4D Printing Market Size, Share, Trends, Industry Analysis Report – By Material (Programmable Carbon Fiber, Programmable Wood – Custom Printed Wood Grain, and Programmable Textiles), Application, and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Feb-2025

- Pages: 120

- Format: PDF

- Report ID: PM1637

- Base Year: 2024

- Historical Data: 2020-2023

4D Printing Market Overview

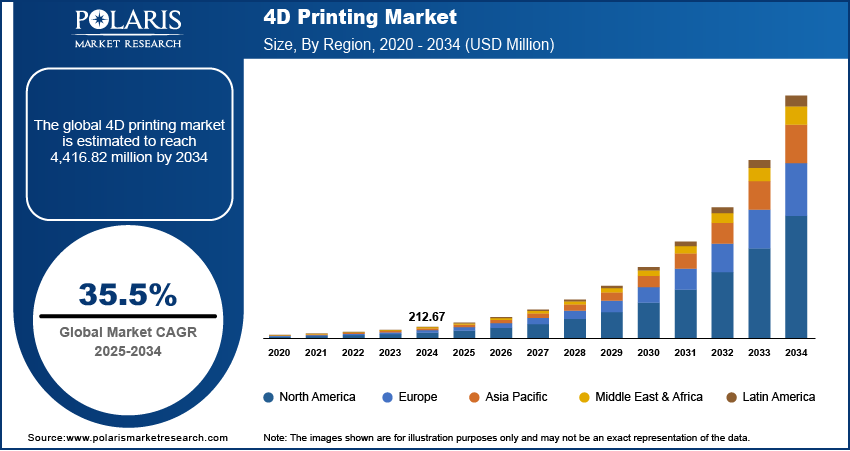

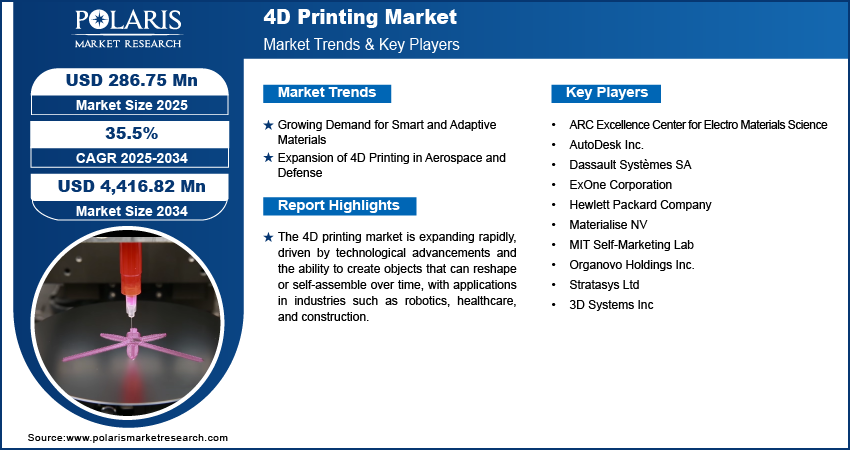

The global 4D printing market size was valued at USD 212.67 million in 2024. The market is projected to grow from USD 286.75 million in 2025 to USD 4,416.82 million by 2034, exhibiting a CAGR of 35.5% during 2025–2034.

The 4D printing market focuses on the development and application of 3D printing technologies that enable printed objects to change shape or adapt over time in response to external stimuli. The 4D printing market demand is attributed to the increasing awareness and a strong focus on technological advancements. The rising adoption of additive manufacturing has boosted demand, while increased investments in research and development, along with ongoing innovation, are further accelerating market expansion. A growing recognition of 4D printing's potential across various industries is also contributing to its rapid growth. One of the key factors propelling market growth is the reduction in processing and manufacturing costs, driven by intense competition among major market players. Additionally, the ability of 4D printing technology to produce objects that can reshape or self-assemble over time is seen as a major advantage for industries such as robotics, construction, and furniture. For instance, in June 2023, researchers at Universidad Carlos III de Madrid developed a 4D printer for biomedical applications. The printer enables shape-changing materials to respond to magnetic fields and mechanical deformation, paving the way for innovations in soft robotics, smart sensors, and cellular communication substrates. These advancements and applications are expected to play a significant role in further driving the 4D printing market expansion.

To Understand More About this Research: Request a Free Sample Report

4D Printing Market Dynamics

Growing Demand for Smart and Adaptive Materials

The growing demand for smart and adaptive materials drives the 4D printing market growth by enabling the creation of dynamic structures that respond to environmental stimuli such as temperature, light, or moisture. Many industries such as aerospace, healthcare, and automotive increasingly require materials with capabilities such as shape memory, self-healing, and controlled transformations to enhance product functionality and durability. 4D printing leverages advanced materials to produce innovative solutions, such as responsive medical implants, self-repairing materials, and adaptive components. In February 2024, a Mizzou Engineering team developed a 4D-printed personalized medical implant using bioresorbable shape memory elastomer to promote soft tissue regeneration. This innovation has potential applications in cardiovascular treatment and other soft tissue-related conditions. This synergy between material innovation and 4D printing technology fuels the 4D printing market development, addressing evolving industry needs for efficiency and sustainability.

Expansion of 4D Printing in Aerospace and Defense

The 4D printing market is experiencing growth, particularly driven by advancements in the aerospace and defense sectors. The integration of shape-memory techniques in 4D printing plays a key role in the creation of self-deploying structures, a critical application in aerospace. In the defense industry, rapid technological evolution is unlocking numerous benefits, with 4D printing enabling the production of materials that can reconstruct and self-replicate. For example, it can be used to create adaptive uniforms for soldiers that respond to environmental conditions, such as changing color, providing camouflage in different climates, or manufacturing machinery and weaponry capable of resisting toxic gases. These advancements in 4D printing technology promise to revolutionize the sector, offering materials that can repair and replicate themselves in response to dynamic environmental factors. In May 2022, Airbus Defense and Space selected 3D Systems to manufacture crucial components for its groundbreaking satellite innovation, OneSat. This collaboration underscores the aerospace industry's commitment to integrating advanced manufacturing technologies, such as 4D printing, to enhance component performance and adaptability. Additionally, the transformative capabilities of 4D printing are expected to improve quality, efficiency, and operational performance, driving 4D printing market growth in the aerospace and defense industries.

4D Printing Market Segment Analysis

4D Printing Market Assessment by Material Outlook

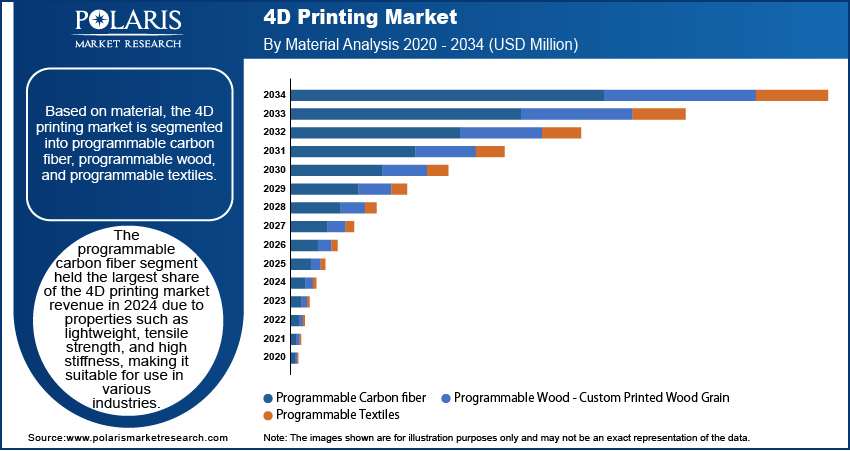

Based on material, the 4D printing market segmentation includes programmable carbon fiber, programmable wood - custom printed wood grain, and programmable textiles. The programmable carbon fiber segment held the largest 4D printing market share in 2024 due to properties such as lightweight, tensile strength, and high stiffness, which makes it suitable for use in various industries such as aerospace & defense, therapeutics, automotive, and construction & architecture. Demand for programmable wood and programmable textiles is likely to grow at a robust pace during the forecast period. The textiles industry has found the use of 4D Printing in furniture design, product manufacturing, and shipping. Improving self-transforming structures that revamp into pre-programmed shapes is perfectly feasible by printing material in differing layer thicknesses on stretched textiles. 4D technology is beneficial to produce items capable of reshaping or self-assembling over time.

4D Printing Market Evaluation by Application Outlook

The global 4D printing market segmentation, based on application, includes automotive, aerospace and defense, healthcare & biomedical, construction & architecture, consumer goods, electronics, and others. The automotive sector is expected to witness the highest 4D printing market demand during the forecast period due to the increasing need for advanced, adaptive materials that can improve vehicle performance and safety. 4D printing enables the creation of components that can change shape or properties in response to environmental factors, offering potential applications in self-healing parts, adaptive interiors, and energy-efficient components. 4D printing contributes to the development of next-generation automotive solutions with a growing focus on lightweight materials, sustainable manufacturing, and smart vehicle technologies. The sector's ongoing innovations and the push for customized, high-performance vehicles are driving the 4D printing market demand in automotive applications.

4D Printing Market Share Regional Analysis

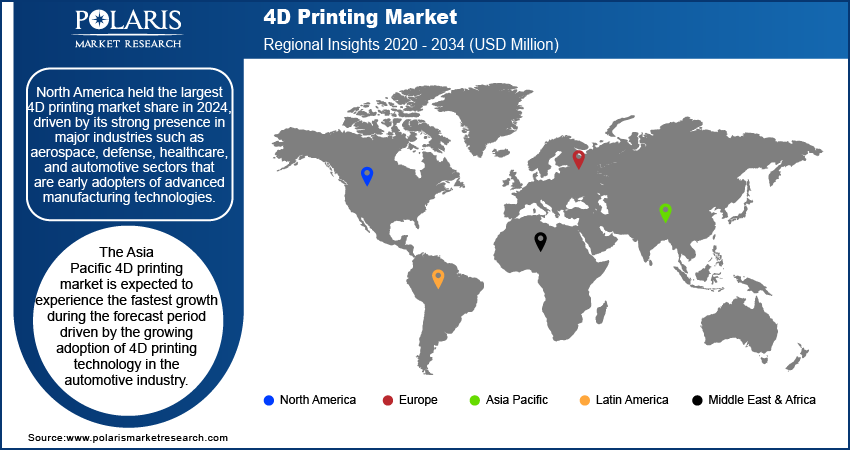

By region, the study provides the 4D printing market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America held the largest 4D printing market share in 2024, driven by its strong presence in major industries such as aerospace, defense, healthcare, and automotive sectors that are early adopters of advanced manufacturing technologies. The region benefits from investments in research and development, which boost innovation in 4D printing applications. Furthermore, North America has a well-established infrastructure for manufacturing, with leading companies and research institutions continuously driving technological advancements. Government initiatives and funding play a crucial role in supporting the growth of 4D printing technologies in the region, enabling the development of customized solutions, adaptive materials, and self-repairing components across various sectors. The automotive sector’s strong performance further supports this dominance. For instance, according to the International Organization of Motor Vehicle Manufacturers, the US produced 10,060,339 vehicles in 2024, reflecting a 10% growth from last year. North America is poised to maintain its leadership during the forecast period with a continued focus on smart manufacturing and sustainability.

The Asia Pacific 4D printing market is expected to experience the fastest growth during the forecast period, driven by the growing adoption of 4D printing technology in the automotive industry. This technology is increasingly being used in the production of luxury vehicles and passenger cars. The rising demand for automobiles in developing and developed nations is expected to fuel market revenue growth in the coming years. The regional market is projected to expand rapidly with a significant increase in the manufacturing of new products. Technological advancements in the region are also anticipated to play a key role in driving revenue generation in the future.

4D Printing Market – Key Players and Competitive Analysis Report

The competitive landscape of the global 4D printing market is characterized by a mix of well-established global players and emerging regional brands. The market players aim to capture market share through innovation, strategic partnerships, and regional expansion. Leading companies such as Stratasys, 3D Systems, and Autodesk leverage strong research and development capabilities, extensive distribution networks, and diverse technology portfolios to offer a wide range of advanced 4D printing solutions. 4D printing market trends reflect increasing demand for adaptive materials, self-repairing components, and customized solutions, showcasing advancements in design and functionality. The market is projected to experience significant growth, driven by rising adoption across industries such as aerospace, automotive, healthcare, and defense, where the need for smart, functional, and sustainable solutions is on the rise. Regional players, particularly in North America and Asia Pacific, are capitalizing on local market opportunities and technological developments, offering innovative products to meet the growing demand. 4D printing market competitive intelligence and strategy include mergers and acquisitions, collaborations with key industries, and the development of next-generation materials to address evolving consumer and industrial needs. These developments highlight the importance of technological innovation, industry-specific applications, and regional dynamics in propelling the 4D printing market expansion. A few major players in the 4D printing market are ARC Excellence Center for Electro Materials Science, AutoDesk Inc., Dassault Systèmes SA, ExOne Corporation, Hewlett Packard Company, Materialise NV, MIT Self-Assembly Lab, Organovo Holdings Inc., Stratasys Ltd, and 3D Systems Inc.

Autodesk, Inc. is an American multinational software corporation headquartered in San Francisco, California. Established in 1982 by John Walker, the company is known for its flagship product, AutoCAD, which revolutionized computer-aided design (CAD) by making it accessible to smaller firms in architecture and engineering. Over the years, Autodesk has expanded its software portfolio to include a wide array of applications across various industries, including architecture, engineering, construction, manufacturing, media, and entertainment. Notably, Autodesk's solutions enable users to visualize and simulate designs before they are built or produced, facilitating innovation and efficiency in project execution. In recent years, the company has increasingly focused on 4D printing, an advanced form of additive manufacturing that incorporates the dimension of time into the printing process. Unlike traditional 3D printing, which creates static objects, 4D printing involves materials that can change shape or function over time in response to environmental stimuli such as temperature and moisture. This technology holds significant potential for various applications, from self-assembling structures to adaptive building materials that can respond to changing conditions. Autodesk's commitment to integrating emerging technologies such as 4D printing into its software solutions reflects its mission to empower designers and engineers with innovative tools that enhance creativity and sustainability in their projects. Autodesk supports industries in leveraging 4D printing to create more dynamic and responsive products as a leader in digital prototyping and design software. This capability aligns with the company's broader vision of transforming how products are designed and manufactured, ultimately contributing to more sustainable practices across multiple sectors. Autodesk continues to push the boundaries of design and manufacturing innovation by harnessing the power of 4D printing alongside its established software tools.

Dassault Systèmes SE, commonly referred to as 3DS, is a French multinational software corporation founded in 1981 and headquartered in Vélizy-Villacoublay, France. The company specializes in developing software solutions for 3D product design, simulation, and manufacturing, serving a diverse range of industries, including aerospace, automotive, and life sciences. It has established itself as a leader in product lifecycle management (PLM) and digital manufacturing through its innovative 3DEXPERIENCE platform, with over 23,800 employees across 194 offices globally. This platform integrates various applications that facilitate collaboration and innovation among users, enabling them to create virtual twin’s digital replicas of physical entities that enhance product development and operational efficiency. In recent years, Dassault Systèmes has ventured into the realm of 4D printing, which incorporates the dimension of time into traditional 3D printing. This technology allows for the creation of objects that can change shape or function over time in response to environmental stimuli such as heat, moisture, or light. By leveraging advanced materials and smart design principles, 4D printing has the potential to revolutionize industries by enabling the production of adaptive products that can self-assemble or transform after being printed. The company’s commitment to sustainability is reflected in its corporate responsibility initiatives and its focus on improving the human experience through technology.

List of Key Companies in 4D Printing Market

- ARC Excellence Center for Electro Materials Science

- AutoDesk Inc.

- Dassault Systèmes SA

- ExOne Corporation

- Hewlett Packard Company

- Materialise NV

- MIT Self-Marketing Lab

- Organovo Holdings Inc.

- Stratasys Ltd

- 3D Systems Inc

4D Printing Industry Development

In June 2023, Zortrax developed 4D Printing technology in cooperation with ESA. For over a year, Zortrax has been a contractor of the European Space Agency (ESA) in a project aimed at developing new 4D Printing technologies for the space industry. Now, the project has been completed by the Zortax Research and Development team.

In August 2023, Tokyo University Researchers developed a new 4D printing method for more efficient and sustainable manufacturing.

In July 2023, Researchers from Queen’s University Belfast created personalized 4D-printed “smart” implants for breast cancer management. This is the first time that 4D printing has been used for the manufacturing of breast cancer implants.

4D Printing Market Segmentation

By Material Outlook (Revenue, USD Million, 2020–2034)

- Programmable Carbon Fiber

- Programmable Wood - Custom Printed Wood Grain

- Programmable Textiles

By Application Outlook (Revenue, USD Million, 2020–2034)

- Aerospace & Defense

- Therapeutics

- Automotive

- Construction & Architecture

- Electronics

- Others

By Regional Outlook (Revenue, USD Million, 2020–2034)

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

4D Printing Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 212.67 Million |

|

Market size value in 2025 |

USD 286.75 Million |

|

Revenue Forecast by 2034 |

USD 4,416.82 Million |

|

CAGR |

35.5% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Million and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

• The global 4D printing market size was valued at USD 212.67 million in 2024 and is projected to grow to USD 4,416.82 million by 2034.

• The global market is projected to register a CAGR of 35.5% during the forecast period.

• North America held the largest market share in 2024.

• A few key players in the market are ARC Excellence Center for Electro materials Science, AutoDesk Inc., Dassault Systèmes SA, ExOne Corporation, Hewlett Packard Company, Materialise NV, MIT Self-Assembly Lab, Organovo Holdings Inc., Stratasys Ltd, and 3D Systems Inc.

• The programmable carbon fiber segment held the largest market share in 2024.

• The automotive segment would experience the fastest market growth during the forecast period.