Extruded Polystyrene Market Share, Size, Trends, Industry Analysis Report, By Application (Basement, Foundation, Wall, Roof, Floor & Ceiling, Below Ground, Others); By End-Use; By Region; Segment Forecast, 2024 - 2032

- Published Date:Feb-2024

- Pages: 118

- Format: PDF

- Report ID: PM4499

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

Market Outlook

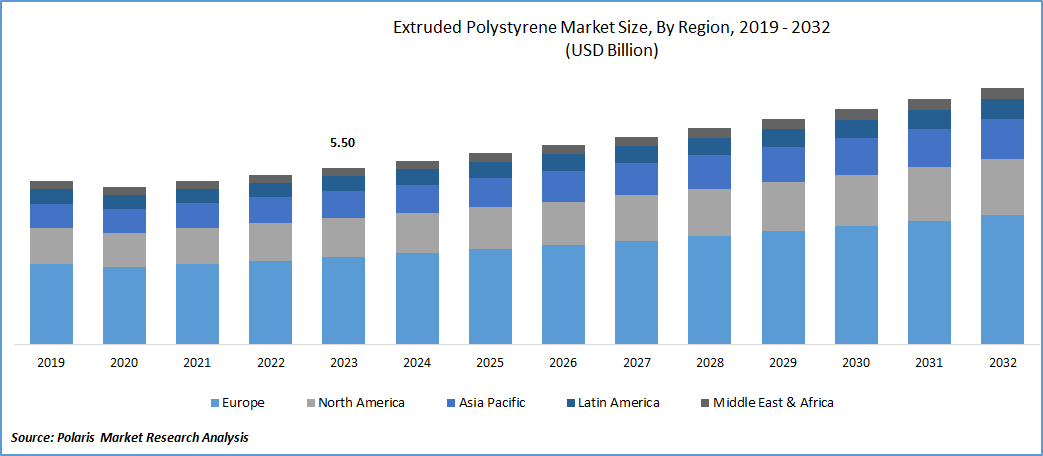

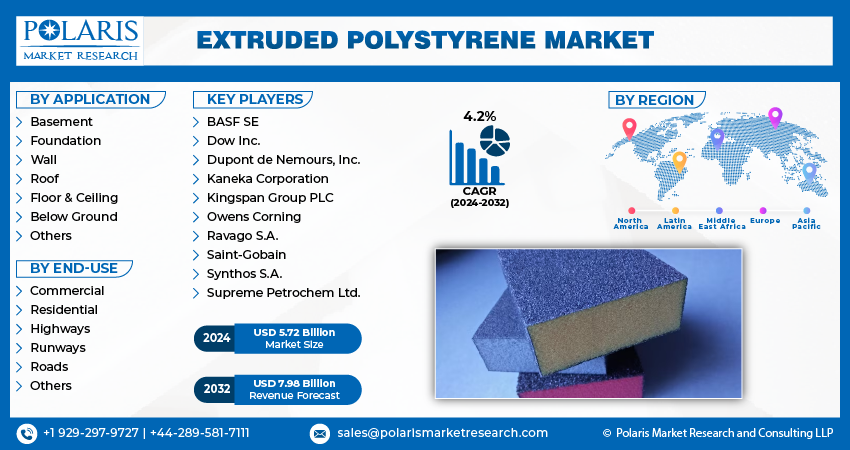

Extruded polystyrene market size was valued at USD 5.50 billion in 2023. The market is anticipated to grow from USD 5.72 billion in 2024 to USD 7.98 billion by 2032, exhibiting the CAGR of 4.2% during the forecast period

Extruded Polystyrene Market Overview

Extruded polystyrene is extensively used in the construction industry owing to its resistance to moisture, high compressive strength, and potential to maintain insulating properties over time, contributing to sustainability and energy efficiency in numerous projects in several industries such as commercial, residential, and others.

To Understand More About this Research: Request a Free Sample Report

Extruded polystyrene provides excellent thermal insulation, making it ideal for use in construction projects such as floors, foundations, walls, and roofs. Its closed-cell structure effectively resists moisture absorption, ensuring long-lasting performance and structural integrity. Extruded polystyrene is a type of polystyrene foam distinguished by its closed-cell structure produced by the extrusion process. Extruded polystyrene, which is widely used in construction applications such as basements, pipelines, and floors, is the best thermal insulation material available. These systems use air as an insulator, resulting in a densely packed structure with excellent moisture resistance.

Extruded polystyrene insulation boards efficiently reduce heat loss in cold environments while effectively preventing heat gain in warm conditions. The use of extruded polystyrene improves building energy efficiency, lowering heating and cooling costs and creating more comfortable indoor environments. Using extruded polystyrene insulation provides numerous benefits. To begin with, its high compressive strength enables it to withstand significant loads without significant deformation.

Further, owing to its characteristics, it is used in situations where the situation is under mechanical stress, such as covered concrete slabs or roads. In addition, extruded polystyrene has a low water absorption rate, increasing its resistance to moisture and preserving its insulating properties over time. Even in humid environments, it maintains thermal efficiency and resists the growth of mold and mildew. Furthermore, extruded polystyrene has exceptional dimensional stability, is lightweight, and is easy to manage, ensuring long-term effectiveness.

The increasing focus on energy efficiency and sustainable construction methods is driving up the extruded polystyrene market demand for extruded polystyrene insulation. Extruded polystyrene has excellent thermal resistance, which reduces heat transmission while increasing overall building energy efficiency. Its longevity and ability to retain insulation properties over time give rise to its viability. The growing construction industry, particularly in the residential and commercial sectors, drives demand for insulation materials such as extruded polystyrene. As new buildings are built and existing ones are renovated, effective insulation becomes increasingly important in meeting energy efficiency standards and improving occupant comfort. Insulating materials, such as extruded polystyrene, are frequently used in infrastructure projects like tunnels, transit networks, and foundations to provide thermal protection, prevent condensation, and assure stability for the long term.

The COVID-19 pandemic has had a negative impact on the extruded polystyrene market development due to its dependency on the construction sector. The rising risk of infection among the workers has resulted in delaying construction projects.

- For instance, in May 2021, according to a CNA report, the Construction Industry Joint Committee (CIJC) stated that a shortage of workers could cause construction project delays, primarily affecting workplace safety and other related factors.

Furthermore, many building material manufacturers have closed or reduced their operations, causing supply chain disruptions. Furthermore, critical raw materials for producing extruded polystyrene insulation materials, such as extruded polystyrene, plastic granules, additives, and others, are obtained or leased from various businesses.

Extruded Polystyrene Market Dynamics

Market Drivers

The increasing use of extruded polystyrene in the construction sector driving the growth of the market

The rising usage of extruded polystyrene in the construction sector drives the growth of the market. There is a huge demand for extruded polystyrene in the market owing to its high strength, thermal efficiency, excellent flexibility, lightweight, and compatibility. Extruded polystyrene has long been recognized as a popular insulating material over the last decade. It has emerged as a powerful architectural design element, demonstrating that it is an excellent alternative for environmentally friendly building practices. This versatile material not only improves energy efficiency but also contributes to higher indoor air quality and durability, providing tangible environmental benefits.

Rising the application of extruded polystyrene in end-use industries

Extruded polystyrene is used in various key industries such as construction, packaging, automotive, and consumer goods. The versatility of XPS in various industries, including its use as a lightweight and durable material, is propelling extruded polystyrene market demand. As technological advancements and innovations continue to unlock new applications for extruded polystyrene, the market is experiencing growth driven by its expanding role across diverse end-use industries.

Market Restraints

Environmental concerns associated with the disposal and recycling of extruded polystyrene foam

The extruded polystyrene market faces significant challenges due to environmental concerns about the disposal and recycling of extruded polystyrene foam. Extruded polystyrene foam, which is primarily used in insulation and packaging materials, is hazardous to the environment because it is non-biodegradable. The disposal of extruded polystyrene foam in landfills contributes to long-term environmental degradation because it takes centuries to degrade, raising concerns about the accumulation of non-recyclable waste.

Furthermore, recycling extruded polystyrene presents unique challenges, as the process is only sometimes economically viable and may necessitate specialized facilities. The environmental impact of extruded polystyrene production, which utilizes fossil fuels and contributes to greenhouse gas emissions, heightens these concerns. As sustainability becomes more important in various industries, the reluctance to adopt or expand the use of extruded polystyrene could hinder the growth of the market.

Report Segmentation

The market is primarily segmented based on application, end-use, and region.

|

By Application |

By End-Use |

By Region |

|

|

|

To Understand the Scope of this Report: Speak to Analyst

Extruded Polystyrene Market Segmental Analysis

By Application Analysis

- The foundation segment held the largest extruded polystyrene market share in 2023. Extruded polystyrene insulation is widely used below building foundations owing to its exceptional thermal resistance, strong moisture resistance, and significant load-bearing capacity. This use of extruded polystyrene has assisted in improving the energy efficiency and longevity of structures, which is critical for meeting strict building codes and sustainability standards.

By End-Use Analysis

- The residential segment dominated the largest extruded polystyrene market share in 2023. Extruded polystyrene insulation is critical for increasing the energy efficiency and structural stability of residential buildings. Its applications include insulating key areas of a home, such as walls, roofs, ceilings, floors, and basements. Extruded polystyrene market demand in the residential sector is high owing to strict energy efficiency standards, building codes requiring improved insulation practices, and a growing emphasis on sustainable and eco-friendly construction techniques. Despite its widespread use in residential construction, extruded polystyrene's versatility extends to a variety of industries, highlighting its importance beyond residential applications.

Extruded Polystyrene Market Regional Insights

Europe dominated the market with largest revenue share in 2023

Europe dominated the market with the largest revenue share of the extruded polystyrene market in 2023. Europe executes stringent energy efficiency standards and building regulations, resulting in the widespread use of advanced insulation materials such as extruded polystyrene in the construction sector. The region's devotion to sustainable building practices, combined with a thriving construction industry and expanding infrastructure projects, has significantly increased demand for extruded polystyrene in a variety of applications. Furthermore, the emphasis on improving energy efficiency through the renovation of existing buildings has greatly aided the increased use of extruded polystyrene insulation. This extruded polystyrene market trend has strengthened Europe's dominance in the market.

Competitive Landscape

The market is characterized by intense competition, with established players relying on advanced technology, high-quality products, and a strong brand image to drive revenue growth. These companies employ various strategies such as research and development, mergers and acquisitions, and technological innovations to expand their product portfolios and maintain a competitive edge in the market.

Some of the major players operating in the global market include:

- BASF SE

- Dow Inc.

- Dupont de Nemours, Inc.

- Kaneka Corporation

- Kingspan Group PLC

- Owens Corning

- Ravago S.A.

- Saint-Gobain

- Synthos S.A.

- Supreme Petrochem Ltd.

Recent Developments

- In February 2023, Owens Corning expanded its presence in Arkansas by establishing a new 150,000-square-foot facility in Russellville. This expansion is expected to create 50 new jobs over two years.

- In January 2023, BASF announced plans to expand its polymer dispersion business in Merak, Indonesia. This expansion will increase the production of styrene-butadiene dispersions to meet rising demand from emerging paper mills in Southeast Asia and Oceania.

Report Coverage

The extruded polystyrene market report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, application, end-use and their futuristic growth opportunities.

Extruded Polystyrene Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 5.72 billion |

|

Revenue forecast in 2032 |

USD 7.98 billion |

|

CAGR |

4.2% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments Covered |

By Application, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region and segmentation |

FAQ's

BASF SE, Dow Inc., Dupont de Nemours, Inc., Kaneka Corporation, Kingspan Group PLC, Owens Corningare the key companies in Extruded Polystyrene Market

Extruded polystyrene market size exhibiting the CAGR of 4.2% during the forecast period

The Extruded Polystyrene Market report covering key segments are application, end-use, and region

The increasing use of extruded polystyrene in the construction sector driving the growth of the marketare the key driving factors in Extruded Polystyrene Market

The extruded polystyrene market size is expected to reach USD 7.98 Billion by 2032