Powder Coating Equipment Market Share, Size, Trends, Industry Analysis Report, Application (Automotive, Industrial, Consumer goods, Furniture, Building & Construction, and Others); By Type; By Region; Segment Forecast, 2022 – 2030

- Published Date:Oct-2022

- Pages: 124

- Format: PDF

- Report ID: PM1285

- Base Year: 2021

- Historical Data: 2018 - 2020

Report Outlook

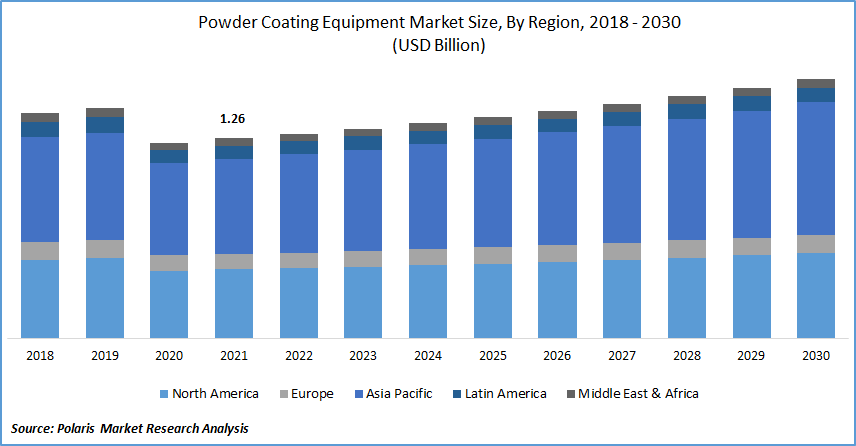

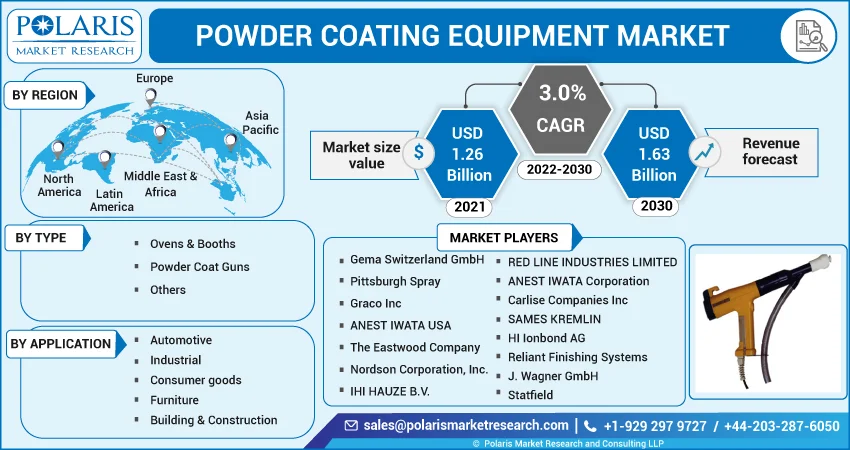

The global powder coating equipment market is valued at USD 1.26 billion in 2021 and is projected to grow at a CAGR of 3.0% during the forecast period. Diversifying the array of equipment and complex systems that needs ultra-quality coating to enhance their lifeline has amplified the demand for coatings, which sequentially raises the market necessity. The acquisition and implementation of significant technologies in the coating industry, such as Artificial Intelligence, IoT, and nanotechnology.

Know more about this report: Request for sample pages

Moreover, the soaring application of massive machinery in the manufacturing industry also, trends in vehicle sales in all sectors, general lifestyle activities, and healthy economic ambiances give a positive boost to the global coating equipment market. The spreading acceptance of coatings to safeguard surfactant/monolayers from changing environmental effects will boost the growth of the coating equipment sector.

Scientific reforms for creating advanced coating equipment unanimous with the variety of coating stuff has occupied a new entrechat of growth on account of the manufacturers and market subsequent requirements; this actuation is serving the coating equipment market to become a flavorsome sector in terms of volume, profit, and sales.

Stupefy repositioning in the progressive countries of the Asia Pacific and, Middle East & Africa from an oil-based economy to a tourism/hospitality industry has brought numerous opportunities for segment growth. All these prominent factors are boosting the market growth of global coating equipment during the forecast period 2020-2030.

The universal acceptance of electric vehicles will foster the development of the coating equipment market. Coatings are necessary for protecting the body/spare parts of EVs and keeping their components rust and environmental damage free. The tactical collaborations between coating equipment end users and manufacturers sector major players have evolved as a considerable trend influencing the market.

For example, Nordson Industrial Coating Systems (ICS) a US-situated supplier of equipment for the explicit application of commercial coating solutions, publicize a prudent union with Zoomlion Group, a China-located construction equipment firm to deliver robotic powder coating technology in November 2019.

Due to the COVID-19 pandemic, the shutdown of manufacturing functions, deadlock in supply chain modules, and reduction in demand for commercial goods had drastically impacted the market. Although, during the COVID-19 pandemic, the great level of requirement for medicine sector-related commodities has taken a jump, which, in response, helps for the growth of the coating equipment market. Concurrently, due to the hysteria situation, individuals stock pharmaceutical and hygiene products across the world which drives the market growth.

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

Expeditious economic growth and expanding urbanization are the prominent growth factors. In addition, with, the acceptance of huge manufacturing plants and the automobile segment are playing a significant role in the development of the coating equipment market globally. The promising requirement for coating on subservient sectors like Furniture, medicine category, construction industry, etc. is creating market development across the globe.

The implementation of modern technology in the coating fragment is projected to thrust market growth. The maneuver of AI and IoT in the coating equipment sector is transforming the face of the coating section. Efficient technologies and data analytics software assure genuine utilization, decrease financial loss, and are trustworthy.

Report Segmentation

The market is primarily segmented based on type, application, and region.

|

By Type |

By Application |

By Region |

|

|

|

Know more about this report: Request for sample pages

Powder Coating Equipment Market, By Product

By Guns, the segment powder coating equipment by gun applies the powdered coat to an exterior using electric spray system. The electronic charge (negative & positive) attracts the paint molecules on the object surface, strongly grasp them stick and produce a polished and equally finished shell. Compared to other kind of paint which consists of solvents for function, the powder-based coating utilizes only dry constituents that are placed electro statically and then put under warm environment. This procedure provides an appealing, steady finish with zero false.

Powder coatings fabricators like Jotun, PPG, and Akzo Nobel, are specifically pointing to their powder coatings framework in fast moving consumer goods section, particularly to provide high-quality finishing and long-lasting shining leading to a growing demand for powder coating equipment.

The growth for powder coating equipment in automotive applications is anticipated to witness high growth based on the expanding EV sector combined with the developing acceptance of powder coatings in automobile fabrication of spare parts as well. The batteries need heat control with respect to fire resistance and reverse bipolar currents that powder coating equipment can offer to lead to the demand of the market.

Building & Construction Sector Occupied the Prominent Market Share in 2021

The growth of the residential/commercial construction segment is anticipated to boost the development for powder coatings in designer/architectural design supplications. Powder coating on AL exterior is projected to be the key driver as it offers low VOC and sustainability.

The Furniture sector is anticipated to manifest paramount growth figure. The reasoning behind this is the expansion in government funding covering countries to reinforce their aviation customers, also the development in the number of air traveler the due to the economical of air fares, has risen the operation hours of airlines as well as the number of flights are factors responsible for the Aviation industry growing at the rapid rate proportionally developing the powder coating equipment market.

Powder coatings are also applied rapidly in the furniture sector for both indoor and outdoor prosecutions. The major advantages of applying powder coatings in this industry including higher-level rust resistance, luxury touch & feel attributes, elevated durability, and rich looks. Plus, powder coatings equipment available in a big variety of colors and finishes options which grant furniture producers to pick the suitable coating choice to figure out perfect product’s design requirements.

APAC Region Held the Prominent Share of the Global Market in 2021

APAC region leads the global market for powder coating equipment in 2021. Fast pace urbanization and expanding industrialization in the region, associated with growing public framework, increasing FMCG demand, such as China, South Korea, and India, are the prime factors superintend to showcase a positive impression on the market growth over the projection phase.

Growing local manufacturing and near-shoring sector in the U.S. is anticipated to boost the development for powder coating equipment in the country. The firm attention of the U.S. government on coatings that are VOC free is projected to showcase the huge demand for powder coating equipment in the country over the projection frame.

The booming production of EVs in Europe region associated with the existence of prominent automobile manufacturers such as BMW AG, Stellantis NV, Volkswagen, and others is anticipated to enhance the demand for powder coatings and evetually the powder coating equipment over the study frame. Additionally, technological improvements in product quality development to standard productivity and energy savings aspects are anticipated to boost the powder coating equipment market.

Competitive Insight

Some of the key players operating in the global powder coating equipment include Gema Switzerland GmbH, Pittsburgh Spray, Graco Inc, ANEST IWATA USA, The Eastwood Company, Nordson Corporation, Inc., IHI HAUZE B.V., RED LINE INDUSTRIES LIMITED, ANEST IWATA Corporation, Carlise Companies Inc, SAMES KREMLIN, HI Ionbond AG, Reliant Finishing Systems, J. Wagner GmbH, Statfield, and Others.

Recent Developments

- In April 2022, Biocoat, Inc, a major manufacturer of medical equipment coating equipment and hydrophilic biomaterial coatings, globally notified the release of EMERGE, hydrophilic coating equipment as offers a domestic dip coating process for pharmaceutical equipment.

- In 2020, Tosoh Corporation organization inaugurated the full-sized function of its modern R&D station situated in Shuan city, China.

- In February 2019, Graco launched modern cordless Spraying Technology. This Sprayer governance System is involved with a multitude of electric-powered airless sprayers that offer real-time location and spray quality & quantity statics. It can be accessed with Wi-Fi to encounter the requirement of the business-class person, executives, and paint job workers.

Powder Coating Equipment Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 1.26 billion |

|

Revenue forecast in 2030 |

USD 1.63 billion |

|

CAGR |

3.0% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

Product, Application, and Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Key companies |

Gema Switzerland GmbH, Pittsburgh Spray, Graco Inc, ANEST IWATA USA, The Eastwood Company, Nordson Corporation, Inc., IHI HAUZE B.V., RED LINE INDUSTRIES LIMITED, ANEST IWATA Corporation, Carlise Companies Inc, SAMES KREMLIN, HI Ionbond AG, Reliant Finishing Systems, J. Wagner GmbH, Statfield, and Others. |