India Aerospace & Defense Chemical Surface Treatment Market Share, Size, Trends, Industry Analysis Report, By Type (Cleaners, Plating Chemicals, Conversion Coatings, Others); By Material; Segment Forecast, 2024 - 2032

- Published Date:Apr-2024

- Pages: 116

- Format: PDF

- Report ID: PM4874

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

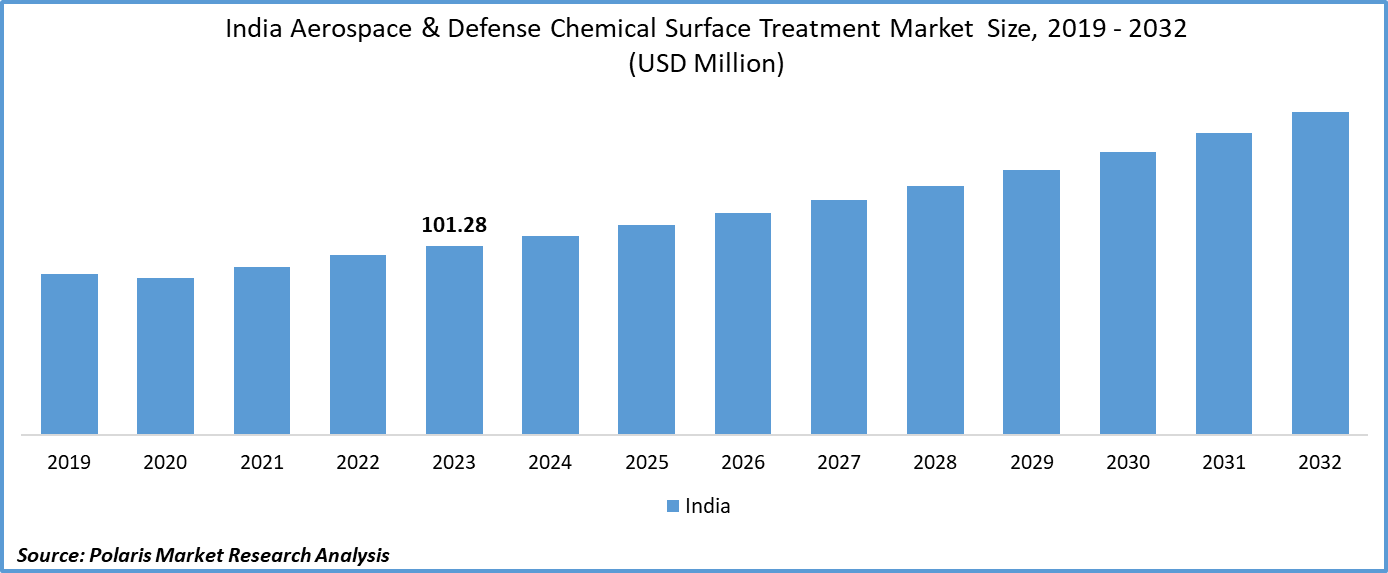

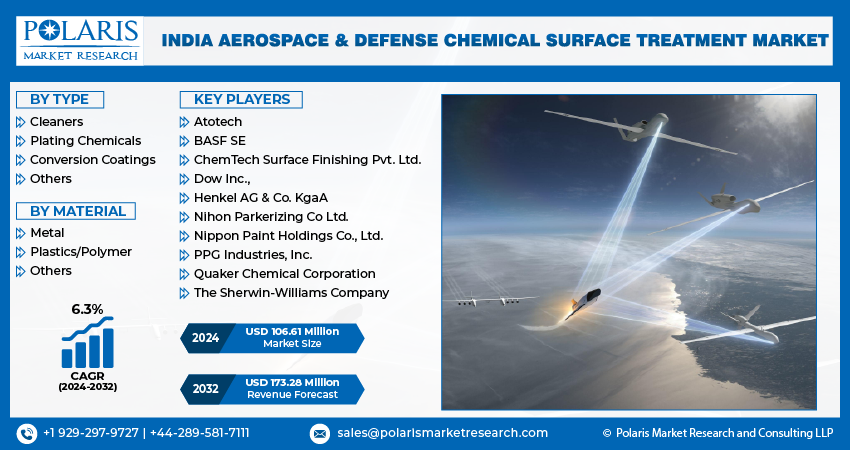

India Aerospace & Defense Chemical Surface Treatment Market size was valued at USD 101.28 million in 2023. The market is anticipated to grow from USD 106.61 million in 2024 to USD 173.28 million by 2032, exhibiting a CAGR of 6.3% during the forecast period.

Industry Trends

The market has witnessed significant growth and evolution in recent years, propelled by a burgeoning defense sector and an expanding aerospace industry. This dynamic landscape is characterized by a growing demand for advanced technologies, modernization initiatives, and the need for superior surface treatment solutions to enhance the durability and performance of aerospace and defense equipment.

The aerospace and defense sector in India has emerged as a key player on the global stage, with increasing investments in research, development, and manufacturing capabilities. As the industry strives for innovation and sophistication, chemical surface treatment has become a critical component in ensuring the longevity and reliability of a wide range of equipment, including aircraft, and other defense systems.

To Understand More About this Research: Request a Free Sample Report

One of the primary drivers of the chemical surface treatment market in the aerospace and defense sector is the need for corrosion resistance. With equipment often exposed to harsh environmental conditions, protecting against corrosion is paramount to ensuring the structural integrity and operational efficiency of aerospace and defense assets. Chemical surface treatments play a pivotal role in safeguarding against corrosion, thereby extending the lifespan of equipment and reducing maintenance costs.

Government initiatives and policies also play a pivotal role in shaping the trajectory of the India aerospace & defense chemical surface treatment market. As the Indian government continues to emphasize indigenization and self-reliance in defense production, there is a growing emphasis on developing domestic capabilities in surface treatment technologies. This not only addresses security concerns but also creates opportunities for local manufacturers to contribute to the supply chain and foster technological innovation.

Key Takeaways

- By type category, the cleaners segment accounted for the largest market share in 2023

- By material category, the metals segment is expected to grow with a significant CAGR over the market forecast period

What are the market drivers driving the demand for India aerospace & defense chemical surface treatment market?

Focus on Aircraft Maintenance, Repair, and Overhaul (MRO)

Aircraft maintenance, repair, and overhaul (MRO) play a pivotal role in ensuring the safety, reliability, and longevity of aircraft, making it a critical aspect of the aerospace and defense industry. The MRO sector is witnessing significant growth and evolving dynamics that drives the market of India aerospace & defense chemical surface treatment. For instance, according to India Brand Equity Foundation, the MRO industry is projected to experience substantial growth, surpassing $2.4 billion by 2028, a significant increase from its 2018 valuation of $800 million.

One of the key driving factors is the rapid modernization of India's defense forces. As the country continues to strengthen its military capabilities, there is an increasing demand for advanced aircraft and aerospace technologies. With a growing fleet of aircraft, both military and civilian, there arises a need for comprehensive maintenance, repair, and overhaul services. This surge in demand for MRO services propels the Aerospace & Defense Chemical Surface Treatment Market forward.

Furthermore, the burgeoning civil aviation sector in India contributes substantially to the growth of the MRO industry. The country's expanding middle class and the government's emphasis on regional connectivity have led to a surge in air travel. This increased air traffic puts additional pressure on airlines to maintain their aircraft to the highest safety standards, thereby driving the demand for MRO services. In this context, chemical surface treatment becomes essential for enhancing the durability and corrosion resistance of aircraft components, ensuring their prolonged service life.

Which factor is restraining the demand for India aerospace & defense chemical surface treatment market?

Growing environmental awareness

In recent years, India has witnessed a significant surge in environmental awareness, with an increasing focus on sustainable practices across various industries, including the aerospace and defense (A&D) sector. The India aerospace & defense chemical surface treatment market, a critical component of the A&D industry, has been subject to this growing environmental consciousness. Companies operating in this market are now analyzing to adopt eco-friendly practices and ensure minimal environmental impact.

The awareness of environmental sustainability in the India aerospace & defense chemical surface treatment market has led to a paradigm shift in industry practices. Companies are increasingly investing in research and development to identify and implement cleaner and greener chemical surface treatment technologies. This shift aligns with global efforts to reduce carbon footprints and mitigate the adverse effects of industrial activities on the environment. The adoption of environmentally friendly surface treatment processes not only meets regulatory requirements but also enhances the corporate image of these companies.

Report Segmentation

The market is primarily segmented based on type and material.

|

By Type |

By Material |

|

|

To Understand the Scope of this Report: Speak to Analyst

Category Wise Insights

By Type Insights

Based on type analysis, the market is segmented on the basis of cleaners, plating chemicals, conversion coatings, and others. In the Indian market, the cleaners segment has emerged as the dominating segment in 2023. Cleaners play a vital role in the surface treatment of aerospace parts to guarantee the quality, reliability, and performance of components. These solutions are highly caustic and serve to prevent corrosion by eliminating salt deposits, corrosive soils, and electrolytes. Cleaners enhance the overall appearance of parts, enabling thorough inspections for corrosion and corrosion-related damage. Additionally, they reduce fire hazards by eliminating accumulations of leaking fluids.

Throughout the manufacturing, handling, or storage of aerospace components, they frequently encounter contaminants such as dirt, grease, oils, rust, and other impurities. These contaminants can have detrimental effects on coating adhesion, compromise material integrity, and contribute to corrosion. Cleaners are employed to effectively eliminate these contaminants, ensuring a pristine and uniform surface. In the aerospace industry, various types of cleaners are utilized for parts' surface treatment. These include alkaline cleaners, aqueous cleaners, solvent emulsion cleaners, turbine engine gas-path cleaners, and more. In summary, cleaners are indispensable in aerospace surface treatment processes, ensuring the cleanliness, adhesion, and longevity of components.

By Material Insights

Based on material analysis, the market is segmented on the basis of metal, plastics/polymer, and others. The metals segment is anticipated to have a significant growth rate over the forecast period in the Indian market. The aerospace industry employs a variety of metals, and chemical surface treatment plays a crucial role in enhancing their longevity. Titanium is extensively utilized in aerospace, necessitating the development of more effective plating processes for this metal. One challenge with titanium is its high reactivity, leading to the rapid formation of an oxide film. Nickel coating finds widespread use in aviation engine components due to its superior durability. The nickel layer is typically chemically stripped, and then oxidized using a reactive oxidizer.

Chemical treatments such as chromate conversion coating are applied to aluminum surfaces after cleaning and pre-treatment to remove contaminants. Anodizing is an essential process in the aerospace industry for enhancing both the durability and aesthetic appeal of aluminum components. This cost-effective and straightforward process involves using chromic acid to form a fine, electrically non-conductive aluminum oxide coating. Phosphate coating is another chemical conversion method where phosphate crystals are formed on material surfaces containing iron phosphates, zinc, manganese. Typically applied to cast iron, low-alloy steel, and carbon steel, phosphate coatings can also be used on cadmium, tin, aluminum, and zinc surfaces. These coatings contribute to the protection and performance of metal components in aerospace applications.

Competitive Landscape

The key players in the India aerospace & defense chemical surface treatment market includes Atotech, BASF SE, ChemTech Surface Finishing Pvt. Ltd., Dow Inc., Henkel AG & Co. KgaA, and Nippon Paint Holdings Co., Ltd. The market is marked by intense competition, with players vying for market share through continual advancements in technology, strategic collaborations, and a commitment to innovation. The industry is witnessing a shift towards environmentally sustainable surface treatment solutions, driven by regulatory pressures and a growing focus on eco-friendly technologies. Companies are actively investing in research and development to stay abreast of evolving industry needs and adhere to stringent quality standards. The competitive landscape is further shaped by a desire for global partnerships within the aerospace and defense sectors, underscoring the dynamic and evolving nature of the market.

Some of the major players operating in the India market include:

- Atotech

- BASF SE

- ChemTech Surface Finishing Pvt. Ltd.

- Dow Inc.,

- Henkel AG & Co. KgaA

- Nihon Parkerizing Co Ltd.

- Nippon Paint Holdings Co., Ltd.

- PPG Industries, Inc.

- Quaker Chemical Corporation

- The Sherwin-Williams Company

Recent Developments

- In May 2023, PPG unveiled a joint venture with Entrotech, named PPG Advanced Surface Technologies, to provide innovative paint and clear film solutions for automotive and industrial applications.

Report Coverage

The India Aerospace & Defense Chemical Surface Treatment market research report provide a better understanding of the product to the users. Also, the report provides market insights into recent developments and trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers an in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides a detailed analysis of the market while focusing on various key aspects such as competitive analysis, type, material, and futuristic growth opportunities.

India Aerospace & Defense Chemical Surface Treatment Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2023 |

USD 106.61 million |

|

Revenue Forecast in 2032 |

USD 173.28 million |

|

CAGR |

6.3% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD million and CAGR from 2024 to 2032 |

|

Segments Covered |

By Type, By Material |

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

India Aerospace & Defense Chemical Surface Treatment market size is expected to reach USD 173.28 Million by 2032

Key players in the market are Atotech, BASF SE, ChemTech Surface Finishing Pvt. Ltd., Dow Inc., Henkel AG & Co. KgaA, Nihon Parkerizing Co Ltd

India Aerospace & Defense Chemical Surface Treatment Market exhibiting a CAGR of 6.3% during the forecast period.

The India Aerospace & Defense Chemical Surface Treatment Market report covering key segments are type and material.