3D Machine Vision Market Size, Share, Trends, Industry Analysis Report: By Offering (Hardware and Software), Product, Application, End-Use Industry, and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Nov-2024

- Pages: 129

- Format: PDF

- Report ID: PM1471

- Base Year: 2024

- Historical Data: 2020-2023

3D Machine Vision Market Overview

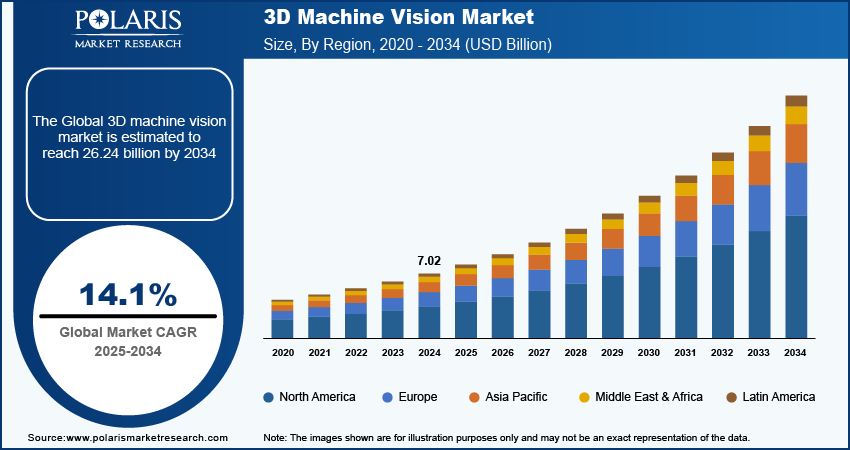

The 3D machine vision market size was valued at USD 7.02 billion in 2024. The market is projected to grow from USD 7.99 billion in 2025 to USD 26.24 billion by 2034, exhibiting a CAGR of 14.1% during 2025–2034.

3D machine vision technology represents a significant advancement in how machines perceive and interact with their environment. 3D machine vision systems utilize multiple cameras or laser sensors to gather information across three dimensions—length, width, and depth. This capability allows for a more comprehensive understanding of an object’s shape, size, and spatial orientation, making it particularly valuable in industrial applications such as manufacturing, logistics, and quality control.

The rising adoption of automation in industries drives the global 3D machine vision market. In automated systems in industries, robots are used for tasks such as picking, placing, and assembling products. 3D machine vision is an integral part of robots that allows them to better understand their environment, enabling more complex and adaptable tasks, thus driving the need for advanced vision systems. Additionally, automated systems with 3D vision enhance workplace safety by monitoring potential hazards and ensuring compliance with industry standards, thus increasing the attractiveness of 3D machine vision technologies.

To Understand More About this Research: Request a Free Sample Report

The growing production of automobiles worldwide fuels the 3D machine vision market growth. According to the European Automobile Manufacturers' Association, the world produced 85.4 million motor vehicles in 2022, a 5.7% increase from 2021. 3D machine vision systems are widely used in automotive production to perform precise inspections of components and assemblies, ensuring that each part complies with stringent quality standards and thereby reducing defects and recalls.

3D Machine Vision Market Driver Analysis

Increasing Focus on Quality Control in Industries

Industries are seeking to reduce defects and rework costs with a growing emphasis on quality. 3D machine vision systems detect flaws in real time, enabling immediate corrective actions and minimizing the number of defective products reaching the market. Therefore, the rising focus on quality control in industries propels the global 3D machine vision market growth.

Rising Popularity and Adoption of Autonomous Vehicles

Autonomous vehicles rely on 3D machine vision technologies to navigate safely as they provide detailed information about the vehicle's surroundings, including the detection of pedestrians, other vehicles, obstacles, and road conditions. Additionally, the vehicles require real-time data to make split-second decisions. 3D machine vision systems process large amounts of visual data quickly, enabling timely responses to dynamic driving conditions. Therefore, as the popularity and adoption of autonomous vehicles increase, the demand for 3D machine vision systems also spurs.

3D Machine Vision Market Segment Insights

3D Machine Vision Market Breakdown by Offering Insights

Based on offering, the 3D machine vision market is bifurcated into hardware and software. The hardware segment accounted for a major market share in 2024 due to the increasing demand for advanced imaging systems and sensor technologies. Hardware components such as cameras, lasers, and lighting systems play a crucial role in delivering high-resolution and accurate depth information in machine vision systems. Hardware manufacturers continuously innovate, offering solutions that enhance performance and reliability, thereby boosting adoption. Additionally, the push toward automation and the need for high-quality inspections in production lines contribute to the segment's dominance.

The software segment is expected to grow at a rapid pace during the forecast period. The growing focus on smart manufacturing and the Internet of Things (IoT) supports the expansion of software offerings, as organizations require adaptable solutions that seamlessly integrate with various hardware systems. Furthermore, the software segment is estimated to hold a dominant share in the coming years as industries prioritize quality control and operational optimization.

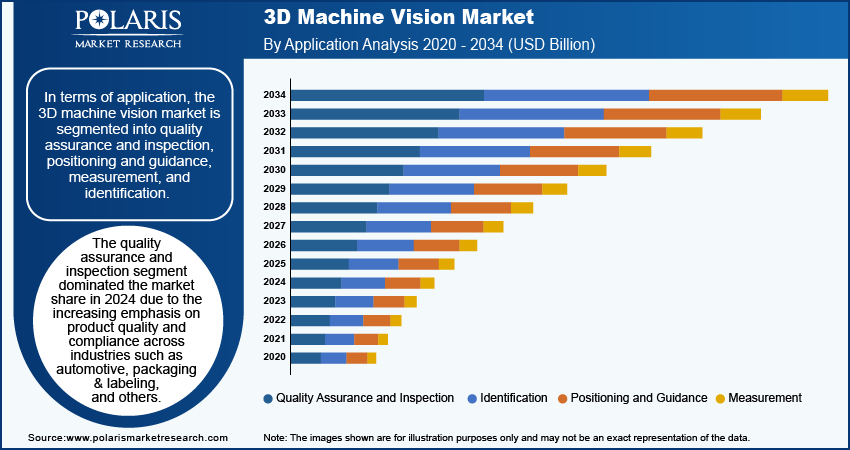

3D Machine Vision Market Breakdown by Application Insights

In terms of application, the 3D machine vision market is segmented into quality assurance and inspection, positioning and guidance, measurement, and identification. The quality assurance and inspection segment dominated the market share in 2024 due to the increasing emphasis on product quality and compliance across various industries such as automotive and packaging & labeling. Manufacturers prioritize defect detection and adherence to stringent quality standards to reduce costs associated with rework and returns. This encourages them to adopt 3D machine vision systems to conduct thorough inspections at high speeds, identifying flaws in real time. Therefore, the demand for robust quality control solutions such as 3D machine vision continues to rise as organizations aim for operational excellence, contributing to the segment's dominant position.

The identification segment is projected to grow at a rapid pace during the forecast period owing to the expansion of the e-commerce sector and the rising need for accurate order fulfillment. Businesses increasingly rely on automated systems for tracking and managing inventory, making effective identification technologies essential. Moreover, a 3D machine vision system that enhances barcode reading gains attraction as the global market shifts toward more efficient supply chain management.

3D Machine Vision Market Regional Insights

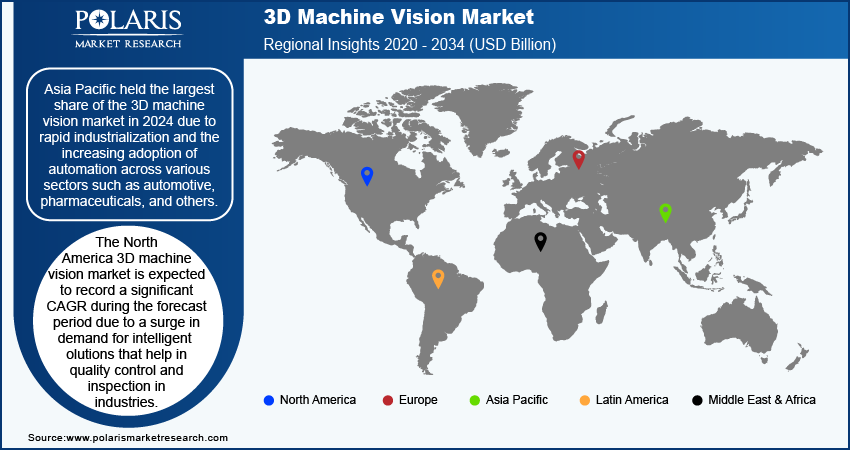

By region, the study provides the 3D machine vision market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific held the largest market share in 2024 due to rapid industrialization and the increasing adoption of automation across various sectors, such as automotive and pharmaceuticals. Countries such as China and Japan lead the growth with significant investments in manufacturing and technological development. The region's robust supply chains and high demand for advanced imaging solutions in industries such as automotive, electronics, and pharmaceuticals have propelled the expansion of the 3D machine vision market. Moreover, government initiatives aimed at enhancing manufacturing capabilities and embracing smart factory concepts have contributed to the Asia Pacific's dominance in the global 3D machine vision market.

The North America 3D machine vision market is expected to record a significant CAGR during the forecast period due to a surge in demand for intelligent solutions that help in quality control and inspection in industries. Industries in North America increasingly prioritize quality control and operational efficiency, leading to a high need for technology that integrates seamlessly with existing systems and reduces product defects. Additionally, the growing emphasis on Industry 4.0 and the Internet of Things (IoT) in the region contributes to the rising demand for 3D machine vision technologies that enhance automation and data utilization across North America.

3D Machine Vision Market – Key Players and Competitive Insights

Key 3D machine vision market players are investing heavily in research and development to expand their offerings, which will propel the market growth during the forecast period. Market participants are also undertaking a variety of strategic activities to expand their global footprint, with important market developments such as innovative launches, international collaborations, higher investments, and mergers and acquisitions between organizations.

The 3D machine vision market is fragmented, with the presence of numerous global and regional market players. NATIONAL INSTRUMENTS CORP, KEYENCE CORPORATION, Basler AG, Cognex Corporation, OMRON Corporation, Sick AG, Allied Vision Technologies GmbH, Softweb Solutions Inc. (An Avnet Company), TKH, Sony Corporation, Kitov.ai, and STEMMER IMAGING are among the major market players.

Cognex Corporation, founded in 1981, is a recognized company in machine vision technology and has significantly advanced the field of 3D machine vision with its innovative solutions designed for various industrial applications. The company has established itself as the go-to provider for high-performance machine vision solutions, with nearly one million systems installed globally. The introduction of the In-Sight L38 3D Vision System represents Cognex's commitment to integrating advanced technologies such as artificial intelligence (AI), with traditional 2D and 3D imaging techniques. This system measures objects with high precision and performs complex inspections that were previously challenging to automate.

STEMMER IMAGING, founded in 1987, is a global player in the field of machine vision, specializing in advanced imaging technologies, including 3D machine vision solutions. The company provides vision solutions across various industries, including manufacturing, logistics, and healthcare. Its offerings include a range of 3D cameras, software, and integrated systems designed to meet the diverse needs of industries.

List of top 3D Machine Vision Companies

- NATIONAL INSTRUMENTS CORP

- KEYENCE CORPORATION

- Basler AG

- Cognex Corporation

- OMRON Corporation

- Sick AG

- Allied Vision Technologies GmbH

- Softweb Solutions Inc. (An Avnet Company)

- TKH

- Sony Corporation

- Kitov.ai

- STEMMER IMAGING

3D Machine Vision Industry Developments

April 2024: Cognex Corporation, a global player in industrial machine vision, released the In-Sight L38 3D Vision System. The system combines AI, 2D, and 3D vision technologies to solve a range of inspection and measurement applications.

September 2024: Basler AG, a company that manufactures imaging components for computer vision applications, launched Pylon AI software that enhances machine vision applications by integrating AI capabilities, allowing users to implement advanced image processing and analysis.

October 2023: Kitov.ai, an Israeli-based smart visual inspection company, introduced its K-BOX line of cost-effective machine vision systems that combine AI, 3D imaging, and intelligent robotic planning technologies to solve manufacturing’s most demanding inspection applications.

3D Machine Vision Market Segmentation

By Offering Outlook (Revenue, USD Billion, 2020–2034)

- Hardware

- Software

By Product Outlook (Revenue, USD Billion, 2020–2034)

- PC Based

- Smart Camera Based

By Application Outlook (Revenue, USD Billion, 2020–2034)

- Quality Assurance and Inspection

- Positioning and Guidance

- Measurement

- Identification

By End-Use Industry Outlook (Revenue, USD Billion, 2020–2034)

- Automotive

- Pharmaceuticals & Chemicals

- Electronics & Semiconductor

- Pulp & Paper

- Printing & Labeling

- Food & Beverage

- Glass & Metal

- Postal & Logistics

- Others

By Regional Outlook (Revenue, USD Billion, 2020–2034)

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

3D Machine Vision Market Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 7.02 Billion |

|

Market Size Value in 2025 |

USD 7.99 Billion |

|

Revenue Forecast by 2034 |

USD 26.24 Billion |

|

CAGR |

14.1% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global 3D machine vision market size was valued at USD 7.02 billion in 2024 and is projected to grow to USD 26.24 billion by 2034.

The global market is projected to record a CAGR of 14.1% during the forecast period.

Asia Pacific accounted for the largest share of the global market in 2024

A few key players in the market are NATIONAL INSTRUMENTS CORP, KEYENCE CORPORATION, Basler AG, Cognex Corporation, OMRON Corporation, Sick AG, Allied Vision Technologies GmbH, Softweb Solutions Inc. (An Avnet Company), TKH, Sony Corporation, Kitov.ai; and STEMMER IMAGING.

The software segment is projected for significant growth in the global market during the forecast period.

The quality assurance & inspection segment dominated the market in 2024.