Electric Motor Rotor Shaft Market Share, Size, Trends, Industry Analysis Report: By Type (Solid Shaft, Hollow Shaft, Stepped Shaft, and Others), Material Type, Application, End User, and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Nov-2024

- Pages: 116

- Format: PDF

- Report ID: PM5270

- Base Year: 2024

- Historical Data: 2020-2023

Electric Motor Rotor Shaft Market Overview

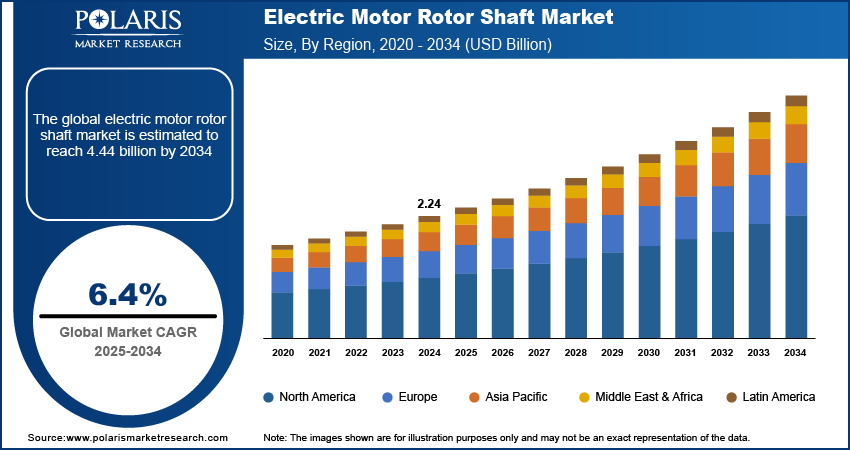

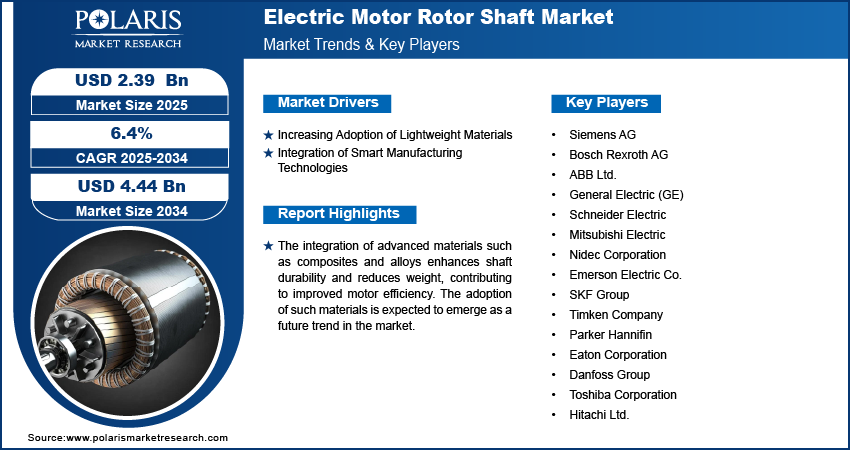

The electric motor rotor shaft market size was valued at USD 2.24 billion in 2024. The market is projected to grow from USD 2.39 billion in 2025 to USD 4.44 billion by 2034, exhibiting a CAGR of 6.4% during 2025–2034.

The global electric motor rotor shaft market growth is attributed to the increasing adoption of electric vehicles (EVs), the rising demand for energy-efficient motors across various industries, and the push toward renewable energy sources and electrification of industrial processes.

The integration of advanced materials such as composites and alloys enhances shaft durability and reduces weight, contributing to improved motor efficiency. The adoption of such materials is expected to emerge as a future trend in the market. Additionally, the ongoing advancements in manufacturing technologies, including precision engineering and automation, are playing a crucial role in optimizing production processes, thereby driving market growth.

To Understand More About this Research: Request a Free Sample Report

Electric Motor Rotor Shaft Market Drivers Analysis

Increasing Adoption of Lightweight Materials

Manufacturers are increasingly incorporating advanced composites, high-strength alloys, and carbon fiber to reduce the weight of rotor shafts. Demand for more energy-efficient motors is rising across the world, particularly in electric vehicles (EVs) as the motors help reduce the overall weight that can lead to significant energy savings and extended battery life. Lightweight rotor shafts also enhance the performance of industrial motors by minimizing inertia, leading to faster start-up times and improved operational efficiency. As industries continue to prioritize sustainability and energy conservation, the adoption of lightweight materials in rotor shafts is expected to rise in the coming years.

Integration of Smart Manufacturing Technologies

Industry 4.0 concepts such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics are being leveraged to optimize production processes, improve quality control, and reduce manufacturing costs. These technologies enable real-time monitoring and predictive maintenance of rotor shafts, ensuring consistent performance and longevity. Additionally, the use of digital twins and simulation software allows manufacturers to design and test rotor shafts virtually before physical production, reducing development time and costs. As the market continues to evolve, the adoption of smart manufacturing technologies is expected to become a key driver of innovation and competitiveness in the rotor shaft industry.

Electric Motor Rotor Shaft Market Segment Analysis

Electric Motor Rotor Shaft Market Assessment by Type Insights

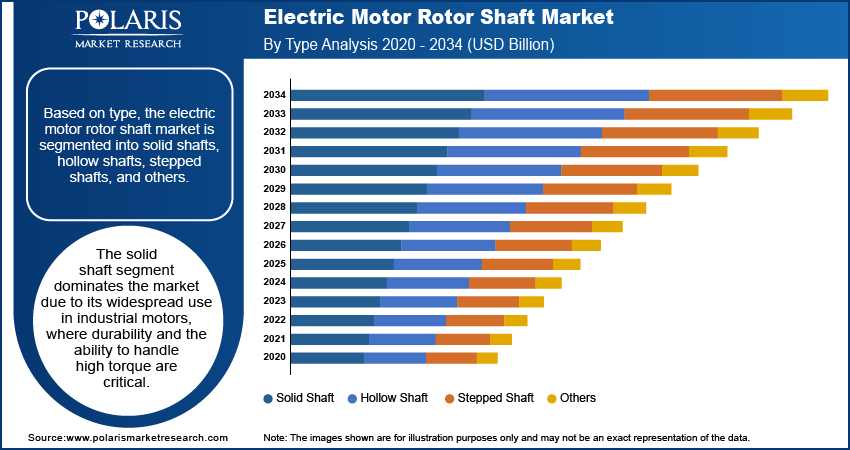

Based on type, the electric motor rotor shaft market is segmented into solid shafts, hollow shafts, stepped shafts, and others. The solid shaft segment dominates the market due to its widespread use in industrial motors, where durability and the ability to handle high torque are critical. Solid shafts are preferred for their robustness and cost-effectiveness, making them the go-to choice for heavy-duty applications, including manufacturing, mining, and transportation. Their established presence in the market and proven performance in demanding environments contribute to their leading position.

The hollow shaft segment is anticipated to witness the fastest growth in the coming years. The increasing demand for lightweight and efficient motor components, particularly in EVs and renewable energy systems, drives the adoption of hollow shafts. The shafts offer significant weight reduction without compromising strength, leading to improved motor efficiency and performance. This trend is particularly relevant in sectors focused on sustainability and energy efficiency, where reducing the overall weight of motor components is crucial. As industries continue to innovate and prioritize energy conservation, the hollow shaft segment is expected to witness substantial growth, gradually closing the gap with the solid shaft segment.

Electric Motor Rotor Shaft Market Evaluation by Application Insights

In terms of application, the electric motor rotor shaft market is segmented into industrial machinery, automotive sector, appliances, and others, with each segment catering to specific needs within these industries. The industrial machinery segment dominates the market, driven by the extensive use of electric motors in manufacturing, construction, and mining equipment. These sectors require robust and reliable motors that can withstand harsh operating conditions, making the industrial machinery segment a key contributor to market demand. The high torque and durability requirements of industrial applications make rotor shafts indispensable, contributing to this segment's leading position.

The automotive sector segment is projected to record the highest growth rate, fueled by the rapid adoption of EVs and the ongoing electrification of automotive components. As automakers shift toward sustainable and energy-efficient technologies, the demand for high-performance electric motors and their components, including rotor shafts, is surging. The rising focus of the automotive sector on reducing emissions and improving fuel efficiency is driving innovations in rotor shaft design, particularly in terms of lightweight materials and advanced manufacturing techniques. As the global EV market continues to expand, the automotive segment is expected to experience significant growth.

Electric Motor Rotor Shaft Market Share by Regional Insights

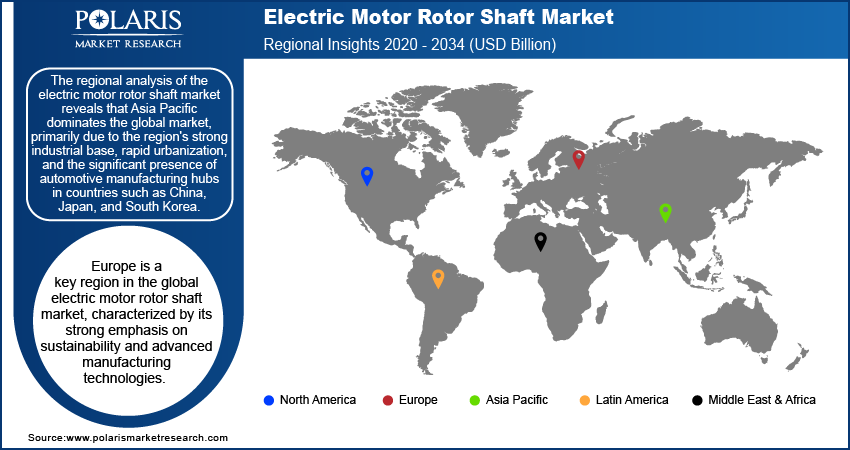

By region, the study provides market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. The regional analysis of the electric motor rotor shaft market reveals that Asia Pacific dominates the global market, primarily due to the region's strong industrial base, rapid urbanization, and the significant presence of automotive manufacturing hubs in countries such as China, Japan, and South Korea. The region's leadership in EV production and adoption, coupled with its growing focus on renewable energy, drives its dominance. Additionally, the availability of cost-effective manufacturing and abundant raw materials in Asia Pacific enhances the production capacity of rotor shafts, making it a critical hub for domestic consumption and export.

Europe is a key region in the global electric motor rotor shaft market, characterized by its strong emphasis on sustainability and advanced manufacturing technologies. The region's automotive industry, particularly in Germany, is a major driver of demand, with a growing focus on EVs and hybrid systems. European countries are also at the forefront of industrial automation and renewable energy adoption, further fueling the need for high-performance electric motors and components such as rotor shafts. Additionally, stringent environmental regulations and initiatives to reduce carbon emissions are pushing manufacturers in Europe to innovate and adopt more efficient and eco-friendly rotor shaft designs, solidifying the region's position as a significant market for these components.

Electric Motor Rotor Shaft Market – Key Players and Competitive Analysis Report

Siemens AG, Bosch Rexroth AG, ABB Ltd., General Electric (GE), Schneider Electric, Mitsubishi Electric, Nidec Corporation, Emerson Electric Co., SKF Group, Timken Company, Parker Hannifin, Eaton Corporation, Danfoss Group, Toshiba Corporation, and Hitachi Ltd are among the key players in the electric motor rotor shaft market. These companies are recognized for their extensive product portfolios, technological advancements, and global market presence. They cater to diverse sectors, including industrial machinery, automotive, and renewable energy, offering a range of rotor shaft types and designs tailored to specific applications.

Siemens AG is a global player in the electric motor rotor shaft market, renowned for its extensive portfolio of industrial automation and drive technologies. Siemens provides a wide range of high-performance rotor shafts designed for various applications such as industrial machinery and automotive systems. The company is recognized for its innovation in precision engineering and energy-efficient solutions.

Nidec Corporation is another major player known for its comprehensive range of rotor shafts used in electric motors for automotive, industrial, and consumer applications. The company is distinguished by its focus on advanced motor technologies and precision manufacturing. The company’s rotor shafts are designed to meet the demands of high-efficiency and high-performance applications.

Key Companies in the Electric Motor Rotor Shaft Market

- Siemens AG

- Bosch Rexroth AG

- ABB Ltd.

- General Electric (GE)

- Schneider Electric

- Mitsubishi Electric

- Nidec Corporation

- Emerson Electric Co.

- SKF Group

- Timken Company

- Parker Hannifin

- Eaton Corporation

- Danfoss Group

- Toshiba Corporation

- Hitachi Ltd.

Electric Motor Rotor Shaft Industry Developments

- In August 2024, Nidec unveiled a new series of rotor shafts featuring cutting-edge materials and design enhancements aimed at boosting the efficiency of EV drivetrains and reducing overall vehicle weight.

- In July 2024, Siemens announced the launch of its new line of electric motors with enhanced rotor shaft designs aimed at improving performance and reducing energy consumption in industrial applications.

Electric Motor Rotor Shaft Market Segmentation

By Type Outlook (Revenue – USD Billion, 2020–2034)

- Solid Shaft

- Hollow Shaft

- Stepped Shaft

- Others

By Material Type Outlook (Revenue – USD Billion, 2020–2034)

- Steel

- Aluminum

- Composite

- Others

By Application Outlook (Revenue – USD Billion, 2020–2034)

- Industrial Machinery

- Automotive Sector

- Appliances

- Others

By End User Outlook (Revenue – USD Billion, 2020–2034)

- OEMs

- Aftermarket

By Regional Outlook (Revenue – USD Billion, 2020–2034)

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Electric Motor Rotor Shaft Market Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 2.24 billion |

|

Market Size Value in 2025 |

USD 2.39 billion |

|

Revenue Forecast in 2034 |

USD 4.44 billion |

|

CAGR |

6.4% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global electric motor rotor shaft market size was valued at USD 2.24 billion in 2024 and is projected to grow to USD 4.44 billion by 2034.

The global market is projected to register a CAGR of 6.4% during 2025–2034.

Asia Pacific accounted for the largest market share.

Key players operating in the electric motor rotor shaft market are Siemens AG, Bosch Rexroth AG, ABB Ltd., General Electric (GE), Schneider Electric, Mitsubishi Electric, Nidec Corporation, Emerson Electric Co., SKF Group, Timken Company, Parker Hannifin, Eaton Corporation, Danfoss Group, Toshiba Corporation, and Hitachi Ltd.

The solid shaft segment dominated the market in 2024.

The industrial machinery segment accounted for the largest share of the global market.