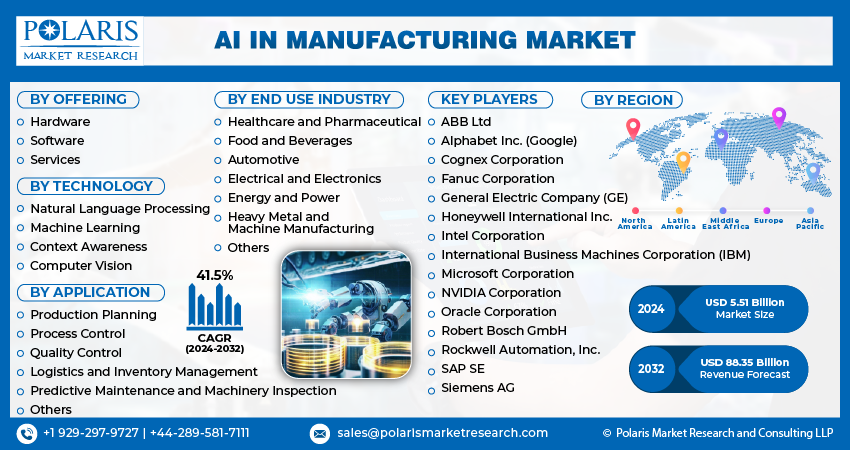

Artificial Intelligence in Manufacturing Market Share, Size, Trends, Industry Analysis Report, By Offering (Hardware, Software, Services); By Technology; By Application; By End Use Industry; By Region; Segment Forecast, 2024- 2032

- Published Date:Jan-2024

- Pages: 116

- Format: PDF

- Report ID: PM3996

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

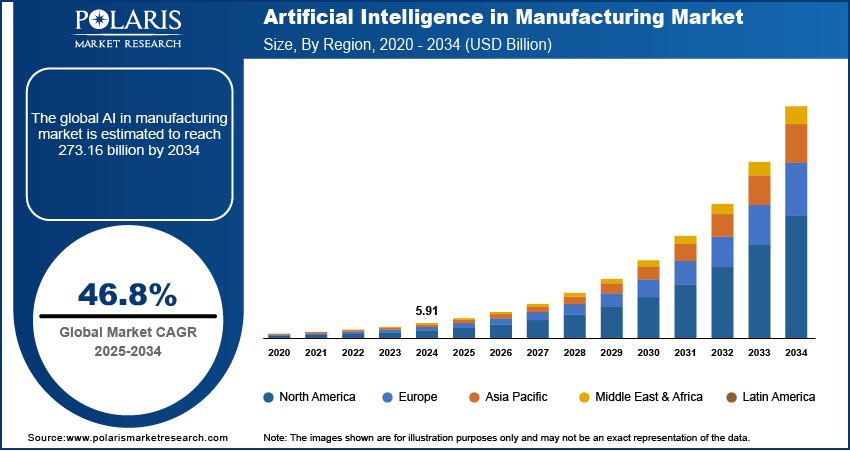

The global artificial intelligence (AI) in manufacturing market was valued at USD 3.90 billion in 2023 and is expected to grow at a CAGR of 41.5% during the forecast period.

The market research report offers an in-depth analysis of the industry to support informed decision-making. It offers a meticulous breakdown of various market niches and keeps readers updated on the latest industry developments. Along with tracking the artificial intelligence in manufacturing market on the basis of SWOT and Porter’s Five Forces models, the research report includes graphs, tables, charts, and other pictorial representations to help readers understand the key insights and important data easily.

The growth of AI in the manufacturing industry is strongly connected to the progress of machine learning algorithms and data analytics. These technologies have reached a mature stage, enabling manufacturers to extract valuable insights from vast amounts of data in real-time. With the help of AI, manufacturers can predict equipment failures, optimize production schedules, and reduce downtime, which ultimately leads to increased efficiency. Additionally, several startups are entering the market to offer enhanced solutions that cater to the growing consumer demand.

Artificial intelligence in manufacturing refers to the use of machine learning and deep learning solutions to optimize manufacturing processes. With the vast amount of data produced by industrial IoT and smart factories, AI finds several potential uses in manufacturing. Key players in the manufacturing sector are increasingly turning towards AI tools and technologies to analyze data and make better decisions. Artificial intelligence plays a key role in improving the productivity and efficiency of production processes.

There are several applications of artificial intelligence in the manufacturing landscape. A commonly cited AI use case in manufacturing is predictive maintenance, where AI technologies are applied to manufacturing data to enhance failure production and maintenance planning. That way, there’s a significant reduction in the maintenance cost for production lines. Other end uses of AI in manufacturing include production planning, process control, quality control and logistics and inventory management. With the rising emphasis on improving manufacturing efficiency, artificial intelligence (AI) in manufacturing market is projected to witness rapid growth over the forecast period.

To Understand More About this Research: Request a Free Sample Report

- For instance, SwitchOn, an India-based startup, leverages AI-powered visual inspection technologies to assist manufacturing companies in identifying product defects. Their innovative solution automates the quality inspection process, expediting quality assurance procedures and effectively eliminating production defects.

The manufacturing industry generates a vast amount of data through various sources such as IoT devices and sensors. This data availability has created an environment where AI adoption can thrive. AI systems can process this data, identify patterns, and help manufacturers make data-driven decisions. This, in turn, can aid in optimizing processes, controlling quality, and reducing costs.

The COVID-19 pandemic has significantly impacted the manufacturing industry, creating both challenges and opportunities. This pandemic exposed vulnerabilities in the global supply chain, making it difficult for manufacturers to source components and raw materials. However, AI-driven predictive analytics and supply chain optimization have become even more critical to help manufacturers adapt to disruptions and ensure business continuity.

Growth Drivers

- Greater need to enhance manufacturing efficiency, and technological advancements

Manufacturing processes can greatly benefit from AI technology, covering everything from supply chain management to production. This can lead to improved operational efficiency, reduced costs, and better resource management.

By implementing AI-driven systems for real-time quality monitoring and control, manufacturers can minimize defects and ensure consistency, ultimately raising the overall standard of product quality. Additionally, predictive maintenance powered by AI can detect machinery issues before they cause breakdowns, reducing downtime and maintenance expenses.

AI also makes mass customization possible, allowing manufacturers to meet individual customer needs while maintaining cost-effectiveness. Furthermore, AI can help manufacturers analyze large amounts of data for decision-making, process optimization, and trend analysis.

Report Segmentation

The market is primarily segmented based on offering, technology, application, end use industry, and region.

|

By Offering |

By Technology |

By Application |

By End Use Industry |

By Region |

|

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Offering Analysis

- Software segment accounted for a significant share in 2022

The software segment accounted for a significant share in 2022. Software solutions are highly versatile and adaptable, capable of being applied across a wide spectrum of manufacturing processes. Their inherent flexibility makes software the ideal choice for an industry with diverse needs. Software solutions can be developed, tested, and implemented with remarkable speed. This agility is essential in manufacturing, where the ability to respond swiftly to market shifts and technological advancements is crucial. Software solutions can be seamlessly integrated into pre-existing manufacturing systems and machinery. This minimizes disruptions and permits the gradual adoption of AI without the need for an extensive overhaul of the entire production process.

By Technology Analysis

- Machine learning segment accounted for a significant share in 2022

The machine learning segment accounted for a significant share in 2022. Machine learning plays a pivotal and transformative role in AI in manufacturing, driving innovation and operational efficiency. This technology harnesses advanced algorithms to analyze data, derive insights, and adapt, making it an asset in manufacturing. Machine learning is integral to visual product inspection, enabling automated defect detection and assuring the production of high-quality items. Cameras and sensors are deployed to examine components, while machine learning algorithms identify even the most subtle irregularities. Machine learning improves supply chain management by forecasting demand, optimizing inventory, and ensuring the punctual delivery of components. The outcome is cost savings and smoother logistical operations.

By Application Analysis

- Predictive maintenance and machinery inspection emerged as the largest segment in 2022

Predictive maintenance and machinery inspection emerged as the largest segment in 2022. AI leverages advanced algorithms and data analysis to provide manufacturers with proactive insights, ensuring optimal operational efficiency and equipment reliability. AI-driven predictive maintenance is a game-changer for manufacturers. By analyzing sensor data and historical records, AI can anticipate when machinery is likely to fail, helping companies schedule maintenance before breakdowns occur. This not only reduces downtime but also extends the lifespan of equipment and lowers maintenance costs. AI algorithms can detect subtle deviations in machinery performance, facilitating early intervention. AI-powered machinery inspection relies on computer vision and machine learning. Cameras and sensors are used to inspect components and detect defects. AI systems can rapidly analyze vast amounts of visual data, identifying even minor anomalies that might escape human observation. This level of accuracy enhances product quality and reduces the likelihood of faulty products reaching consumers.

By End Use Industry Analysis

- Automotive segment held the significant market revenue share in 2022

The automotive segment accounted for a significant share in 2022. AI technologies have become integral components of contemporary automotive manufacturing processes, facilitating efficiency enhancements and quality improvements. AI-powered robotic systems and autonomous machinery are entrusted with diverse tasks, including welding, painting, and assembly, ensuring precise and consistent operations. Computer vision systems driven by AI scrutinize vehicles for imperfections, ensuring the production of high-quality vehicles while minimizing errors. AI algorithms analyze equipment data to anticipate maintenance requirements, thereby reducing downtime and bolstering production uptime. AI optimizes supply chain management by fine-tuning inventory management, forecasting demand, and guaranteeing the timely arrival of components.

Regional Insights

- Asia-Pacific region is expected to experience highest growth during 2023-2032

The Asia-Pacific region is expected to undergo significant expansion during the forecast period. The artificial intelligence (AI) in manufacturing market in Asia-Pacific is currently experiencing remarkable growth and transformation. This sector is witnessing a significant shift as AI technologies gain rapid acceptance and integration within manufacturing industries across Asia. This technological transformation, brought about by AI, is ushering in a new era characterized by improved operational efficiency and innovative advancements. This disruptive technology is driving increased productivity, more efficient processes, and fostering innovation across a wide range of manufacturing sectors in the Asian region.

Several Asian countries, including China, Japan, South Korea, and India, are leading the way in AI adoption in manufacturing. China, as the world's leading manufacturing hub, is actively utilizing AI to optimize production workflows, enhance supply chain management, and improve product quality. Japan, known for its precision manufacturing, is deeply engaged in integrating AI to enhance operational capabilities, enabling predictive maintenance and intelligent automation. Similarly, South Korea is making significant strides in AI-driven robotics and smart factory solutions to maintain and enhance its global competitive edge.

North America accounted for a significant market share in 2022. In the U.S., AI is being integrated into precision manufacturing, enabling predictive maintenance and intelligent automation. This technology is not only enhancing the nation's competitiveness on the global manufacturing stage but also driving significant advancements in the industry. The AI in manufacturing market in the region is characterized by a dynamic ecosystem featuring startups, research initiatives, and strategic collaborations among industry leaders.

Key Market Players & Competitive Insights

The artificial intelligence in manufacturing sector exhibits a fragmented landscape, and competition is expected to intensify due to the active participation of numerous players. Prominent firms in this industry consistently introduce innovative products to bolster their market position. These key players prioritize strategies like forming partnerships, improving their product portfolios, and fostering collaborations to gain a competitive edge over their peers and establish a significant market presence.

Some of the major players operating in the global market include:

- ABB Ltd

- Alphabet Inc. (Google)

- Cognex Corporation

- Fanuc Corporation

- General Electric Company (GE)

- Honeywell International Inc.

- Intel Corporation

- International Business Machines Corporation (IBM)

- Microsoft Corporation

- NVIDIA Corporation

- Oracle Corporation

- Robert Bosch GmbH

- Rockwell Automation, Inc.

- SAP SE

- Siemens AG

Recent Developments

- In June 2023, IBASE unveiled the EC3500 edge AI computing system designed for AI applications in manufacturing and other sectors. The system is powered by the NVIDIA Jetson AGX Orin 32GB or 64 GB. It features an NVIDIA Arm Cortex A78AE v8.2 64-bit processor (offering either eight or 12 cores), along with a variety of expansion capabilities.

Artificial Intelligence in Manufacturing Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 5.51 billion |

|

Revenue forecast in 2032 |

USD 88.35 billion |

|

CAGR |

41.5% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019-2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Offering, By Technology, By Application, By End Use Industry, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region and segmentation. |

Explore the landscape of artificial intelligence in manufacturing in 2024 through detailed market share, size, and revenue growth rate statistics meticulously organized by Polaris Market Research Industry Reports. This expansive analysis goes beyond the present, offering a forward-looking market forecast till 2032, coupled with a perceptive historical overview. Immerse yourself in the depth of this industry analysis by acquiring a complimentary PDF download of the sample report.

Browse Our Top Selling Reports

Aircraft Catering Vehicle Market Size, Share 2024 Research Report

Okara Market Size, Share 2024 Research Report

Soy Grits Market Size, Share 2024 Research Report

Backlit Displays Market Size, Share 2024 Research Report

Pearl Extract Market Size, Share 2024 Research Report