Fast Curing Nitrile Butadiene Rubber Market Size, Share, Trends, Industry Analysis Report: By Product, Application (Medical, Construction, Metallurgy & Mining, Oil & Gas, Mechanical Engineering, and Automotive), and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Mar-2025

- Pages: 117

- Format: PDF

- Report ID: PM1481

- Base Year: 2024

- Historical Data: 2020-2023

Fast Curing Nitrile Butadiene Rubber Market Overview

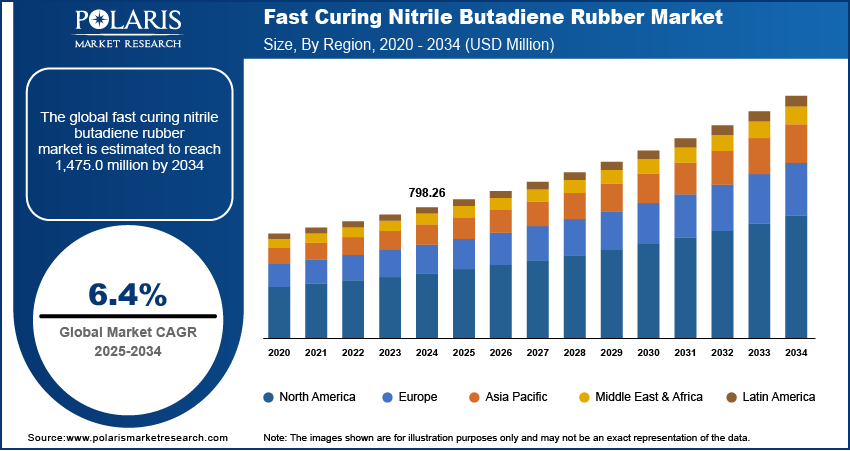

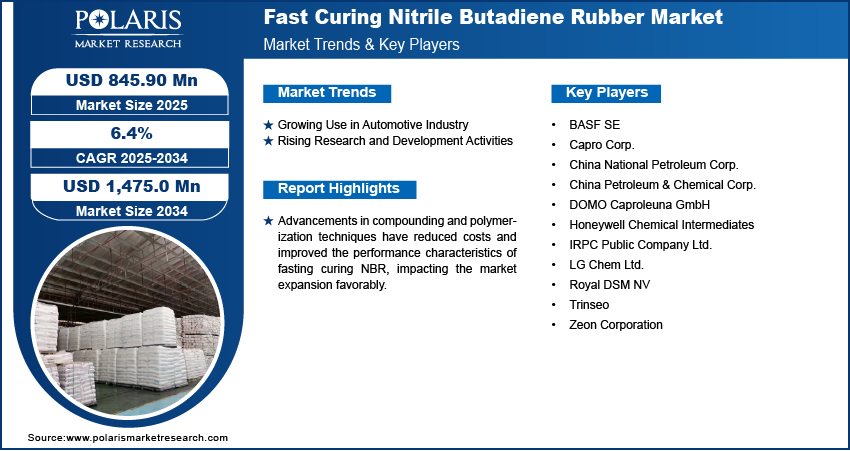

The global fast curing nitrile butadiene rubber market size was valued at USD 798.26 million in 2024. The market is projected to grow from USD 845.90 million in 2025 to USD 1,475.0 million by 2034, at a CAGR of 6.4% from 2025 to 2034.

Fast curing nitrile butadiene rubber (NBR) is a synthetic rubber compound made from acrylonitrile and butadiene. The rubber is known for its resistance to chemicals, oil, and heat. It finds applications in various industries, including automotive, construction, consumer items, and industrial machinery, to create hoses, and gaskets and seals.

The growing construction activities globally are driving the fast curing nitrile butadiene rubber market growth. Infrastructure projects such as buildings, bridges, and roads necessitate strong materials like fast curing NBR to endure challenging environmental conditions. Fast curing NBR is used in various construction applications, including flooring, roofing membranes, and adhesives & sealants, due to their high elasticity and excellent weather resistance. Additionally, advancements in compounding and polymerization techniques have reduced costs and improved the performance characteristics of fasting curing NBR, impacting the market expansion favorably.

The development of fuel efficient engines and the incorporation of advanced technologies in vehicles is driving the need for robust and reliable components made from high-quality materials like fast curing nitrile butadiene rubber. The rising usage of fast curing NBR in machinery, manufacturing equipment, and other vital industrial components is expected to support market development in the coming years.

To Understand More About this Research: Request a Free Sample Report

Fast Curing Nitrile Butadiene Rubber Market Dynamics

Growing Use in Automotive Industry

The rising demand for vehicles worldwide has led to automakers seeking durable and long-lasting materials to produce various automotive components. The desirable properties of fasting curing NBR, including chemical resistance, abrasion resistance, and water resistance, make it a great choice for automotive applications. Automotive seals, gaskets, and hoses made from fasting curing NBR can withstand harsh operating conditions due to their exceptional oil, fuel, and abarasion resistance. The use of fast-curing NBA also reduces the possibility of leaks and improves the longevity and performance of automobiles. Thus, the growing use of fast curing NBR in automotive applications is propelling the fast curing nitrile butadiene rubber market revenue.

Rising Research and Development Activities

Growing research and development (R&D) activities by major market participants have resulted in the development of advanced NBR grades with improved performance and characteristics. In addition, manufacturers are continually seeking ways to improve the mechanical qualities, thermal stability, and chemical resistance of fast-curing NBR. This has led to the introduction of specialist NBR formulations that are tailored for diverse applications across various industries, including oil & gas, aerospace, and automotive. As a result, the increased focus on research and innovation is fueling the fast curing nitrile butadiene rubber market expansion.

Fast Curing Nitrile Butadiene Rubber Market Segment Insights

Fast Curing Nitrile Butadiene Rubber Market Evaluation by Product Insights

The fast curing nitrile butadiene rubber market segmentation, based on product, includes foamed products, gloves, cables, hoses, molded & extruded products, belts, rubber compounds, seals & O-rings, adhesives & sealants, and others. The hoses segment accounted for the largest market share in 2024. Hoses made from fast curing NBR have excellent abrasion, weather, and chemical resistance, enabling them to withstand the harsh climatic conditions of building and infrastructure projects. In addition, the high demand for durable and reliable hoses in automotive applications contributes to the segment’s leading market position.

The belts segment is projected to register the fastest growth from 2025 to 2034. Fast curing NBR belts have high durability and excellent mechanical properties, making them ideal for automated systems where dependability is crucial. The development of fast and effective curing procedures has led to the development of high-quality NBR belts at reduced costs. This has improved the application areas of fast curing NBR belts, thereby contributing to the segment’s robust growth.

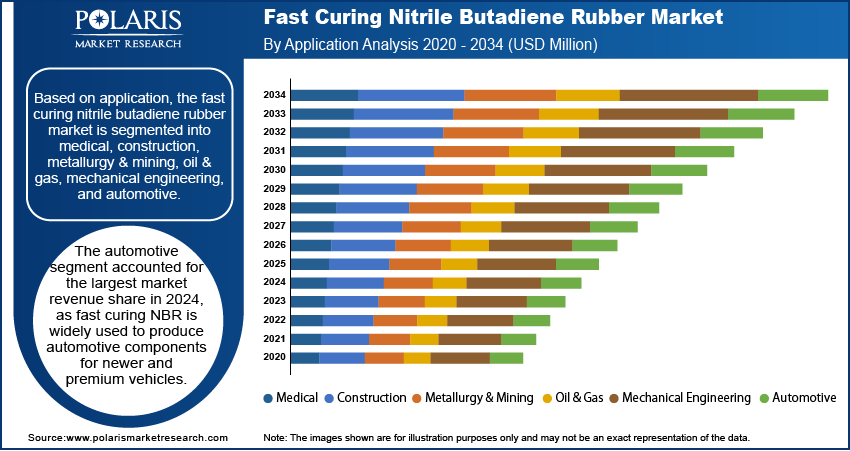

Fast Curing Nitrile Butadiene Rubber Market Assessment by Application Insights

Based on application, the fast curing nitrile butadiene rubber market is segmented into medical, construction, metallurgy & mining, oil & gas, mechanical engineering, and automotive. The automotive segment accounted for the largest market revenue share in 2024, as fast curing NBR is widely used to produce premium seals, gaskets, and hoses for newer and premium vehicles. The development of advanced engine technologies and the growing adoption of electric vehicles (EVs) have led to increased demand for specialized rubber parts that can withstand harsh operating conditions. Manufacturers are increasingly using fast curing NBR to produce automotive rubber components as they help reduce expenses and meet the rising demand for quick vehicle delivery. This, in turn, contributes to the segment’s dominance in the market.

Fast Curing Nitrile Butadiene Rubber Market Regional Analysis

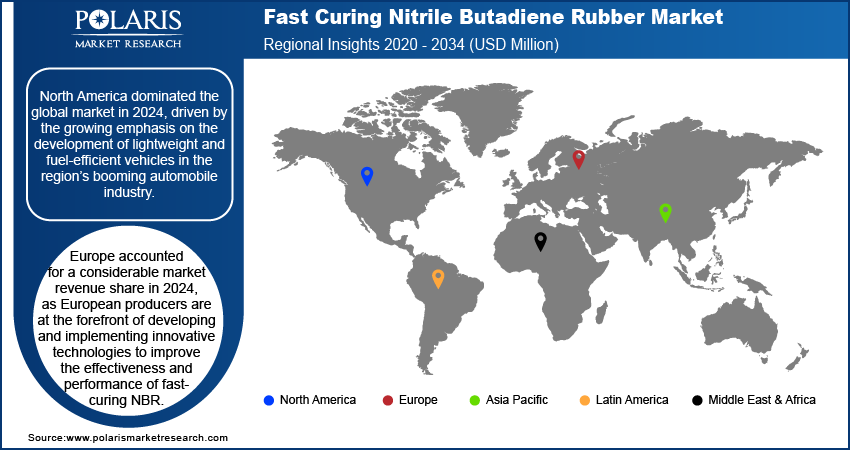

By region, the report provides the fast curing nitrile butadiene rubber market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America dominated the global market in 2024. This is attributed to the growing emphasis on the development of lightweight and fuel-efficient vehicles in the region’s booming automobile industry. In addition, rising consumer preference for advanced features and stricter emissions regulations have led to increased demand for robust and high-performing rubber components in vehicles. The increased need for rubber-based products in infrastructure and construction projects further contributes to the regional market dominance.

The Europe fast curing nitrile butadiene rubber market held a significant market share in 2024. European producers lead the development and adoption of advanced technologies that improve the efficiency and performance of fast curing NBR. Advances in polymer formulations and curing techniques have enhanced the material's overall quality, strength, and flexibility. These developments enable the production of high-performance fast curing NBR products that meet the stringent demands of various industries, thereby contributing to the segment’s substantial market share.

Fast Curing Nitrile Butadiene Rubber Market – Key Players and Competitive Insights

The market is characterized by intense competition, driven by factors such as innovative product offerings, technological advancements, mergers and acquisitions, and other strategic partnerships. The key players in the market strive to differentiate themselves in terms of pricing, quality, offering, and customer service. Also, they are making significant investments in R&D initiatives and focusing on strategic developments such as partnerships and collaborations to introduce advanced fast curing NBR that caters to diverse consumer needs.

Several market participants are prioritizing the development of sustainable and eco-friendly fast curing NBR that complies with stringent government regulations. The fast curing nitrile butadiene rubber market research report offers a market assessment of all the leading players, including BASF SE, China National Petroleum Corp., Capro Corp., DOMO Caproleuna GmbH, Honeywell Chemical Intermediates, China Petroleum & Chemical Corp., Royal DSM NV, LG Chem Ltd., Trinseo, Zeon Corporation, and IRPC Public Company Ltd.

List of Fast Curing Nitrile Butadiene Rubber Market Key Players

- BASF SE

- Capro Corp.

- China National Petroleum Corp.

- China Petroleum & Chemical Corp.

- DOMO Caproleuna GmbH

- Honeywell Chemical Intermediates

- IRPC Public Company Ltd.

- LG Chem Ltd.

- Royal DSM NV

- Trinseo

- Zeon Corporation

Fast Curing Nitrile Butadiene Rubber Industry Developments

In February 2024, LANXESS AG announced the completion of the expansion of its Rhenodiv production unit at the Jhagadia site. According to LANXESS AG, the strategic move will help it improve its fast curing nitrile butadiene rubber production capacity to meet the growing demand of the Indian Sub-continent and the Asian tire and rubber goods markets.

In December 2023, Synthos S.A. and OMV announced the signing of a memorandum of understanding (MoU) to cooperate on sustainability. According to OMV, the partnership will focus on the development of synthetic rubber for high-performance tires.

Fast Curing Nitrile Butadiene Rubber Market Segmentation

By Product Outlook

- Foamed Products

- Gloves

- Cables

- Hoses

- Molded & Extruded Products

- Belts

- Rubber Compounds

- Seals & O-rings

- Adhesives & Sealants

- Others

By Application Outlook

- Medical

- Construction

- Metallurgy & Mining

- Oil & Gas

- Mechanical Engineering

- Automotive

By Regional Outlook

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Fast Curing Nitrile Butadiene Rubber Market Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 798.26 million |

|

Market Size Value in 2025 |

USD 845.90 million |

|

Revenue Forecast by 2034 |

USD 1,475.0 million |

|

CAGR |

6.4% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD million and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The fast curing nitrile butadiene rubber market was valued at USD 798.26 million in 2024 and is projected to grow to USD 1,475.0 million by 2034.

The market is projected to register a CAGR of 6.4% from 2025 to 2034.

North America dominated the global market in 2024.

BASF SE, China National Petroleum Corp., Capro Corp., DOMO Caproleuna GmbH, Honeywell Chemical Intermediates, China Petroleum & Chemical Corp., Royal DSM NV, LG Chem Ltd., Trinseo, Zeon Corporation, and IRPC Public Company Ltd are a few of the key market players.

The hoses segment held the largest market share in 2024.

The automotive segment held the largest market revenue share in 2024.