processing is experiencing substantial growth, primarily driven by increased adoption in medical devices and surgical procedures. Additionally, the rapid advancement of nano-fabrication technology is expected to propel market expansion further. The manufacturing sector increasingly embraces laser technology due to its numerous advantages over traditional processing methods, contributing significantly to market growth.

To Understand More About this Research: Request a Free Sample Report

Key laser processing applications include element detection, laser metrology, fabrication, machining, and medical imaging. Favorable government regulations regarding the use of laser technology in product marking and engraving are anticipated to influence market growth in the forecast period positively.

The company has made significant investments in collaborative and innovative initiatives to transform its operations. Embracing a comprehensive strategy aimed at expanding its market presence, reaching new demographics, and fostering sustainable growth in a dynamic business environment, the company is on the verge of achieving success. Through the synergistic utilization of investment, innovation, technology, and strategic vision, it is well-positioned to maintain competitiveness and emerge as a frontrunner in its sector.

- For instance, In November 2023, IPG Photonics partnered with Miller Electronics Mfg. LLC to drive innovation alongside a dedication to quality and reliability. This collaboration aims to propel laser technologies within the handheld welding sector, revolutionizing the landscape of welding tools. The goal is to offer welders robust, efficient, and accurate solutions tailored to the needs of contemporary welding practices. By combining their expertise, this alliance will introduce dependable solutions that welders can trust for their essential tasks.

Given its versatility across various industries, including welding, cutting, marking, drilling, and engraving, laser processing is poised for substantial growth in the coming years, reflecting its widespread adoption and increasing demand for precision and efficiency in material processing tasks. As a result, laser processing market share is expected to show growth in the upcoming years.

Key Takeaway

- Asia Pacific accounted for the largest market and contributed to more than 38% of the share in 2023.

- North America expected to witness the fastest growing CAGR during the forecast period.

- By laser type category, the solid lasers segment accounted for the largest market share in 2023.

- By the discrete industry category, the hybrid segment is expected to witness the fastest CAGR during the projected period.

What are the market drivers driving the demand for the Laser Processing Market?

Growing application of laser in medical surgeries and devices

The growing application of lasers in medical surgeries and devices serves as a significant driver for the laser processing market. As lasers become increasingly integrated into various medical procedures and equipment, the demand for advanced laser processing technologies rises in tandem. Laser technology offers several advantages in the medical field, including precision, minimally invasive procedures, reduced recovery times, and improved patient outcomes. As a result, healthcare providers and medical device manufacturers are increasingly incorporating lasers into their practices and products.

This growing adoption of lasers in medical applications necessitates advancements in laser processing techniques to meet the specific requirements of medical device manufacturing and surgical procedures. Thus, manufacturers of laser processing equipment are driven to innovate and develop solutions tailored to the unique needs of the medical industry.

Furthermore, the expanding scope of medical applications for lasers, ranging from dermatology and ophthalmology to cardiovascular and oncological procedures, contributes to the sustained growth of the laser processing market. This trend is expected to continue as medical professionals and patients alike recognize the benefits of laser technology in improving healthcare outcomes.

Which factor is restraining the demand for Laser Processing?

The high initial cost involved in laser processing machines is expected to hamper the global laser processing market growth.

The high initial cost associated with laser processing machines is anticipated to hinder the growth of the global laser processing market. This cost encompasses the expenses incurred in acquiring, installing, and maintaining laser processing equipment, including the machinery itself and any necessary supporting infrastructure. For many businesses, particularly small and medium-sized enterprises (SMEs), the substantial upfront investment required for laser processing machines may act as a barrier to adoption. Additionally, the cost of training personnel to operate these sophisticated machines adds to the initial financial burden. As a result, organizations may be reluctant to invest in laser processing technology, especially if they cannot immediately justify the expense or if alternative, less expensive manufacturing methods are available. This high initial cost may, therefore impede the widespread adoption of laser processing solutions, ultimately limiting the overall growth potential of the market.

Report Segmentation

The market is primarily segmented based on laser type, discrete industry, application, industry, and region.

|

By Laser Type |

By Discrete Industry |

By Application |

By Industry |

By Region |

|

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

Category Wise Insights

By Laser Type Insights

Based on Laser type analysis, the market is segmented into solid lasers, liquid lasers, gas lasers, and other types. Solid Lasers held the largest market share in 2023. Significant technological advancements have propelled solid-state lasers to the forefront, enhancing their efficiency, reliability, and cost-effectiveness in comparison to alternative laser types. These developments have resulted in their widespread adoption across diverse industries such as automotive, aerospace, electronics, medical, and materials processing. Solid-state lasers stand out due to their versatility in processing various materials, including metals, plastics, ceramics, and semiconductors. Their capability to deliver high power output and unparalleled precision renders solid-state lasers ideal for a myriad of demanding industrial tasks, ranging from cutting and welding to marking, engraving, and micromachining. Moreover, the cost-effectiveness has expanded their accessibility to a broader spectrum of businesses, thereby reinforcing their dominance in the market.

Renowned for their robustness, reliability, and extended operational lifespans, solid-state lasers are particularly favored in industrial settings where continuous operation and minimal downtime are imperative. This reputation for durability and performance further solidifies their appeal.

By Discrete Industry Insights

Based on discrete industry analysis, the market has been segmented based on fixed, moving, and hybrid. The hybrid segment is expected to witness the fastest-growing CAGR during the forecast period. Hybrid laser processing merges the strengths of various laser technologies like fiber, CO2, and solid-state lasers alongside complementary methods such as milling or waterjet cutting. This adaptability expands the scope of applications and enables the addressing of intricate manufacturing demands. They fine-tune processing parameters for specific materials and tasks, resulting in accelerated production rates and streamlined cycle times.

Precision is a hallmark of hybrid laser systems, granting meticulous control over material manipulation and refinement. This level of accuracy proves invaluable in industries necessitating intricate designs or stringent tolerances, notably aerospace, medical device manufacturing, and electronics sectors. Moreover, the amalgamation of different laser sources in hybrid configurations broadens the spectrum of processable materials. Metals, plastics, composites, ceramics, and even delicate substances like textiles or organic substrates find compatibility with these versatile systems, catering to the varied needs of industries seeking adaptable manufacturing solutions.

Regional Insights

Asia Pacific

Asia Pacific accounted for the largest market share in 2023. The Asia Pacific region hosts some of the globe's most substantial manufacturing economies, encompassing nations like China, Japan, South Korea, and Taiwan. These countries boast extensive industrial infrastructures spanning diverse sectors such as automotive, electronics, aerospace, and healthcare.

Experiencing rapid industrialization and urbanization, the region is witnessing a surge in demand for advanced manufacturing technologies, including laser processing. Industries are incessantly seeking avenues to augment productivity, efficiency, and quality to sustain competitiveness on a global scale. Asia Pacific has emerged as a leader in technological advancements within the laser processing domain. Nations like Japan and South Korea, renowned for their prowess in innovation and technology, particularly excel in industries such as electronics, semiconductors, and automotive manufacturing. The burgeoning automotive, electronics, medical device, and aerospace sectors in the region are pivotal consumers of laser processing technologies. These industries rely on laser systems for a plethora of applications, including cutting, welding, marking, engraving, and micromachining, thereby propelling the demand for laser processing equipment. Governments across the Asia Pacific region are proactively supporting the advancement of cutting-edge manufacturing technologies through various initiatives, incentives, and investments in research and development. These concerted efforts have cultivated an environment conducive to the widespread adoption and progression of laser processing technologies.

North America

North America region is expected to grow at the fastest CAGR during the forecast period. North America stands out for its track record of innovation and technological progress spanning multiple industries. In the laser processing sector, a continuous stream of innovations in laser technologies, automation, and seamless integration with other manufacturing processes is anticipated to be the primary driver of growth. Companies in the region lead the charge in developing state-of-the-art laser systems and solutions meticulously tailored to meet the evolving demands of key sectors like automotive, aerospace, healthcare, and electronics. Industries across North America are progressively embracing advanced manufacturing technologies, including laser processing, as a means to bolster productivity, efficiency, and overall quality standards. Laser systems find widespread application in diverse tasks such as cutting, welding, marking, engraving, and surface treatment, catering to the unique needs of various sectors. The escalating demand for precision manufacturing and bespoke solutions further propels the adoption of laser processing technologies across the region.

With a robust industrial foundation, particularly in pivotal sectors like automotive, aerospace, defense, medical devices, and electronics, North America emerges as a fertile ground for high-precision manufacturing solutions, making it a prime market for laser processing technologies.

Competitive Landscape

The laser processing market is characterized by fragmentation, featuring competition from numerous players. Major service providers in this sector consistently upgrade their technologies to retain a competitive advantage, prioritizing efficiency, reliability, and safety. In pursuit of a significant market share, these entities underscore the importance of strategic partnerships, continuous product improvements, and collaborative initiatives to outperform industry peers.

Some of the major players operating in the global market include:

- Bystronic Group

- Coherent

- Epilog laser

- Eurolaser

- Gravotech Marking

- Hans Laser Technology Group Co., Ltd

- IPG Photonics

- Jenoptik AG

- Laserstar

- Lumentum

- Lumibird

- MKS Instruments

- Novanta

- Trumpf

Recent Developments

- In January 2024, Coherent disclosed the OBIS 640 XT, a red laser module designed to complement its existing portfolio of blue and green laser modules. This new addition boasts low noise, heightened output power, a compact size, and excellent beam quality. When combined with Coherent's blue and green laser modules, the OBIS 640 XT forms a comprehensive set ideal for high-performance SRM (Single Resonator Module) systems.

Report Coverage

The Laser Processing Market report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, laser type, discrete industry, application, industry, and their futuristic growth opportunities.

Laser Processing Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 7.03 Billion |

|

Revenue forecast in 2032 |

USD 14.94 billion |

|

CAGR |

9.9% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Laser Type, By Discrete Industry, By Application, By Industry, And By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region and segmentation. |

FAQ's

The Laser Processing Market report covering key segments are laser type, discrete industry, application, industry, and region.

Laser Processing Market Size Worth $14.94 Billion By 2032

Laser processing market exhibiting a CAGR of 9.9% during the forecast period.

North America is leading the global market

key driving factors in Laser Processing Market are growing application of laser in medical surgeries and devices