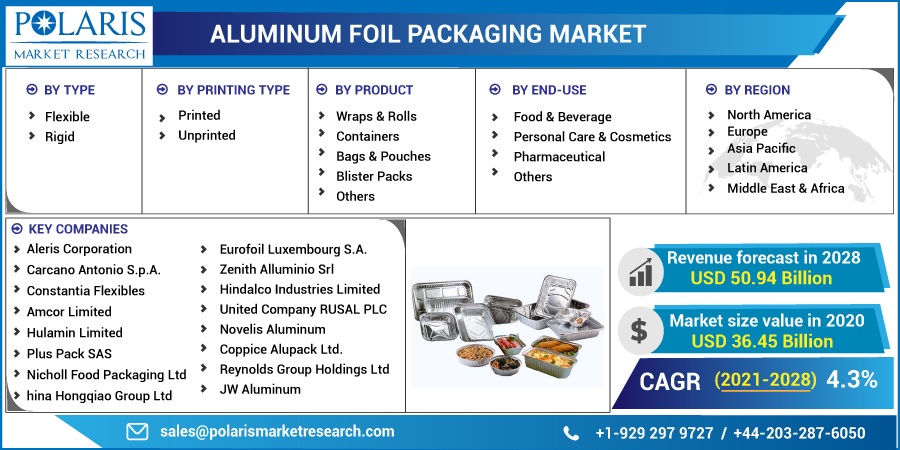

Aluminum Foil Packaging Market Share, Size, Trends, Industry Analysis Report, By Type (Flexible, Rigid); By Printing Type (Printed, Unprinted); By Product (Wraps & Rolls, Containers, Bags & Pouches, Blister Packs); By End-Use (Food & Beverage, Personal Care & Cosmetics, Pharmaceutical); By Regions; Segment Forecast, 2021 - 2028

- Published Date:Mar-2021

- Pages: 114

- Format: PDF

- Report ID: PM1808

- Base Year: 2020

- Historical Data: 2016 - 2019

Report Outlook

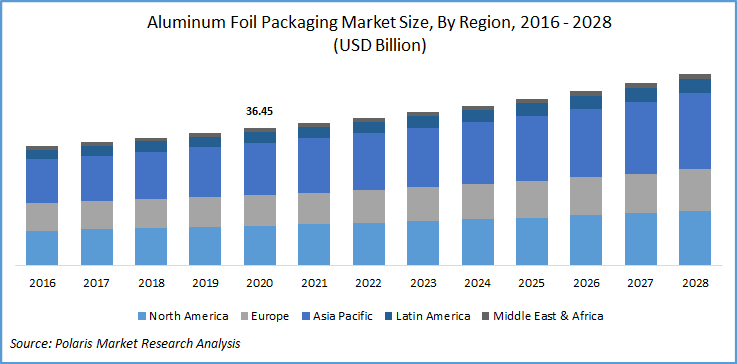

The global aluminum foil packaging market size was valued at USD 36.45 billion in 2020 and is anticipated to grow at a CAGR of 4.3% during the forecast period.

Thin but robust, and arresting due to its silvery glitter, aluminum foil is prevalent in our daily lives. Its distinct insulating attributes render aluminum foil perfect packaging for just about anything. Aluminum foil is nothing but aluminum alloy sheets that are in the middle of 0.004 and 0.24 mm thick. Aluminum foil is 8 times more attenuated than a banknote, and still, it provides ideal safeguarding against weightless, liquid, and bacteria. The aluminum foil packaging market size is expanding as it is because of these attributes. The longevity of many kinds of edibles packaged in substances that involve aluminum foil frequently surpasses 12 months.

Foil is produced in rolling mills in a procedure that includes heaving a sheet of aluminum between two gyrating rollers beneath pressure. The stemming supplementary thin sheets or foil is then severed into rolls utilizing exceptional cutters. The substance used frequently in the making of foil is unadulterated principal aluminum or 1xxx, 3xxx, and 8xxxx sequence alloys that involve silicon, iron, manganese, and, from time to time, copper if pronounced robustness is required. Warmed-up aluminum is rolled into sheets in the middle of 2 and 100 mm thick. These are then cold rolled into the foil of the needed thickness.

Aluminum packaging provides a strong solution to withstand the stresses and strains the package is exposed to during transit and storage. It is a shiny metallic, non-toxic, tasteless, odorless, and lightweight solution. It has a reflective rate of around 95% offering impermeability to bacteria, fungi, light, and moisture, significantly increasing its demand for food packaging.

The research report offers a quantitative and qualitative analysis of the aluminum foil packaging market to enable effective decision-making. It covers the key trends and growth opportunities anticipated to have a favorable impact on the market. Besides, the study covers segment and regional revenue forecasts for market assessment.

Aluminum wrapping is opaque and provides high barrier properties, restricting the transfer of light and microorganisms to package content. The increasing trend of E-commerce has driven product demand. The significant growth in demand for convenience and food products has resulted in growth in flexible and rigid segments.

Aluminum packaging solutions offer product integrity and safety while ensuring product authenticity and increased traceability. Aluminum foil is increasingly being utilized in the pharmaceutical sector for wrapping light-sensitive drugs. It offers high barrier performance, moisture resistance, anti-oxidation, greater blasting and puncture resistance, and high-temperature resistance required for effective transit of drugs.

Aluminum foil also enables effective printing on pharmaceutical packages owing to its opacity and greater light reflection. The companies operating in the market are addressing increasing safety concerns through additional security features such as tamper-proof and intelligent packaging solutions to reduce the risk of safety, theft, or counterfeiting.

Know more about this report: request for sample pages

Industry Dynamics

Growth Factors

Consumers are increasingly opting for packaging that is easy to use and convenient to transport. Smaller, lighter, and more easily disposable solutions are being used to make consumption-on-the-go easier. The increasing time-constraints, evolving lifestyles, a rising middle class in emerging markets, more women in the workforce, smaller households, and an aging population in the developed world are factors influencing the growth of the industry.

Know more about this report: request for sample pages

The high growth in e-commerce and increasing footfall in discount and convenience stores have supported the growth of the industry. Aluminum packaging is specially designed considering factors such as transit and product safety. The design of the same for e-commerce is suitable for all elements of the supply chain and presentation to consumers. The increased importance of product presentation in the retail environment, which requires higher quality packaging has increased the demand for concerned foil packaging across the globe.

Aluminum Foil Packaging Market Report Scope

The market is primarily segmented on the basis of type, printing type, product, end-use, and region.

|

By Type |

By Printing Type |

By Product |

By End-Use |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Type Outlook

On the basis of type, the market is segmented into flexible and rigid. There has been an increasing demand for flexible packaging from the food and beverages industry. Flexible foil is greatly used for wrapping chocolates, butter, cheese, and tobacco products. Owing to its temperature resistance, thermal stability, and high conduction of heat, it is used for safe and strong packaging of food products.

The growing demand for lightweight, small, and convenient packaging is driving the growth of flexible aluminum foils. The rising demand for food products such as meat, fish and poultry, confectionery, dried food, and savory snacks has supported the growth of flexible foil packaging across the globe. Pharmaceutical, medical, and cosmetics sectors also use flexible foil for efficient and lightweight packing solutions.

Printing Type Outlook

On the basis of printing type, the market is segmented into printed aluminum foil and unprinted aluminum foil. The demand for printed aluminum foil packaging is expected to increase during the forecast period owing to its high-resolution printability and aesthetic potential. Packing solutions play a significant role in elevating consumer experience and creating brand loyalty in the long term.

Brands in the market are using advanced aluminum foil packaging solutions combined with printing techniques such as flexographic and offset lithographic printing to relay marketing messages or reinforce brand loyalty. Aluminum foil packaging serves as an effective tool and a new medium of marketing.

Product Outlook

On the basis of product, the market is segmented into wraps and rolls, containers, bags and pouches, blister packs, and others. The demand for foil bags and pouches has increased for the packaging of meat products, aquatic products, frozen food, and cooked meat among others. Aluminum foil bags and pouches are strong and high barrier packaging solutions offering greater adaptability to temperature, air and moisture resistance, and durability especially for food products.

End-Use Outlook

On the basis of end-user, the market is segmented into food and beverage, personal care and cosmetics, pharmaceutical, and others. In 2020, the food and beverage segment dominated the global market. Aluminum foil packaging in the food & beverage industry contains food products while protecting them from mechanical damage, and acting as a barrier to moisture, light, and microorganisms. It also prevents or delays biological and physical degradation and facilitates efficient movement and storage.

Geographic Overview

Asia-Pacific dominated the global aluminum foil packaging market in 2020 owing to increasing population, growth in the food and beverages sector, and changing consumer preferences. Increasing demand for packaged and ready to eat meals along with increasing urban population growth, rising disposable incomes, advances in consumer awareness, a fast-growing middle class, strong growth in sectors such as fast-moving consumer goods (FMCG), pharmaceuticals, and cosmetics are the main drivers for increased demand for aluminum foil packaging in the region.

Recent Developments

-

In June 2024, global packaging company Amcor announced that the company is preparing to launch its new product named ESSENTIELLE in October 2024. ESSENTIELLE, a plastic-free foil made from aluminum and paper, has a lower carbon footprint than other solutions made of plastic on the market.

- In February 2024, Austria-based flexible packaging manufacturer Constantia Flexibles announced the acquisition of packaging producer Aluflexpack. Aluflexpack, which operates in 14 locations across Europe, specializes in foil and film packaging for the consumer and pharma markets.

Competitive Landscape

The leading players in the aluminum foil packaging market include Aleris Corporation, Carcano Antonio S.p.A., Constantia Flexibles, Amcor Limited, Hulamin Limited, Plus Pack SAS, Nicholl Food Packaging Ltd, China Hongqiao Group Limited, Eurofoil Luxembourg S.A., Zenith Alluminio Srl, Hindalco Industries Limited, United Company RUSAL PLC, Novelis Aluminum, Coppice Alupack Ltd., Reynolds Group Holdings Limited, JW Aluminum, and Aliberico S.L.U.

Seeking a more personalized report that meets your specific business needs? At Polaris Market Research, we’ll customize the research report for you. Our custom research will comprehensively cover business data and information you need to make strategic decisions and stay ahead of the curve.