Abrasive Blasting Nozzle Market Share, Size, Trends, Industry Analysis Report, By Type (Venturi Nozzle, Straight Bore Nozzle, Wide Throat Nozzle, Others), By Material, By Bore Size, By End-use, By Region, And Segment Forecasts, 2024 - 2032

- Published Date:Jan-2024

- Pages: 119

- Format: PDF

- Report ID: PM4218

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

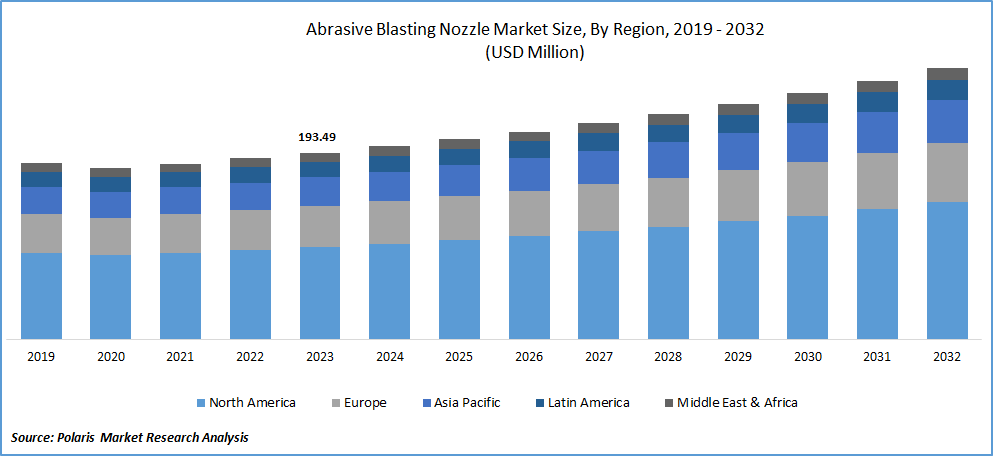

The global abrasive blasting nozzle market was valued at USD 193.49 million in 2023 and is expected to grow at a CAGR of 4.4% during the forecast period.

The sustained and steady growth in the market can be attributed to the increasing demand across diverse industries, including automotive, industrial, & marine. The importance of choosing the right nozzle for efficient results is anticipated to drive this growth. Abrasive blasting plays a crucial role in various applications, such as the removal of paint and rust from metal machinery. Nozzles come in different configurations and lengths, catering to various requirements. The selection of an appropriate nozzle depends on factors like the specific task, the surface to be cleaned, the available volume of compressed air, and the abrasive being used.

To Understand More About this Research: Request a Free Sample Report

Meeting such intricate demands requires the use of an appropriate nozzle to achieve the intended outcomes. Nozzles in abrasive blasting play a crucial role in sandblasting machines. The increasing need for such machines for tasks such as surface preparation, restoration, & graffiti removal contributes to the demand for blast nozzles. The ongoing adoption of blasting machines that can be operated remotely, aligning with the operator guidelines established by the Occupational Safety and Health Administration (OSHA), is a significant trend propelling market growth.

Nevertheless, the pandemic underscored the significance of workplace safety and health measures. Consequently, there was a heightened focus on personal protective equipment (PPE) and strict adherence to safety protocols. This surge in emphasis led to an increased demand for nozzles specifically designed to enhance worker safety, including those with advanced dust suppression features.

Industry Dynamics

Growth Drivers

Ongoing adoption of blasting machines operated remotely

The blasting nozzle holds a pivotal role in the mechanical regulation of the blasting system. It aids in optimizing the utilization of abrasives, attaining suitable blasting patterns, and efficiently using compressed air. Therefore, manufacturers prioritize routine and upfront equipment checks to ensure seamless operations and prevent unexpected downtimes. This practice not only helps in lowering overall costs but also provides significant advantages to end-users. Typically, longer nozzles are preferred unless the task requires accessing confined spaces.

Despite the basic structure of an abrasive blasting nozzle, industry participants have introduced innovative design techniques to optimize acoustic performance and enhance productivity. These design enhancements aim to provide improved coating removal, & to reduce noise emissions by nearly 15-30 dB compared to existing nozzles. These designs are expected to play a crucial role in achieving significant energy and labor cost savings. Anticipated increases in sales are attributed to the use of these nozzles in blasting operations across commercial and defense applications.

Report Segmentation

The market is primarily segmented based on type, material, end use, bore size, and region.

|

By Type |

By Material |

By End Use |

By Bore Size |

By Region |

|

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Type Analysis

Venturi nozzle segment held the largest share in 2023

Venturi nozzle held the largest share. It stands out as the most used and favored nozzle type in the abrasive blasting industry. Primarily employed for cleaning expansive surfaces, venturi nozzles come in diverse variants, including short, long, & double venturi.

The wide-throat nozzle segment is projected to grow at the fastest rate. This nozzle type, an improved version of the long venturi-style nozzle, is characterized by a spacious entry area (throat) and a generously sized exit bore. When paired with a hose of the same size, this nozzle can enhance productivity by about 15% compared to those with a smaller throat. Additionally, it can be utilized at higher pressures to produce a 60 percent larger pattern with reduced abrasive consumption when equipped with delivering the exit bore.

By Material Analysis

Carbide tips segment registered the largest market share in 2023

Carbide tips segment accounted for the largest share. Carbide nozzles, including variants such as tungsten carbide, boron carbide, and silicon carbide, are preferred due to their cost-effectiveness and durability compared to other materials. Carbide tips provide exceptional precision and control during abrasive blasting, thanks to their sharp cutting edges. This allows for accurate targeting and removal of specific areas, facilitating selective surface treatment with minimal material loss. The precision offered by carbide tips contributes to achieving desired surface finishes and enhances overall blasting efficiency.

The steel tips segment will grow at a substantial pace. These tips are predominantly utilized with siphon sandblaster units. The lower pressure to which the nozzle is exposed, compared to high-pressure alternatives, results in reduced wear. Additionally, their angular shape and hardness contribute to high cleaning efficiency, allowing them to effectively eliminate coatings, rust, and contaminants from a variety of surfaces, including metal, concrete, and wood.

By Bore Size Analysis

3/8-inch segment registered the largest market share in 2023

The 3/8-inch segment accounted for the largest share. This bore size is widely used to achieve an effective blast pressure with a 185 CFM compressor. The choice of a nozzle with a suitable bore size is contingent on the specific application. For instance, a tighter blast necessitates the need for a smaller bore size, while applications involve larger surfaces with larger opening nozzles.

The 7/16-inch segment will grow at a substantial pace. Nozzles with a 7/16-inch bore size have a larger opening and require more airflow. These nozzles are generally suitable for applications involving larger surfaces. The choice of bore size is determined by the available air pressure and flow to ensure maximum productivity.

Regional Insights

APAC region held the largest share of the global market in 2023

APAC region dominated the market. The robust expansion of the construction industry in the region primarily drives the region's growth. Furthermore, it is anticipated to be the fastest-growing market during the forecast period, propelled by intensive construction activities in emerging economies in Southeast Asia. The increasing need for abrasive blasting machines in key industries such as automotive, aerospace, & other industrial applications is expected to boost the regional market's growth further.

MEA is expected to grow at the fastest rate. This projection is attributed to the considerable industrial development observed in sectors like oil and gas, construction, manufacturing, & infrastructure in the region. These industries frequently necessitate abrasive blasting for tasks such as cleaning, surface preparation, & maintenance. With the rise in industrial activities, there is a corresponding increase in the demand for abrasive blasting nozzles.

Key Market Players & Competitive Insights

The abrasive blasting nozzle market is highly fragmented in nature, with the robust presence of global market players. The key players operating in the market are heavily investing in research & development activities in order to improve their product offerings continuously and also focusing on several business development and expansion strategies, including partnerships, collaborations, and acquisitions.

Some of the major players operating in the global market include:

- Kennametal Inc.

- Marco International Group LLC

- CLEMCO

- Sponge-Jet Inc.

- Elcometer Limited

- Everblast

- BlastOne International

- Contracor

- Manus Abrasive Systems Inc.

- Graco Inc.

- AGSCO Corporation

- Airblast B.V.

- Burwell Technologies

- KEIR Manufacturing, Inc.

Recent Developments

- In March 2023, Kennametal added the Blast Ninja nozzle to a wide variety of abrasive nozzles designed for advanced surface preparation. Created by Oceanit, an innovative 'Mind to Market' firm located in Honolulu.

- In January 2022, Fab-Tek of Central Mississippi procured a blast room from the Titan Abrasive Systems. The main goal in obtaining this enhanced blast room is to optimize the cleaning & refining procedures for the stainless-steel conveyor systems, which are the focal point of the company's design & manufacturing activities.

- In February 2021, Elcometer unveiled an extensive range of abrasive blast equipment. This comprehensive line-up includes dry abrasive blast machines, blast nozzles, media valves, blast hoses, & protective gear.

Abrasive Blasting Nozzle Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 200.03 million |

|

Revenue forecast in 2032 |

USD 281.62 million |

|

CAGR |

4.4% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD million and CAGR from 2024 to 2032 |

|

Segments covered |

By Type, By Material, By End Use, By Bore Size, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

Explore the market dynamics of the 2024 Abrasive Blasting Nozzle Market share, size, and revenue growth rate, meticulously examined in the insightful reports crafted by Polaris Market Rersearch Industry Reports. The analysis of Abrasive Blasting Nozzle Market extends to a comprehensive market forecast up to 2032, coupled with a retrospective examination. Avail yourself of a complimentary PDF download to sample this in-depth industry analysis.

Browse Our Bestselling Reports:

Marketing Attribution Software Market Size, Share Research Report

Cloud ERP Market Size, Share Research Report

Satellite Internet Market Size, Share Research Report

FAQ's

The global abrasive blasting nozzle market size is expected to reach USD 281.62 million by 2032

Marco International, CLEMCO, Sponge-Jet, Elcometer Ltd, Everblast are the top market players in the market.

APAC region contribute notably towards the global Abrasive Blasting Nozzle Market.

The global abrasive blasting nozzle market is expected to grow at a CAGR of 4.4% during the forecast period

The Abrasive Blasting Nozzle Market report covering key segments are type, material, end use, bore size, and region.