3D Metrology Market Share, Size, Trends, Industry Analysis Report, By End-Use (Aerospace & Defense, Automotive, Architecture & Construction, Medical, Semiconductor & Electronics, Energy & Power, Heavy Machinery, Mining, Others); By Product; By Application; By Offering; By Region; Segment Forecast, 2022 - 2030

- Published Date:Jan-2022

- Pages: 112

- Format: PDF

- Report ID: PM2184

- Base Year: 2021

- Historical Data: 2018 - 2020

Report Outlook

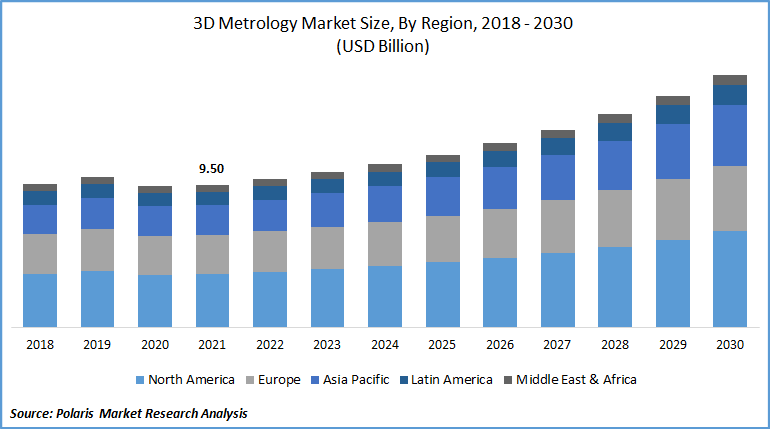

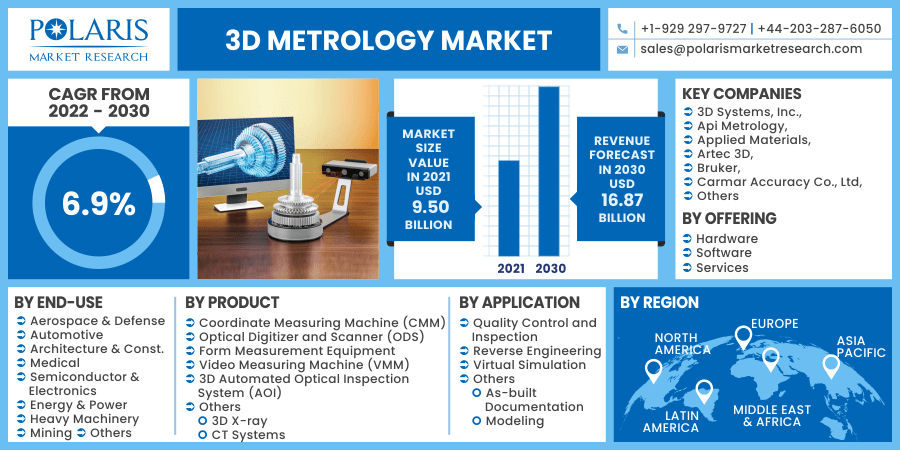

The global 3D metrology market was valued at USD 9.50 billion in 2021 and is expected to grow at a CAGR of 6.9% during the forecast period. Key factors responsible for the growth include improved R&D spending and a strong emphasis on quality control. Substantial advances in software-driven process automation and convenient metrology equipment for modified services have also generated market growth.

Know more about this report: request for sample pages

The increasing adoption of cloud computing services drives 3D metrology market growth. Every business targets to lower its operating cost and maximize its profit margins. Cloud storage avoids large capital spending on purchasing servers and physical hard drives. Manufacturing metrology, conventionally used in quality control, increasingly reaches its limits owing to the growing requirements for speed, accuracy, security, and elasticity.

Innovative manufacturing technologies such as data-driven cloud computing services are therefore extremely favored to overcome specified limitations and to meet current requirements. Thus, increasing the adoption of cloud computing services will drive the 3D metrology market growth.

Report Segmentation

The market is primarily segmented on the basis of offering, product, application, end-use, and region.

|

By Offering |

By Product |

By Application |

By End-Use |

By Region |

|

|

|

|

|

Know more about this report: request for sample pages

Insight by Offering

The hardware offering segment is anticipated to grow at the highest CAGR over the forecast period. The hardware sector is leading in the global market. Hardware equipment is continuously being adopted into the businesses such as aerospace, defense, architecture, building, medicinal, electronics, heavy machinery to sustain the quality of the product has led to the dominance of the hardware segment.

Insight by End-Use

The automotive segment is projected to hold the largest share during the forecast. These services are predominantly used in the automotive business in the early stages of the design, manufacture, and fixing of single components and finished products and the assembly of automated production lines. The process of quality control and examination is vital for production.

The automotive industry works CMMs (Coordinate Measuring Machines) and optical measurement systems for improving the safety of a vehicle. The advancement in demand for high-end vehicles, as well as fuel-efficient transport, particularly in emerging economies, is expected to drive the demand for 3-Dimensional metrology solutions over the forecast period.

Know more about this report: request for sample pages

Geographic Overview

North America was the major revenue sponsor in the global 3D metrology market. The presence of numerous automobile manufacturers such as Ford Motors, General Motors, research institutes, and huge semi-conductor corporations in this region has enlarged the demand for 3-Dimensional metrology equipment. The region is also driven by the strong presence of aerospace and pharmaceutical equipment manufacturers in the U.S. Numerous power train and body-in-white producers might exchange conventional measurement services.

Asia Pacific is likely to record a healthy market growth rate during the forecast period. This is primarily due to the presence of automotive giants in the region, surging airport establishments, and the high demand for precision metrology services and solutions. Furthermore, Singapore, Malaysia, and India have also practiced significant growth over the past few years, both in terms of adding new aerospace manufacturing services and fascinating global participants to set up shops across the region.

China is a global engineering hub. Meanwhile, the accuracy and struggle in manufacturing processes increase, the 3-Dimensional metrology software market is estimated to witness growth in this area, as China currently has many manufacturing services of national and international giants. Thus, growing investment in the Asia Pacific region for manufacturing services due to low labor costs and convenience of raw materials has boosted the market growth.

Competitive Insight

Some of the major players operating the global market are 3D Systems, Inc., Api Metrology, Applied Materials, Artec 3D, Bruker, Carmar Accuracy Co., Ltd, Cyberoptics Corp., Faro Technologies, Inc, Hexagon, Hexagon AB, Jenoptik, Keyence Corp., KLA Corporation, Metrologic Group, Mitutoyo Corporation, Renishaw, Shining 3D, and Zeiss Group. In September 2020, Hexagon’s Manufacturing Intelligence business unit released QUINDOS 2020, which is extremely flexible and powerful dimension software catering to a range of applications from standard inspection, involving special geometries.

3D Metrology Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 9.50 billion |

|

Revenue forecast in 2030 |

USD 16.87 billion |

|

CAGR |

6.9% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD million/billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Offering, By Product, By Application, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Key companies |

3D Systems, Inc., Api Metrology, Applied Materials, Artec 3D, Bruker, Carmar Accuracy Co., Ltd, Cyberoptics Corp., Faro Technologies, Inc, Hexagon, Hexagon AB, Jenoptik, Keyence Corp., KLA Corporation, Metrologic Group, Mitutoyo Corporation, Renishaw, Shining 3D, and Zeiss Group. |