Heat Treated Steel Plates Market Share, Size, Trends, Industry Analysis Report, By Process (Hardening & Tempering, Case Hardening, Annealing), By Application, By Region, And Segment Forecasts, 2024- 2032

- Published Date:Jan-2024

- Pages: 118

- Format: PDF

- Report ID: PM3783

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

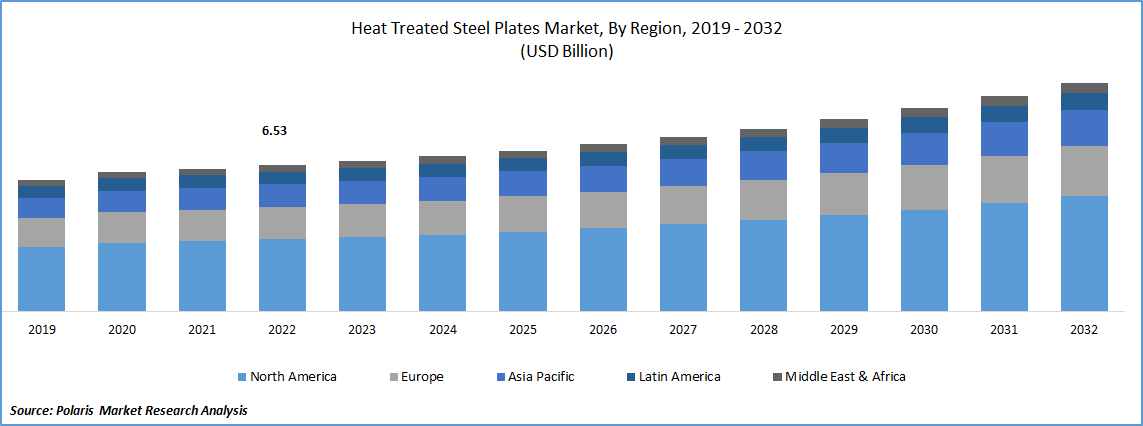

The global heat-treated steel plates market was valued at USD 6.69 billion in 2023 and is expected to grow at a CAGR of 5.00% during the forecast period.

Heat treated steel plates offer a range of desirable properties that make them indispensable for shipbuilding applications. Through carefully controlled heating and cooling processes, these plates attain enhanced strength, durability, and toughness, making them better suited to withstand the harsh marine environment, extreme weather conditions, and the stress of heavy loads. Additionally, heat treated steel plates exhibit improved corrosion resistance, ensuring a longer service life for the vessels.

To Understand More About this Research: Request a Free Sample Report

Structural parts, such as bulkheads, decks, and frames, are the backbone of any vessel's construction. Heat treated steel plates are crucial in reinforcing and strengthening these structural elements, ensuring the vessel's overall integrity and safety. The trend of customization and the focus on specialized vessels in the region require tailor-made structural components, further boosting the demand for heat treated steel plates.

Moreover, the escalating trade activities and increasing globalization have led to a rise in the demand for sea transport, driving the need for larger and more technologically advanced ships. These modern vessels, designed for higher efficiency and larger capacities, often require heat treated steel plates to meet stringent safety and performance standards. As a result, shipbuilders in the South East nations are turning to these specialized steel plates to fulfill the exacting requirements of contemporary marine construction. Furthermore, the proximity of these countries to major shipping routes and international trade hubs adds to their strategic advantage in the shipbuilding industry. By catering to the global demand for new vessels and ship replacements, the region has become a pivotal player in the maritime economy, further propelling the demand for heat treated steel plates.

These nations have become a key player in the global maritime sector, with these countries establishing themselves as major shipbuilders. They are responsible for constructing a substantial portion of the world's commercial vessels, ranging from cargo ships and tankers to passenger vessels and offshore structures. This remarkable growth in shipbuilding capabilities and output necessitates a reliable supply of high-quality materials, particularly heat-treated steel plates, to meet the rigorous demands of maritime construction.

Industry Dynamics

Growth Drivers

Increasing Applications of Heat Treated Steel Plates

Heat treated steel plates are widely preferred in shipbuilding for various critical applications. Offshore equipment used in oil and gas operations, such as platforms, rigs, and subsea structures, must withstand challenging environmental conditions and heavy loads. Heat treated steel plates offer the necessary strength, toughness, and corrosion resistance to endure such demanding offshore environments, making them a preferred choice in this sector. Moreover, ship repair and maintenance are integral aspects of the maritime industry, and heat-treated steel plates find extensive use as repair pieces for damaged or worn-out components. As the shipbuilding sector grows in these Southeast Asian countries, there will be a corresponding increase in the need for ship repair and maintenance services, driving the demand for heat treated steel plates.

Report Segmentation

The market is primarily segmented based on process, application, and region.

|

By Process |

By Application |

By Region |

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Process Analysis

Hardening & Tempering Segment Accounted for the Largest Share in 2022

Hardening & tempering accounted for major global share. This process involves a combination of heating and cooling those results in steel plates with exceptional hardness, strength, and toughness. The advantages of hardening and tempering include reduced material usage, improved machinability, and enhanced formability of the steel plates. Combined effect of hardening and tempering results in steel plates with improved properties. They exhibit exceptional hardness, making them suitable for applications requiring high wear resistance and strength. The process also enhances the toughness of the steel, ensuring it can withstand impact and dynamic loading. This combination of hardness and toughness is crucial for many industrial applications, including manufacturing machinery, construction equipment, and various tools.

Case hardening segment is likely to register highest growth rate. This is primarily due to its numerous advantages, such as cost-effectiveness, high strength, hardness, and the ability to shape complex forms. This process is particularly suitable for low carbon steel products, as they have limited inherent hardenability. The demand for heat treated steel plates in this segment is expected to rise, driven by properties like enhanced wear resistance and the capacity to endure stresses without failure.

Annealing, another essential process, involves heating steel at the very high temperatures & cooling at the room temperature. This treatment aims to improve the ductility and toughness of the steel product. Annealing is typically carried out prior to cold forming to reduce the load & energy to ensure the steel can withstand significant strains without failure.

By Application Analysis

Automotive & Transportation Segment Expected to Hold Substantial Market Share

Automotive & transportation segment is projected to hold significant market share. Steel is highly regarded as a sustainable material due to its recyclability, making it an environmentally friendly choice. As concerns over environmental pollution, product service life, and driving comfort continue to grow. Case hardening is preferred over quench & hardened steel, as the latter may not be sufficient to withstand the bending & rotating stresses experienced by automotive parts. Case hardening offers improved durability and wear resistance, making it an ideal choice for critical components.

Industrial machinery & equipment segment witnessed steady growth. The segment's growth is further bolstered by the increasing demand for various tools used in cutting, drilling, sanding, deformation, & knurling. Among the tools used in this segment, lathe machines are significant consumers of heat-treated steel. These machines rely on heat treated steel plates to achieve the desired hardness, strength, & machinability. As a result, they can effectively perform various manufacturing processes with precision and efficiency.

Regional Insights

APAC Region Dominated the Global Market in 2022

APAC dominated the global market. The region's robust demand for the product can be attributed to the increasing consumption in the several allied industries. Notably, the industrial sector in the region is anticipated to experience significant growth, primarily driven by the key development projects. The region's ambitious infrastructure initiatives encompass a wide range of projects in key sectors such as energy, transportation, information technology, & water transportation. As these projects progress, there will be a substantial need for high-quality steel plates to cater to the construction and manufacturing requirements of critical machinery, equipment, & components.

Middle East is likely to emerge as fastest growing region. This growth can be attributed to the diversification initiatives undertaken by various governments, especially in Gulf Cooperation Council (GCC) countries. These nations are actively working to reduce their reliance on the oil and gas sector and are channeling investments into several areas, including road infrastructure (such as highways and railways), healthcare, water transportation, and other manufacturing sectors.

As part of their economic diversification programs, GCC countries are strategically focusing on developing and improving critical infrastructure and non-oil industries. By investing in projects such as road networks, railways, and water transportation systems, they aim to enhance connectivity and facilitate the movement of goods and people. Additionally, there is a strong emphasis on bolstering healthcare services to cater to the growing population's needs, as well as expanding various manufacturing sectors to promote economic growth and create new employment opportunities.

Key Market Players & Competitive Insights

The heat treated steel plates market is fragmented and is anticipated to witness competition due to several players' presence. Major service providers in the market are constantly upgrading their technologies to stay ahead of the competition and to ensure efficiency, integrity, and safety. These players focus on partnership, product upgrades, and collaboration to gain a competitive edge over their peers and capture a significant market share.

Some of the major players operating in the global market include:

- ArcelorMittal

- Baosteel

- Essar Steel

- JFE Holdings

- Nippon Steel

- Novolipetsk Steel.

- Outokumpu

- POSCO

- Tata Steel

- Thyssenkrupp

Recent Developments

- In June 2023, Outokumpu collaborated with the Thyssenkrupp Materials Processing Europe & Boysen Group to enhance its presence in the automotive industry. The primary goal of this collaboration is to reduce the carbon footprints of steel used in the automotive sector.

- In April 2023, VELUX Group has partnered with the ArcelorMittal. The main objective of this collaboration is to develop methods that will significantly decrease carbon emissions and enhance the energy efficiency of the steel manufacturing process.

Heat Treated Steel Plates Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 6.91 billion |

|

Revenue forecast in 2032 |

USD 10.18 billion |

|

CAGR |

5.00% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Process, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

FAQ's

The heat-treated steel plates market report covering key segments are process, application, and region.

Heat Treated Steel Products Market Size Worth $10.18 Billion By 2032.

The global heat-treated steel plates market is expected to grow at a CAGR of 4.8% during the forecast period.

Asia Pacific is leading the global market.

key driving factors in heat-treated steel plates market are increasing applications of heat-treated steel plates.