HDPE Geogrid Market Size, Share, Trends, Industry Analysis Report: By Type (Biaxial Tension and Uniaxial Tension), By Application, and By Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2024–2032

- Published Date:Aug-2024

- Pages: 115

- Format: PDF

- Report ID: PM5037

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

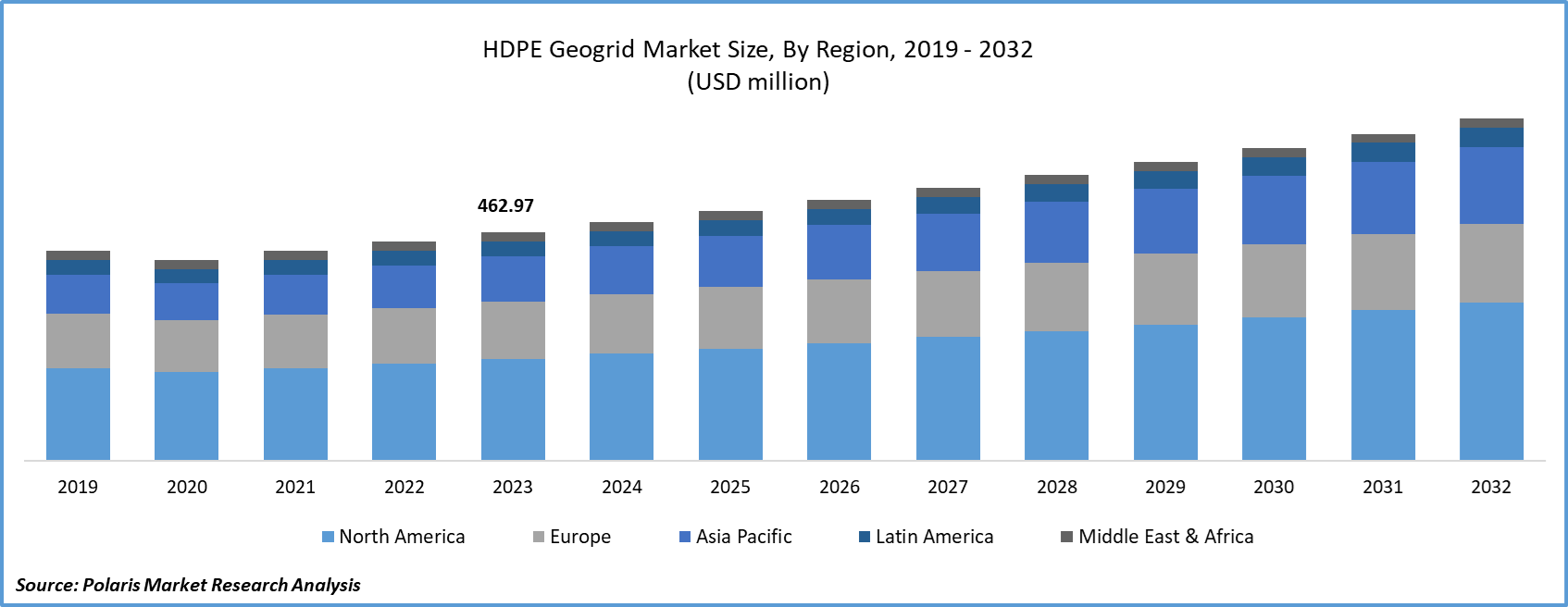

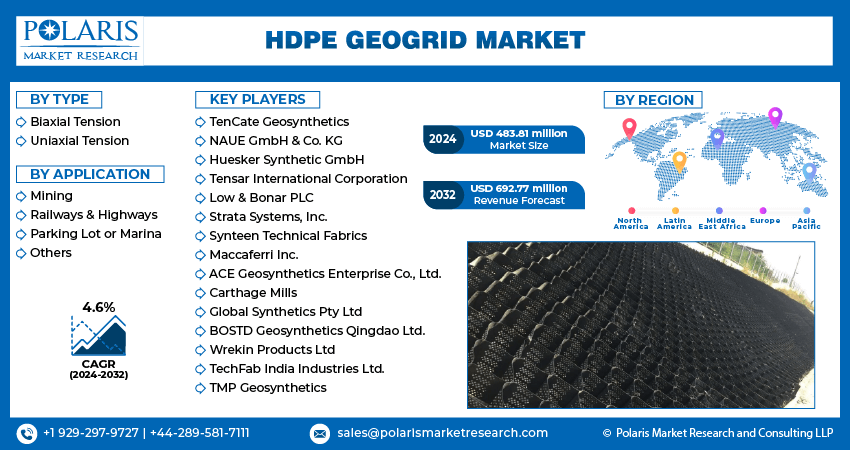

The global HDPE geogrid market size was valued at USD 462.97 million in 2023. The market is projected to grow from USD 483.81 million in 2024 to USD 692.77 million by 2032, exhibiting a CAGR of 4.6% during forecast period.

HDPE geogrid is a type of geosynthetic material made from high-density polyethylene (HDPE) and designed for soil reinforcement and stabilization applications. It consists of a grid-like structure with intersecting ribs that provide strength and support to soil and aggregate layers. The increasing demand for infrastructure development and road construction, rising need for soil stabilization and reinforcement in urban and rural projects, and advancements in HDPE geogrid technology that enhance durability and performance drive the global HDPE geogrid market growth. Trends such as the growing focus on sustainable construction practices and the integration of geosynthetics in various civil engineering applications would contribute to market expansion over the forecast period. Additionally, the adoption of HDPE geogrids in environmental protection and erosion control projects is expected to boost market growth during the forecast period, highlighting the material’s versatility and effectiveness in a range of applications.

To Understand More About this Research:Request a Free Sample Report

HDPE Geogrid Market Outlook

Growing Demand for Sustainable Infrastructure Solutions

The governments and organizations across the globe prioritize eco-friendly construction practices there is a growing demand for HDPE geogrids due to their recyclability, durability, and minimal environmental impact. These geogrids are widely used in green infrastructure projects such as retaining walls, roadways, and embankments, where they help reduce the carbon footprint by minimizing the need for nonrenewable materials. The rising emphasis on sustainability is expected to drive the adoption of HDPE geogrids in construction projects focused on long-term environmental benefits.

Integration of Advanced Manufacturing Technologies

Manufacturers are increasingly adopting new processes such as laser sintering and 3D printing to enhance the precision, strength, and performance of geogrids. These innovations allow for the creation of geogrids with customized properties tailored to specific project requirements, leading to improved load-bearing capacities and resistance to environmental factors. The use of advanced technologies also contributes to cost-efficiency, enabling manufacturers to produce high-quality geogrids at a competitive price, further driving the market growth.

Expansion of Infrastructure Development in Emerging Economies

Countries in Asia Pacific, Africa, and Latin America are investing heavily in road networks, railways, airports, and urban development projects, creating a substantial demand for geosynthetic materials such as HDPE geogrids. These regions are recognizing the benefits of geogrids in enhancing the longevity and stability of infrastructure, particularly in challenging terrains and climates. As these economies continue to grow and urbanize, the demand for HDPE geogrids is expected to rise in the coming years, making it a vital component in the global infrastructure landscape.

HDPE Geogrid Market Segment Insights

HDPE Geogrid Market – Type Insights

The HDPE geogrid market, by type, is segmented into biaxial tension and uniaxial tension. The biaxial tension segment dominates the market, primarily due to their widespread application in road construction, soil reinforcement, and load distribution projects. These geogrids offer high tensile strength in longitudinal and transverse directions, making them ideal for applications requiring enhanced stability and support. Their versatility in a variety of civil engineering projects has solidified their position as the leading segment in the market.

The uniaxial tension segment is expected to witness a higher growth rate in the coming years owing to the increasing demand for geogrids in applications that require reinforcement along a single axis, such as retaining walls, slopes, and embankments. Uniaxial geogrids provide superior performance in situations where stress is applied predominantly in one direction, making them crucial for specific engineering challenges. Rising infrastructure development, particularly in challenging terrains, propels the need for uniaxial tension geogrids.

HDPE Geogrid Market – Application Insights

The HDPE geogrid market, by application, is segmented into mining, railways & highways, parking lot or marina, and others. The railways & highways segment dominates the market, driven by the extensive use of geogrids in road construction, track stabilization, and embankment reinforcement. The demand for HDPE geogrid in the segment is propelled by ongoing infrastructure development projects across the world, particularly in developing regions where there is a strong emphasis on improving transportation networks. The ability of HDPE geogrids to enhance the structural integrity and longevity of railways and highways makes them indispensable in these applications, securing their position as the leading segment.

The parking lot or marina segment is expected to experience the highest growth rate over the forecast period. This growth is fueled by the increasing adoption of geogrids in urban development projects, where there is a growing need for stable and durable surfaces in parking areas and marina constructions. The use of HDPE geogrids in these applications helps prevent surface deformation and enhances load distribution, leading to longer-lasting infrastructure. As urbanization continues to rise and the need for efficient space utilization becomes more critical, the parking lot or marina segment is poised for rapid expansion within the HDPE geogrid market.

HDPE Geogrid Market, Segmental Coverage, 2019 - 2032 (USD million)

Source: Secondary Research, Primary Research, PMR Database and Analyst Review

HDPE Geogrid Market Regional Insights

By region, the study provides the market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific emerges as the dominating region in the global HDPE geogrid market, driven by rapid infrastructure development and urbanization in countries such as China and India. The region's substantial investments in transportation networks, including highways, railways, and urban development projects, have fueled the demand for HDPE geogrids. Additionally, the growing focus on sustainable construction practices and the adoption of geosynthetics in civil engineering boost the Asia Pacific market growth.

North America HDPE geogrid market is expected to witness significant growth over the forecast period due to increasing infrastructure development and construction activities across the region. The rising demand for durable and cost-effective solutions in road construction, railways, and soil reinforcement is driving the adoption of HDPE geogrids, Furthermore, the growing focus on sustainable construction practices and the need for improved ground stabilization in both urban and rural areas are further fueling market growth. Government initiatives and investments in infrastructure projects, coupled with advancements in geosynthetic technologies, are also contributing to the expanding market for HDPE geogrids in North America.

HDPE Geogrid Market Regional Coverage, 2019 - 2032 (USD million)

Source: Secondary Research, Primary Research, PMR Database and Analyst Review

The HDPE geogrid market growth in Europe is driven by the region's focus on modernizing existing infrastructure and enhancing construction quality. Countries such as Germany, the UK, and France are leading the adoption of HDPE geogrids, particularly in road rehabilitation, railway upgrades, and environmental protection projects. The region's stringent regulations on construction standards and environmental impact have driven the demand for high-quality, durable geosynthetics such as HDPE geogrids. Additionally, Europe’s ongoing efforts to incorporate sustainable practices in construction, including the use of recyclable and eco-friendly materials, contribute to the market growth.

HDPE Geogrid Market – Key Players and Competitive Insights

The HDPE geogrid industry is highly competitive, with several key players actively contributing to its growth. Prominent companies in the market are TenCate Geosynthetics; NAUE GmbH & Co. KG; Huesker Synthetic GmbH; Tensar International Corporation; Low & Bonar PLC; Strata Systems, Inc.; Synteen Technical Fabrics; Maccaferri Inc.; ACE Geosynthetics Enterprise Co., Ltd.; Carthage Mills; Global Synthetics Pty Ltd; BOSTD Geosynthetics Qingdao Ltd.; Wrekin Products Ltd; TechFab India Industries Ltd.; and TMP Geosynthetics. These companies play a vital role in advancing the HDPE geogrid market through innovative products, strategic partnerships, and expanding their geographical presence.

Competitive analysis reveals that key market players such as TenCate Geosynthetics and Huesker Synthetic GmbH maintain their dominance by offering a wide range of geosynthetic solutions, including advanced HDPE geogrids, tailored for various civil engineering applications. These companies have a strong global presence, extensive research and development capabilities, and a diverse product portfolio, allowing them to cater to a broad spectrum of customer needs. However, emerging players such as TechFab India and BOSTD Geosynthetics Qingdao Ltd. are focusing on expanding their market share by leveraging cost-effective manufacturing techniques and targeting high-growth regions such as Asia Pacific.

In terms of competitive insights, the HDPE geogrid market is characterized by continuous innovation and a focus on sustainability. Leading companies are increasingly investing in research to develop geogrids with enhanced durability, environmental resistance, and recyclability, aligning with the global trend toward eco-friendly construction practices. Additionally, strategic collaborations and mergers are common as companies aim to expand their product offerings and global reach. This dynamic competitive environment ensures that the market remains vibrant, with significant opportunities for growth and innovation.

TenCate Geosynthetics is a major player in the HDPE geogrid market, known for its extensive range of geosynthetic products that cater to various civil engineering applications, including soil reinforcement, erosion control, and drainage systems. The company has a strong global presence, with manufacturing facilities and distribution networks across multiple continents, allowing it to serve a diverse customer base. TenCate's commitment to innovation is evident in its continuous investments in research and development, which has led to the introduction of advanced geogrid technologies that offer superior performance and sustainability.

Huesker Synthetic GmbH is another major player in the HDPE geogrid market, with a strong reputation for delivering high-quality geosynthetic solutions. The company is particularly noted for its innovative approach to geogrid design, incorporating the latest advancements in material science to improve product performance. Huesker's geogrids are widely used in road construction, embankment stabilization, and environmental protection projects. With a robust presence in Europe and expanding operations in other regions, Huesker plays a crucial role in advancing the geogrid industry.

Key Companies in HDPE Geogrid Market

- TenCate Geosynthetics

- NAUE GmbH & Co. KG

- Huesker Synthetic GmbH

- Tensar International Corporation

- Low & Bonar PLC

- Strata Systems, Inc.

- Synteen Technical Fabrics

- Maccaferri Inc.

- ACE Geosynthetics Enterprise Co., Ltd.

- Carthage Mills

- Global Synthetics Pty Ltd

- BOSTD Geosynthetics Qingdao Ltd.

- Wrekin Products Ltd

- TechFab India Industries Ltd.

- TMP Geosynthetics

HDPE Geogrid Industry Developments

- In March 2024, TenCate Geosynthetics announced the launch of a new line of HDPE geogrids designed specifically for extreme environmental conditions. This new product line focuses on enhancing durability and resistance to UV radiation, making it ideal for use in harsh climates and demanding infrastructure projects.

- In January 2024, Huesker Synthetic GmbH announced a strategic partnership with a construction firm in Europe to develop and implement sustainable geosynthetic solutions for large-scale infrastructure projects. This collaboration aims to leverage Huesker’s expertise in geogrid technology to create durable and environmentally friendly construction methods.

HDPE Geogrid Market Segmentation

HDPE Geogrid – Type Outlook

- Biaxial Tension

- Uniaxial Tension

HDPE Geogrid – Application Outlook

- Mining

- Railways & Highways

- Parking Lot or Marina

- Others

HDPE Geogrid – Regional Outlook

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

HDPE Geogrid Report Scope

|

Report Attributes |

Details |

|

Market size value in 2023 |

USD 462.97 million |

|

Market size value in 2024 |

USD 483.81 million |

|

Revenue forecast in 2032 |

USD 692.77 million |

|

CAGR |

4.6% from 2024 to 2032 |

|

Base year |

2023 |

|

Historical data |

2019–2022 |

|

Forecast period |

2024–2032 |

|

Quantitative units |

Revenue in USD million and CAGR from 2024 to 2032 |

|

Report coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments covered |

|

|

Regional scope |

|

|

Competitive landscape |

|

|

Report format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

How is the report valuable for an organization?

Workflow/Innovation Strategy: The HDPE geogrid market has been broadly segmented on the basis of type and application. Moreover, the study provides the reader with a detailed understanding of the different segments at the global and regional levels.

Growth/Marketing Strategy: The growth and marketing strategy for the HDPE geogrid market centers on expanding product offerings through continuous innovation and strategic partnerships. Companies are focusing on developing advanced geogrids with enhanced durability and environmental sustainability to meet the rising demand for eco-friendly construction materials. Additionally, market leaders are strengthening their global presence by entering high-growth regions such as Asia Pacific and collaborating with local distributors. Aggressive marketing campaigns highlighting the long-term cost benefits and performance advantages of HDPE geogrids are also fueling adoption across various infrastructure projects. This multi-faceted approach is helping companies capture a larger market share while addressing the evolving needs of the construction industry.

FAQ's

The global market size was valued at USD 462.97 million in 2023 and is projected to grow to USD 692.77 million by 2032.

The global market is projected to register a CAGR of 4.6% during 2023–2032.

Asia Pacific accounted for the largest global market share.

TenCate Geosynthetics; NAUE GmbH & Co. KG; Huesker Synthetic GmbH; Tensar International Corporation; Low & Bonar PLC; Strata Systems, Inc.; Synteen Technical Fabrics; Maccaferri Inc.; ACE Geosynthetics Enterprise Co., Ltd.; Carthage Mills; Global Synthetics Pty Ltd; BOSTD Geosynthetics Qingdao Ltd.; Wrekin Products Ltd; TechFab India Industries Ltd.; and TMP Geosynthetics are among the prominent companies operating in the market.

The biaxial tension segment dominated the market in 2023.

The railways and highways segment held the largest market share.

HDPE geogrid is a type of geosynthetic material made from high-density polyethylene (HDPE) and designed for soil reinforcement and stabilization applications. It consists of a grid-like structure with intersecting ribs that provide strength and support to soil and aggregate layers. HDPE geogrids are used to enhance the stability and load-bearing capacity of structures such as roadways, embankments, and retaining walls by distributing loads more evenly and reducing soil deformation.

A few of the key trends observed in this market are described below: Sustainability Focus: Increased emphasis on eco-friendly construction practices and the use of recyclable materials drives the adoption of HDPE geogrids, which are valued for their durability and minimal environmental impact. Technological Advancements: Integration of advanced manufacturing technologies such as 3D printing and laser sintering enhances the performance and customization of HDPE geogrids, leading to improved load-bearing capacities and resistance. Infrastructure Development: Growing investments in infrastructure projects, particularly in emerging economies, boost the demand for HDPE geogrids for applications in roads, railways, and urban development. Enhanced Durability: Development of HDPE geogrids with improved resistance to UV radiation, chemicals, and extreme weather conditions caters to the need for longer-lasting and robust construction materials.

For a new company entering the HDPE geogrid market, focusing on innovation and sustainability can provide a competitive edge. Emphasizing the development of advanced geogrid technologies with enhanced durability, resistance to environmental factors, and eco-friendly features will attract clients seeking high-performance and sustainable solutions. Additionally, establishing strategic partnerships with local distributors in high-growth regions such as Asia Pacific can help gain market presence and access to emerging infrastructure projects. Leveraging data-driven insights to tailor products to specific regional needs and maintaining a strong focus on customer support and education can differentiate the company from established competitors.

Companies offering HDPE geogrids and related products and other consulting firms must buy the report.