Fill Finish Manufacturing Market Share, Size, Trends, Industry Analysis Report

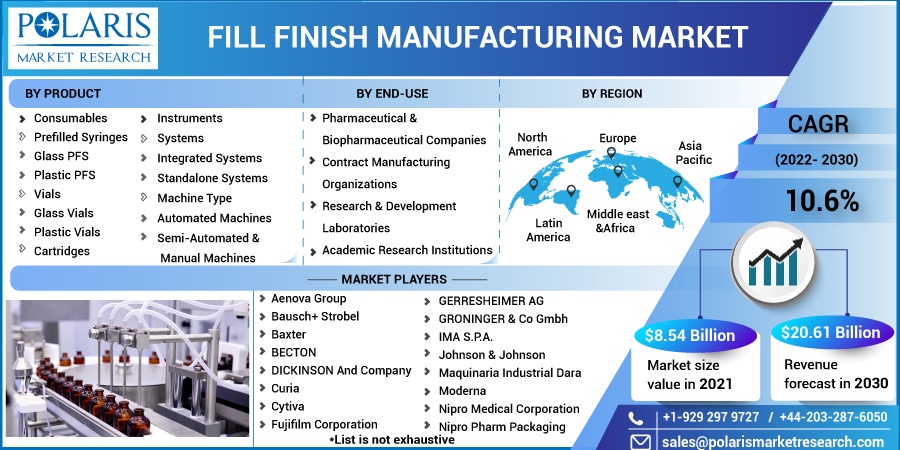

By Product; By End-Use; By Region (North America, Europe, Asia Pacific, Latin America, Middle East &Africa); Segment Forecast, 2022 - 2030

- Published Date:Nov-2022

- Pages: 114

- Format: PDF

- Report ID: PM2723

- Base Year: 2021

- Historical Data: 2018-2020

Report Outlook

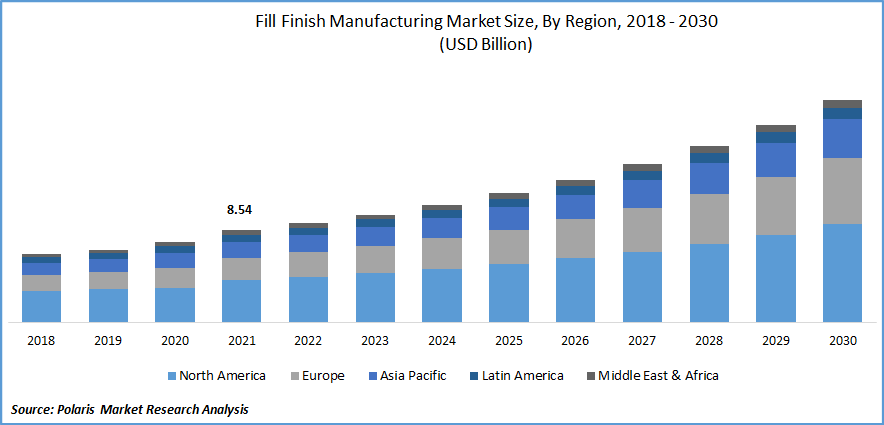

The global fill finish manufacturing market was valued at USD 8.54 billion in 2021 and is expected to grow at a CAGR of 10.6% during the forecast period. The growing demand for fill-finish manufacturing is expected to be driven by rising demand for affordable drugs and increasing adoption of prefilled syringes.

Know more about this report: Request for sample pages

Fill-finish processes are replacing conventional manufacturing processes owing to their self-sterilization and reduced human intervention. In addition, technological advancements in fill finish manufacturing, such as robotic machines used to handle vials and syringes, are expected to accelerate the market over the forecast period.

Furthermore, robotic production requires less maintenance and makes end products reliable and clean in an aseptic fill finish, ultimately reducing operating costs and propelling market growth.

The COVID-19 pandemic has positively influenced the growth of the fill finish manufacturing market. The demand for antiviral drugs and vaccines peaked during the pandemic. In addition, product quality and safety were the primary concern during the pandemic period. Fill finish produced end pharmaceutical products with sterilization and less human contact, ultimately boosting the market growth.

Fill finish processes are mainly operated on isolators and restricted-access barrier systems (RABS), which prevent the risk of contamination in the environment. These systems provide a better environment for manufacturing various biopharmaceutical products but are at a higher price.

Most small-scale companies find it challenging to adopt these technologies due to their expense and look for alternatives restraining market growth.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The global fill finish manufacturing market is likely driven by an increasing number of biopharmaceutical companies and growing demand for biologics in developed and developing nations. In addition, while manufacturing various biopharmaceutical products, novel procedures and equipment play an important role in maintaining product integrity, which is preserved during the fill-finish procedure, thus boosting the market growth.

The rising penetration of contract manufacturing organizations (CMO) in various biotech companies is also considered a significant factor in driving market growth. Many small-scale biotechnological and biopharmaceutical companies are inclined to outsource their fill finish operation to CMO, as the overall development cost are incurred by both the CMO and the company, and chances of risk are lowered, which ultimately bolster the market growth.

Moreover, the CMO has great technical skills, which help in the innovation of various drug discoveries and maintain financial stability. For instance, Berkshire's sterile manufacturing CMO developed a new sterile fill finish procedure for clients having limited drug products. It was observed that 1.1 L of drug product could be produced in a single run, which ultimately reduced product loss.

Report Segmentation

The market is primarily segmented based on product, end-use, and region.

|

By Product |

By End-Use |

By Region |

|

|

|

Know more about this report: Request for sample pages

Consumable segment accounted for the largest share in 2021

The consumable segment accounted for the highest revenue share in 2021, owing to longer shelf life and rising use of disposable packaging for biologics. In addition, the prefilled syringes (PFS) are expected to support the market revenue due to the growing adoption of PFS in various applications such as lyophilization and increasing fill finish outsourcing.

Furthermore, PFS delivers both conventional and novel medications with complex drug molecules with less error and prevents overfilling, which is an essential factor in driving market growth over the forecast period.

Contract manufacturing organization is expected to account for the largest share in 2030

The contract manufacturing organization (CMO) segment is expected to dominate the market over the forecast period owing to the increasing new medications and outsourcing manufacturing of drug substances. In addition, CMO offers drug development services and handles drug innovation during the pharmaceutical industry's manufacturing process, which is an essential factor in propelling the market.

Moreover, CMO is an expertise that not only reduces the financial risk but also outsources the production process of pharmaceutical and biologics companies to improve their process effectiveness, accelerating market growth.

Europe is expected to dominate and witness fastest growth over the forecast period

Europe accounted for the highest share and is expected to witness faster growth over the forecast period owing to the rising concerns of chronic disorders in the geriatric population and innovation in various drug developments. In addition, growing R&D investments in developing affordable biologics in regions such as France, Italy and Germany are expected to drive market growth over the forecast period.

Asia Pacific is expected to be the second largest region for fill finish manufacturing market on account of the growing government investment to improve healthcare infrastructure and clinical research Centers. In addition, the growing penetration of contract manufacturing organizations with many leading pharmaceutical companies and increasing construction of fill-finish plants in regions such as China, Japan, and India is expected to drive market growth.

Competitive Insight

Some of the major players operating in the global market include Aenova Group, Bausch+ Strobel, Baxter, BECTON, DICKINSON And Company, Curia, Cytiva, Fujifilm Corporation, GERRESHEIMER AG, GRONINGER & Co Gmbh, IMA S.P.A., Johnson & Johnson, Maquinaria Industrial Dara, Moderna, Nipro Medical Corporation, Nipro Pharm Packaging, Optima Packaging Group GmbH, Piramal Pharma Solutions, Robert Bosch, Schott AG, SGD Pharma, Stevanato Group, Thermo Fisher Scientific, and West Pharmaceutical Services.

Recent Developments

In March 2022, SGD pharma launched its ready-to-use sterile 100 ml molded glass vials which protect drug stability and eliminates scratches on vials to enhance visual inspection. This type I molded glass vials are used for fill finish parental drug products.

In February 2022, Moderna and Thermo Fisher scientific underwent long-term strategic collaboration to scale up the range of aseptic fill-finish manufacturing of Spikevax, Covid-19 vaccines, and different mRNA medicines in the U.S.

Fill Finish Manufacturing Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2022 |

USD 9.21 billion |

|

Revenue forecast in 2030 |

USD 20.61 billion |

|

CAGR |

10.6% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Product, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key companies |

Aenova Group, Bausch+ Strobel, Baxter, BECTON, DICKINSON And Company, Curia, Cytiva, Fujifilm Corporation, GERRESHEIMER AG, GRONINGER & Co Gmbh, IMA S.P.A., Johnson & Johnson, Maquinaria Industrial Dara, Moderna, Nipro Medical Corporation, Nipro Pharm Packaging, Optima Packaging Group GmbH, Piramal Pharma Solutions, Robert Bosch, Schott AG, SGD Pharma, Stevanato Group, Thermo Fisher Scientific, and West Pharmaceutical Services. |