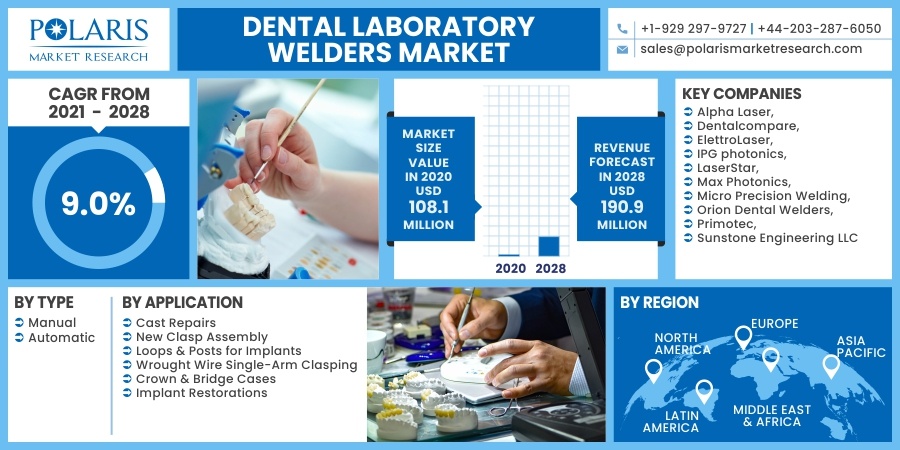

Dental Laboratory Welders Market Share, Size, Trends, Industry Analysis Report, By Type (Manual, Automatic), By Application (Cast Repairs, New Clasp Assembly, Loops & Posts for Implants, Wrought Wire Single-Arm Clasping, Crown & Bridge Cases, Implant Restorations); By Region; Segment Forecast, 2021 - 2028

- Published Date:Oct-2021

- Pages: 111

- Format: PDF

- Report ID: PM2064

- Base Year: 2020

- Historical Data: 2016 - 2019

Report Outlook

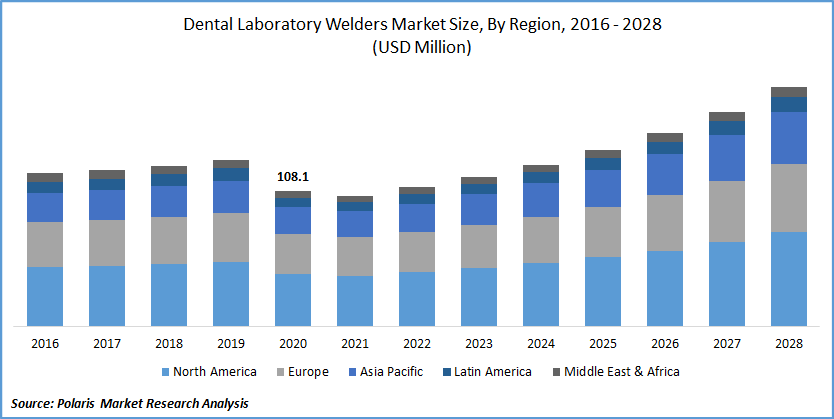

The global dental laboratory welders market was valued at USD 108.1 million in 2020 and is expected to grow at a CAGR of 9.0% during the forecast period. The growth of this market is driven by the rise in the usage of dental welding in rebuilding the distressed purpose of orofacial structures, along with the escalating market demand for dental prosthetics across the globe. Prosthetics play a prominent role in creating the huge market demand for dental laboratory welders, as it supports restoring the facial form and oral function of a patient. Furthermore, the increasing adoption of abutment placement and dental implants, coupled with the technological progression in typical welding practices, is also expanding the implementation of oral laboratory welders globally.

Welding is defined as an operation whereby two or more materials are joined by the application of heat or pressure or both. In dentistry, welding between abutment elements has been utilized by a significant number of dentists to solve issues related to laboratory distortions. The welding technique has the benefit of working with the prosthesis segment to develop prosthetic frameworks with lower distortion. Dental laboratory welders are used for several applications in dentistry, including cast repairs, new clasp assembly, crown & bridge cases, and implant restorations.

Dental labs use spot welders for repairing several dental treatments. Also, these welders can be used to heat or repair orthodontic materials by means of spot welding and electro-welding. Furthermore, they may be utilized for wire annealing, which makes the wire more ductile. Along with manual control, dental welders feature a variety of power settings. In some dental welders, a foot pedal control can be provided to allow hands-free operation. Welding machines in the dental laboratory welders market usually have a copper electrode with a carbon soldering tip. A variety of additional electrodes can be bought separately. With the continual rise in the incidence of oral care, the dental laboratory welders market demand is projected to rise over the forecast period.

Know more about this report: request for sample pages

Know more about this report: request for sample pages

The COVID-19 pandemic had a negative impact on the global laboratory welders market. Medical device manufacturers, suppliers, and logistics companies are facing significant disruptions in their business operations, which is suspending the products' deliveries. As per the article published by Mondaq, most healthcare companies are heavily relying on China for the procurement of raw materials, critical components, and complex finished medical products.

However, the constantly spreading virus-infected patients in the world have put trade restrictions on product deliveries. Thus, several market players were facing disruption in medical device production and witnessed slower down than typical growth throughout the COVID-19 crisis is indicating a collapse in the laboratory welders market valuation in recent years.

Know more about this report: request for sample pages

Industry Dynamics

Growth Drivers

The continual rise in the incidence of oral care has created a significant growth prospect for oral laboratory welders market players. Nowadays, it is increasing among the population, particularly children, due to the rise in consumption of sugary food items, insufficient health service use, and inadequate oral care procedures.

For instance: as per the Global Burden of Disease Study 2017, globally, between 60% to 90% of schoolchildren and almost 100% of grown people have tooth decay that leads to irritation and pain in teeth. Thus, the constant rise in dental care cases, coupled with growing consumer spending for maintaining health, is paving toward the dental treatment market, which eventually accelerates the market demand for dental laboratory welding machines worldwide.

Additionally, the rise in technological developments in traditional welding techniques such as soldering and brazing is also expected to accelerate the dental laboratory welders market. According to NCBI, the utilization of laser welding techniques in dentistry is demonstrating to be an efficient way of joining all metals.

Besides, laser welding is defined to promote biocompatibility with the orofacial environment and deliver a corrosion-free prosthesis. Apart from this, laser welding also offers several advantages, including high mechanical strength, low risk of contamination, and faster processing time. Hence, it plays a critical role in changing the dental laboratory welders market dynamics during the forecast period.

Report Segmentation

The market is primarily segmented on the basis of type, application, and region.

|

By Type |

By Application |

By Region |

|

|

|

Know more about this report: request for sample pages

Insight by Type

On the basis of type, the manual segment is expected to register for the largest market share in the global dental laboratory welders market during the foreseen period. The is due to the technological breakthrough in manual welding devices such as AI-enabled user interface, and distinct pulse modes are projected to propel the segmental market growth of these laboratory welders worldwide. Further, companies include Electro Laser, Orion, and Laser star specialize in producing manual dental welding machines. Thus, there is a wide use and availability witnessed in terms of the production.

Furthermore, the manual laboratory welders are also accessible at a reasonable cost in contradiction to the automatic welders. Hence, they are creating a huge implementation of such laboratory welders globally. In addition, the manual welding machines are further contrived with voluntary HDMI port enhancement to alleviate the visualization of the welding process that can be linked to the TV. This factor is also expected to drive the segment’s growth fortunes.

On the other hand, the automatic segment accounted for the fastest CAGR over the forecast period, and hence, is witnessing considerable growth throughout the world. This can be attributed to factors, such as companies like ElettroLaser producing automatic dental welding machines that can be controlled through a joystick and equipped with a cooling system and colored touch-screen features. These advancements and high precision in automatic laboratory welders are expected to propel segment growth over the foreseen period.

Insight by Application

The new clasp assembly segment is expected to witness a larger revenue share in the global laboratory welders market, owing to the rapid development of such laboratory welders’ applications, opening new opportunities for new players in the marketplace. Further, these applications are gaining wide popularity due to the increase in the requirement of welding techniques for the procedure, coupled with the extensive adoption of clasp assembly for abutment support. Hence, such benefits in this laboratory welding application are expected to generate a significant profit share that accelerates the growth of the global dental laboratory welders market.

However, the implant restoration segment is expected to register a high CAGR over the foreseen period. This is ascribed to the fact that there has been excessive acceptance of implant and its related restoration procedures. Apart from this, the significant technological advancement in these welding techniques has further resulted in increasing intra-oral welding procedures for direct retention of Osseo integrated implants, exhibiting the high growth prospect over the forecasting years.

Geographic Overview

Based on the region, North America dominated the global dental laboratory welders market in 2020 and accounted for the largest share in terms of revenue due to the extensive presence of a well-developed and matured healthcare infrastructure in the region. In addition to this, the rise in prevalence of these requirements and growing awareness among the people about restorative treatments and oral preventive is further driving the region’s growth.

According to the American Academy of Implant Dentistry (AAID), there are 3 million people have undergone dental implant treatment in the United States, and the number is continually increasing by 500,000 annually, making it a considerable opportunity for the healthcare infrastructure.

Additionally, the increasing presence of key players operating in North America, coupled with the growing product of dental care hospitals and other related health infrastructure, has further supported the overall development of the global laboratory welders market in North America.

For instance, by May 2020, 27 states authorized dental offices to open for elective care in the United States, and by June 2020, nearly 48 states commenced elective dental care. Thus, the rise in the presence of these offices in the region effectively surged the market demand for these laboratory welders to provide proper dental care and implant restoration among patients. This, in turn, is expected to expand the market growth of these laboratory welders at a rapid pace considering the global scenario.

Moreover, Asia-Pacific is likely to witness considerable growth in the global market in 2020. The demand for dental laboratory welders in the region is attributed to an increase over the forecast period, owing to the rise in economic steadiness and increasing disposable income of the individuals. Further, Asian countries have become popular for their low-cost treatment, making them a preferred laboratory welders market for medical tourism.

Thailand has been the leading country in medical and dental tourism across Asia-Pacific and the most preferred dental tourism destinations for more than 20 years. Thailand, followed by Mexico, is considered the most prominent hub for these tourism as it western countries for dental treatment. As a result, laboratory welders have gained immense acceptance, which, in turn, the laboratory welders market is gaining significant prominence worldwide.

Competitive Insight

Some of the major players operating in the global laboratory welders market are Alpha Laser, Dentalcompare, ElettroLaser, IPG photonics, LaserStar, Max Photonics, Micro Precision Welding, Orion Dental Welders, Primotec, Sunstone Engineering LLC

Dental Laboratory Welders Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2020 |

USD 108.1 million |

|

Revenue forecast in 2028 |

USD 190.9 million |

|

CAGR |

9.0% from 2021 - 2028 |

|

Base year |

2020 |

|

Historical data |

2016 - 2019 |

|

Forecast period |

2021 - 2028 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2021 to 2028 |

|

Segments covered |

By Type, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Key companies |

Alpha Laser, Dentalcompare, ElettroLaser, IPG photonics, LaserStar, Max Photonics, Micro Precision Welding, Orion Dental Welders, Primotec, Sunstone Engineering LLC |

Explore the landscape of dental laboratory welders in 2024 through detailed market share, size, and revenue growth rate statistics meticulously organized by Polaris Market Research Industry Reports. This expansive analysis goes beyond the present, offering a forward-looking market forecast till 2029, coupled with a perceptive historical overview. Immerse yourself in the depth of this industry analysis by acquiring a complimentary PDF download of the sample report.